• the experience of personnel

Note: For more information on drying methods, refer

to Special Instruction, SEHS9124, “Cleaning and

Drying of Electric Set Generators”.

Remove the voltage regulator. Cover all of the inlet

openings. Cover all of the discharge holes. Provide

an opening at the top of the machine. This opening

will allow moisture to evaporate. Preferably, this

opening will be located at the fan end. Monitor the

winding temperatures. DO NOT APPLY HEAT TOO

RAPIDLY. Winding temperature should be raised

gradually at a rate of 10 °C (50 °F) per hour up to

85 °C (185 °F). Measure insulation resistance in 1

hour intervals. Typically, the insulation resistance will

slowly drop while the temperature is rising. The

insulation resistance will then start to increase at a

slow rate until the insulation resistance reaches a

constant level.

The following methods can be used for drying a

generator:

• Self-circulating air method

• Oven method

• Controlled current method

Self-Circulating Air Method

Run the engine and disconnect the generator load.

Running the engine will help circulate air. Operate the

generator space heaters.

Oven Method

Place the entire generator inside a forced air drying

oven for 4 hours at 65 °C (149 °F).

NOTICE

Use a forced air type oven rather than a radiant type

oven.

Radiant type ovens can cause localized overheating.

Controlled Current Method

Table 20

Tools Needed

Part Number Description Qty

225-8266

Ammeter Tool Gp 1

External Power Source 1

Rheostat 1

Heat can be used in order to dry the generator

windings. This heat can be created by allowing a

controlled current to flow through the generator. No

high voltages are generated during the following

procedure. Therefore, insulation breakdown will not

occur.

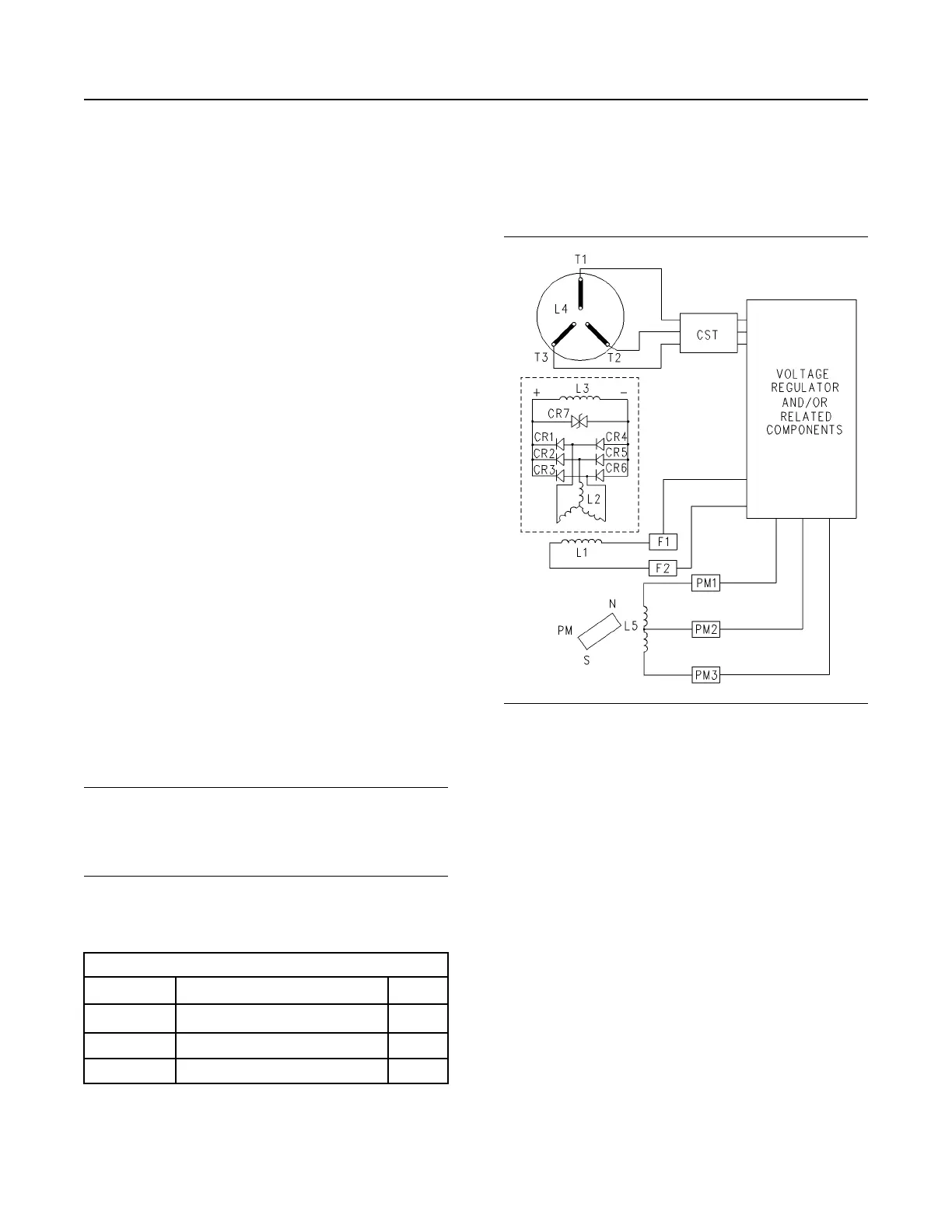

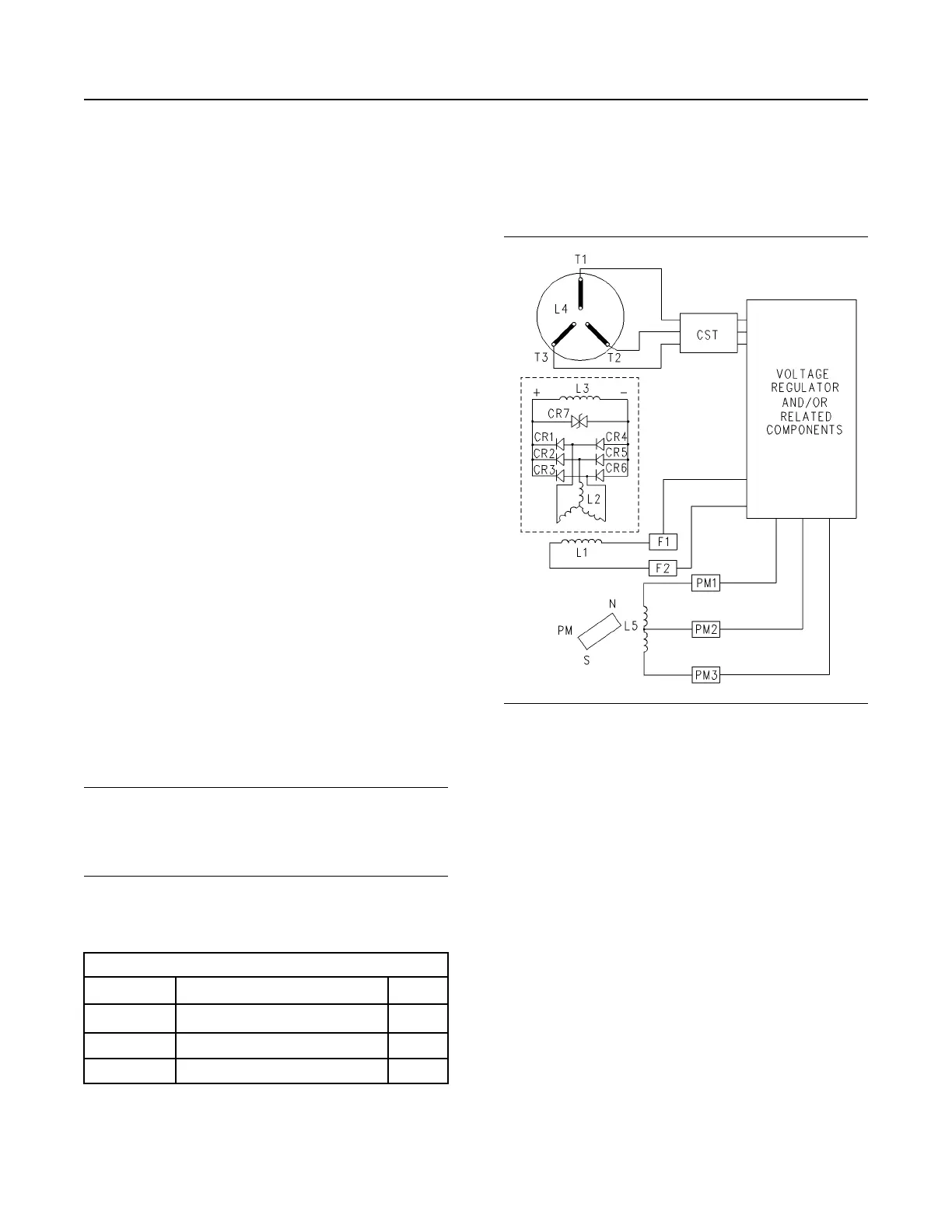

Illustration 114 g00669571

Generator Wiring Diagram

(CR1-CR6) Diodes

(CR7) Varistor

(L1) Exciter field (stator)

(L2) Exciter armature (rotor)

(L3) Main field (rotor)

(L4) Main armature (stator)

(L5) Pilot exciter armature

(PM) Permanent magnet

(RFA) Rotating field assembly

(CST) Customer supplied transformer

1. Make an external power source.

2. Refer to the above diagram. Disconnect “F1+” from

the voltage regulator. Disconnect “F2-” from the

voltage regulator. Disconnect the generator load.

Connect the generator output leads “T0” , “T1” ,

“T2” , and “T3” . Install the clamp-on ammeter to

generator output lead “T1” .

Note: When the line current is measured on multiple-

lead units, measure the current in each conductor per

phase. The currents can then be added.

SEBU7125-13

133

Maintenance Section

Generator - Dry

Loading...

Loading...