Engine-Engineandcrankcase

Thisenablesprecisetimingbeingmaintainedduringthelifeoftheengine.

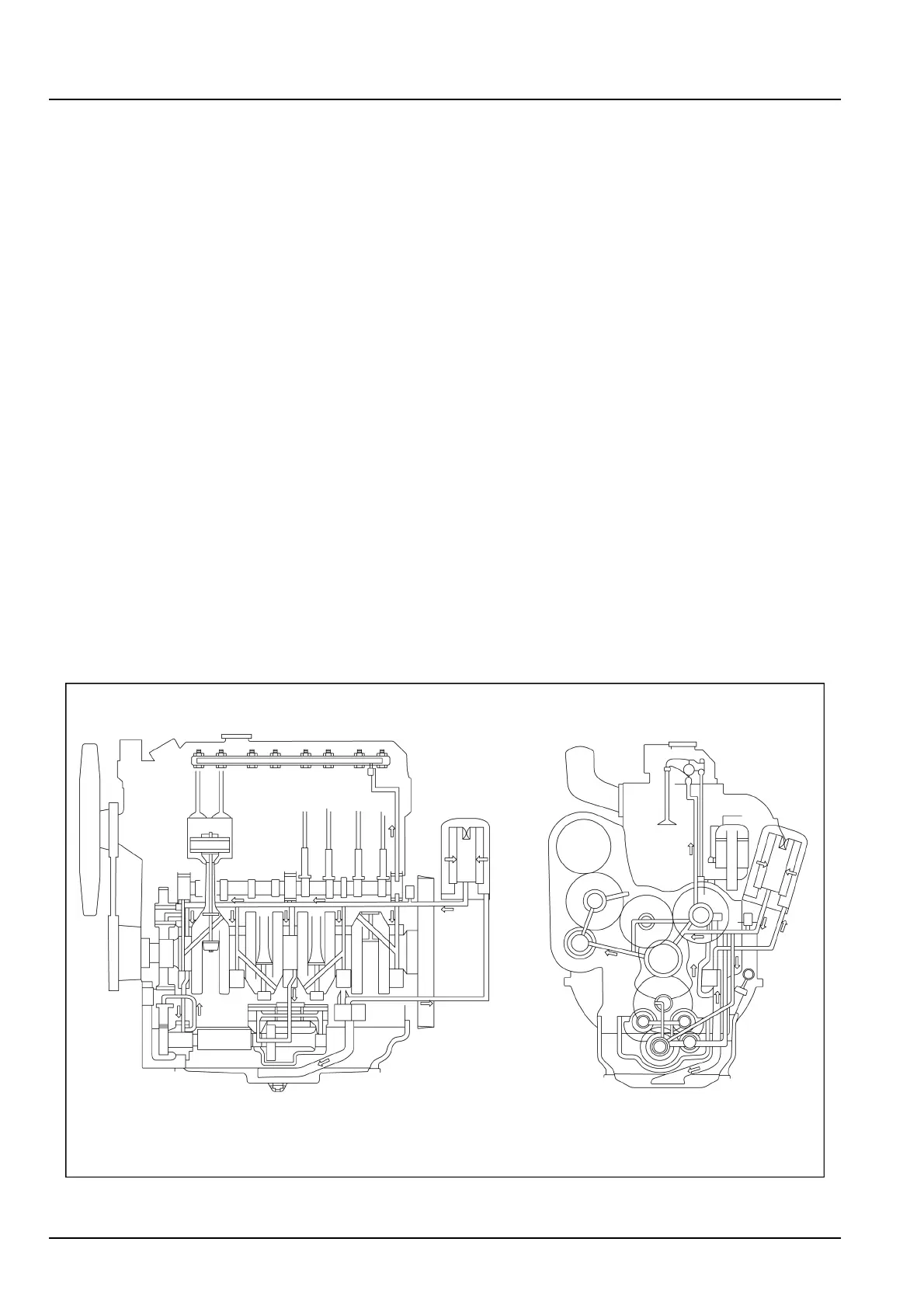

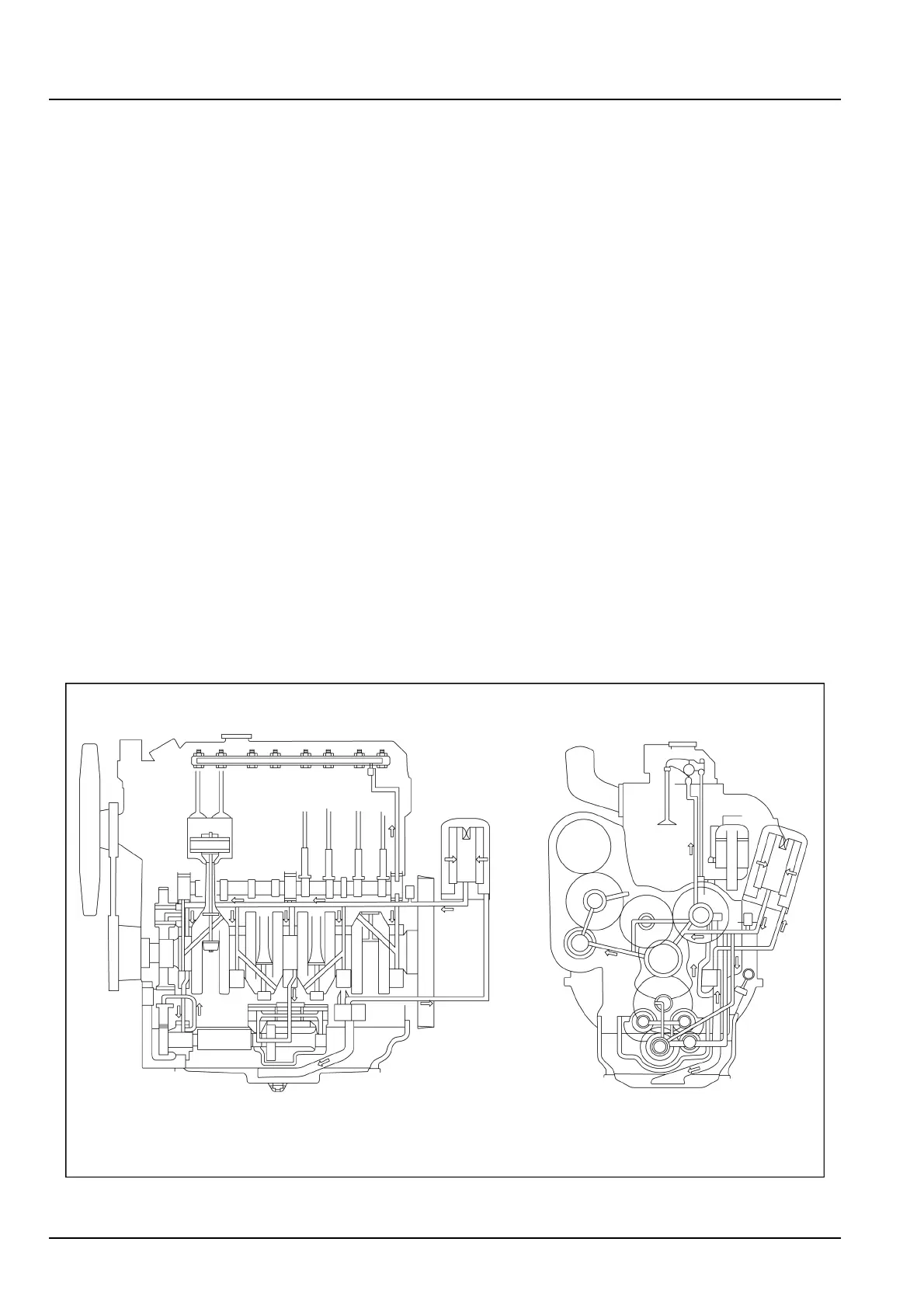

Thecrankshaftgeardrivestheidlergear,whichisattachedtothefrontofcylinderblock.

Theidlergearthendrivesthecamshaftandtheinjectionpumpviameshinghelicalgears.

Thecamshaftgearisboltedtothefrontoftheshaftandiskeyedtomaintainpositionofthegearonthecamshaft.

Lubricationsystem

Lubricationoftheengineismaintainedbyageartypeoilpumpmountedonthefrontendofthecrankshaft.

Thepumpdrainsoilfromtheengineoilsumpthroughatubeandscreenassembly.

Aspringloadedreliefvalveisintegralwiththeoillterandpreventsoverpressurizationofthesystem.

Aspinontypeoillterismountedexternallytoitssupporthousingonthelefthandsideoftheengine.

Oilowsfromtheltertothemainoilgallery,whichrunsthelengthofthecylinderblock,whichalsointersectsthe

camshaftfollowerchamber.

Themaingalleryalsosuppliesoiltothecrankshaftmainbearings,connectingrodsbothbigandsmallendsandtiming

gearbushes.

Theinnersideofthepistonsandpinsarelubricatedbyoilpressurejets(pistoncoolingnozzle).

Timinggearsarelubricatedbysplashedoilfromthecamfollowerchamberandthepressurelubricatedcamshaftdrive

gearbushing.

Anintermittentowofoilisdirectedtothevaluerockerarmshaftassemblyviaadrilledpassageinthecylinderblock.

ThisislocatedverticallyaboveNo.3camshaftbearingandalignstoaholeinthecylinderhead.Therotationofthe

camshaftallowsacontrolledintermediateowoflubrication.

PTIL13TLB0737FA2

4819054426/09/2017

10.1[10.001]/18

Loading...

Loading...