20

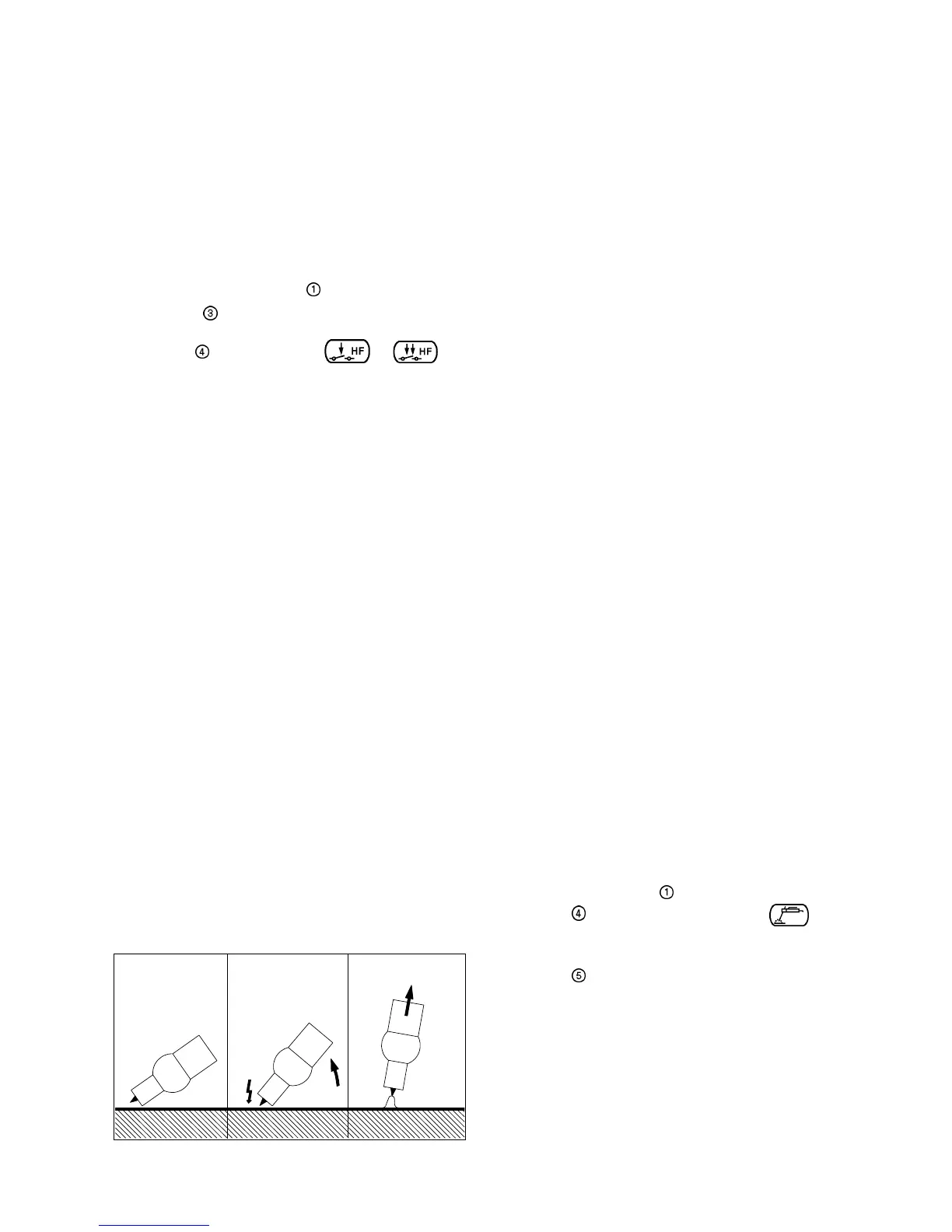

Fig. 8: Ignition assisted by HF.

a)Rest on gas nozzle

edge

b)Switch HF on c) Arc ignites

Arc ignition

o Prior to depressing th trigger, place the electrode tip

on the weld at the point where the arc is to be

ignited. Tilt the torch backwards until the edge of the

gas nozzle rests on the workpiece, and pursue until

a gap of 2 to 3 mm is obtained. Hold the position

(Fig. 8a).

o Protect your eyes with a welding helmet.

o Depress the trigger; the gas starts flowing and the

HF is on.

o The arc is lit without contact between the electrode

and the workpiece (Fig. 8b).

o Ensure a normal arc length (Fig. 8c).

Advantage: No mutual contamination, neither of

the electrode nor of the base metal.

Important: The HF is automatically switched off once

the arc column is established.

Ignition monitoring:

If, after an unsuccessful attempt to ignite the arc, or

after an arc interruption, the welder forgets to stop the

control sequence by the appropriate action on the torch

trigger (especially in 4-step mode), the shielding gas

would continue to flow, leading to considerable waste

of gas. To prevent this inconvenience, a monitoring

function automatically interrupts the control sequence

after approx. 1 second. Then a new attempt requires a

repetition of the ignition process with the torch trigger.

TIG wTIG w

TIG wTIG w

TIG w

elding in 2-steelding in 2-ste

elding in 2-steelding in 2-ste

elding in 2-ste

p modep mode

p modep mode

p mode

o Depress and hold the trigger forwards:

- Gas pre-flow (only with HF)

- Arc ignition

- Current increases up to the pre-set value

o Release the trigger:

- Current reduces down to the crater filler pre-set

value.

- Arc interrupted.

- Gas post-flow.

TIG wTIG w

TIG wTIG w

TIG w

elding in 4-steelding in 4-ste

elding in 4-steelding in 4-ste

elding in 4-ste

p modep mode

p modep mode

p mode

o Depress the trigger forwards and release it:

- Gas pre-flow (only with HF)

- Arc ignition

- Current increases up to the pre-set value.

o Depress again and hold the trigger forwards:

- Current decreases down to the crater filler pre-

set value.

- Arc maintained at low amp for filling up the

crater.

o Release the trigger:

- Arc interrupted.

- Gas post-flow.

ManMan

ManMan

Man

ual Metal ual Metal

ual Metal ual Metal

ual Metal

ArAr

ArAr

Ar

c c

c c

c

WW

WW

W

eldingelding

eldingelding

elding

Start up

o Select the polarity according to the coated stick

electrode in use.

o Plug the welding cable into the corresponding

socket and secure it by turning clockwise.

o Plug the mains cable in,

o Switch the main switch on

o Select by the corresponding process ; the

LED lights up and a welding current value appears

on the display.

o Adjust by the desired value.

o Proceed with welding.

Start up

o Fit the torch with a tungsten electrode and a gas

nozzle suitable for the application (see instruction

leaflet of the torch).

o Connect and lock the ground cable to the socket B.

o Connect the gas hose to the pressure reducer of the

gas supply.

o Plug in the mains plug.

o Switch on the main switch ,

¨ Select by the TIG or pulsed TIG process; the

LED lights up.

o Select by the control mode or the

LED lights up.

o Adjust the relevant welding parameters.

o Open the gas supply valve.

o Depress the trigger (and release it if 4-step mode).

WARNING! HF is on!

o Adjust the gas flow with the setting screw of the

pressure regulator.

o Release the trigger (depress and release it if 4-step

mode).

TIG welding with high-frequency

ignition (HF)

Loading...

Loading...