Settings

61

Boiler Protection Devices

GB

Appliance shut-o conditions

The boiler is protected from malfunctions by means of internal

checks performed by the electronic P.C.B., which stops the boiler from

operating if necessary. In the event of the boiler being shut o in this

manner, a code appears on the control panel display which refers to

the type of shut-o and the reason behind it. Two types of shut-o

may occur:

Safety shut-o

This type of error is “volatile”, which means that the boiler starts up

again automatically as soon as the problem which caused the shut-

o is removed; Err” and the error code (es. Err/108) ash on the

display and the symbol appears.

In fact, soon as the cause of the shut-o disappears, the boiler starts

up again and continues to operate normally.

If the boiler still indicates a safety shut-o, switch it o. Make sure the

external electric switch is in the OFF position, shut o the gas valve

and contact a qualied technician.

N.B. if error 1 08 - Stop due to insufficient water pressure - occurs,

simply reset the boiler pressure.

Operation shutdown

This type of error is “non-volatile”, which means that it is not removed

automatically.

On the display ash Err and the error code (es. Err/501). and

appears RESET whit the symbol .

In this case the boiler does not restart automatically, but it may be

reset by pressing the RESET button.

If the problem manifests itself again after several attempts to reset the

appliance, contact a qualied technician.

Important

For safety reasons, the boiler will allow a maximum of 5 reset

operations to take place in 15 minutes (individual presses of the

RESET button).

The rst gure of the error code (e.g. 101) indicates within which

operational assembly the error occurred.

1 - Primary Circuit

2 - Domestic Hot Water Circuit

3 - Internal Electronic Part

4 - External Electronic Part

5 - Ignition and Detection

6 - Air inlet - ue gas outlet

7 - Multizone

Anti-frost Device.

The anti-frost function acts on the central heating ow temperature

probe, independently from other settings, when the electrical supply

is turned on. If the primary circuit temperature falls below 8°C the

pump will run for 2 minutes.

After the two minutes of circulation (xed) the boiler will check the

following:

a - if the central heating ow temperature is > 8°C, the pump stops;

b - if the central heating ow temperature is between 4 and 8°C, the

pump will run for another two minutes;

c - if the central heating ow temperature is < 4°C, the burner will re

(heating position) at minimum power until the temperature reaches

33°C, the burner will go o and the pump will continue to run for two

minutes.

If the boiler is tted with a tank, a second device controls the

temperature of the domestic hot water. If this drops below 8°C,

the distributor valve switches to domestic water position and the

burner operates until the temperature reaches 12°C. This followed

by a post-circulation cycle of 2 minutes.

The anti-frost device activates only when (with the boiler operating

correctly):

- the system pressure is correct;

- the boiler is electrically powered, the symbol is illuminated;

- there is a supply of gas

- no safety shutdown or lockout is in progress.

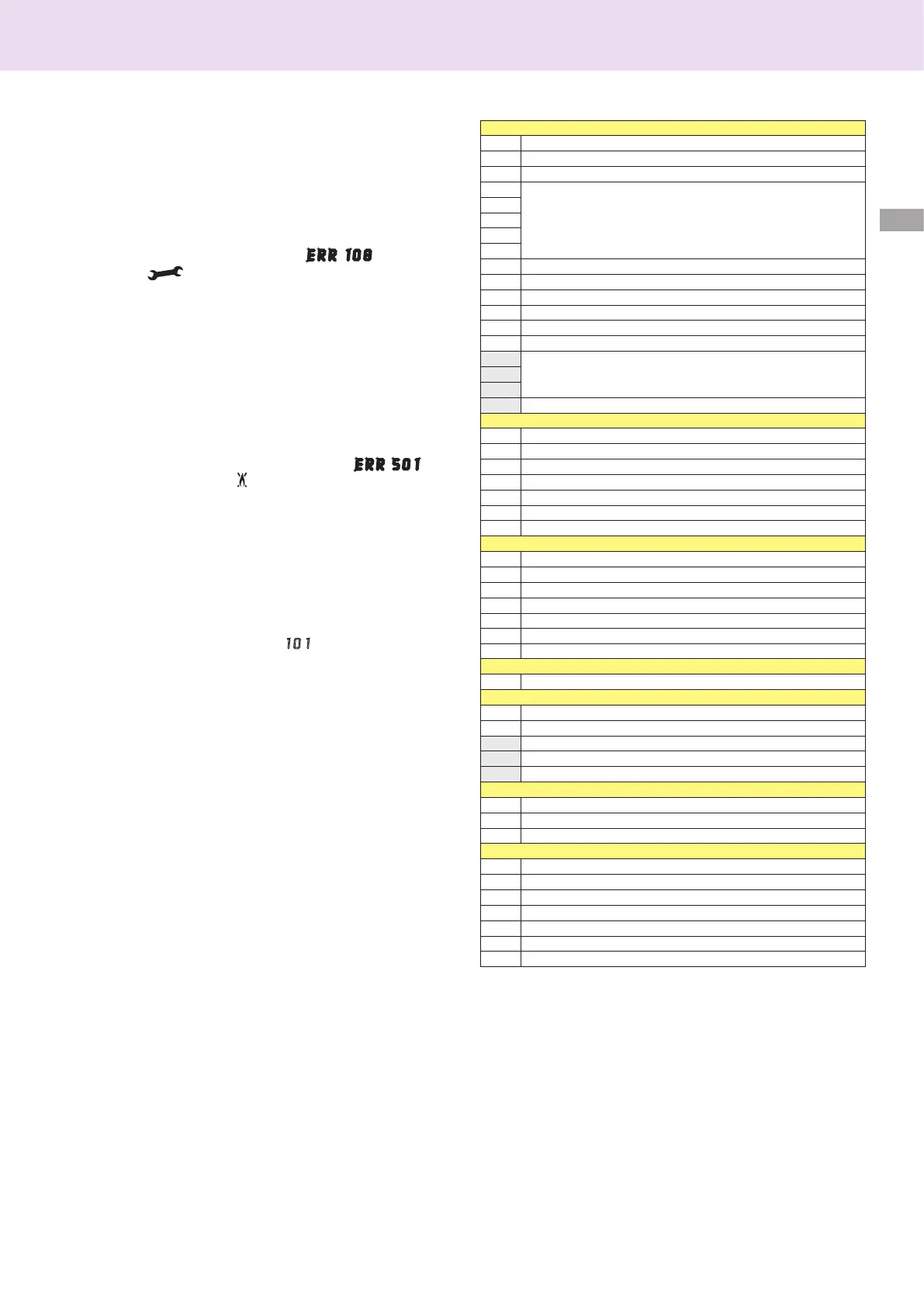

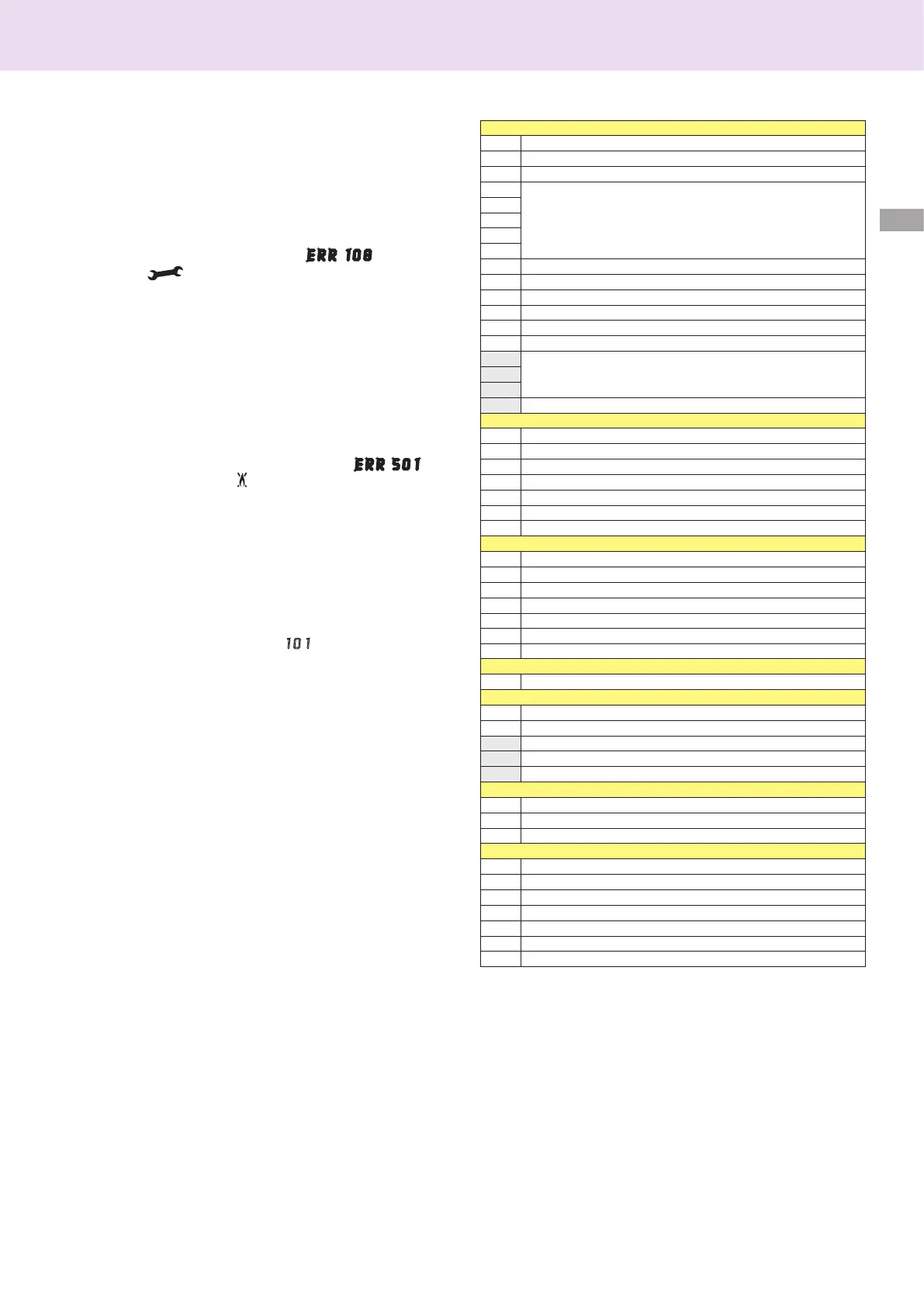

Table summarising error codes

Central Heating circuit

Display Description

101

Overheat

102

Pressure Sens Error

103

Insufficient circulation

104

105

106

107

108

Insufficient water (request lling)

109

System pressure > 3 bar

110

C.H. Flow temp. probe circuit open / short circuit

112

C.H. Return temp. probe circuit open / short circuit

114

External sensor circuit open / short circuit

118

Heating delevery probe problem

1P1

Insufficient circulation indication

1P2

1P3

1P4

Insufficient water (request lling)

D.H.W circuit

201

D.H.W. temp. probe circuit open / short circuit

202

Bottom storage temperature probe open / short circuit

203

Tank sensor probe open/short circuit

204

Solar collector temperature probe open / short circuit

207

Solar collector overheating

208

Collector frost protection temperature

209

Tank overheating

Internal P.C.B’.s

301

EEPROM error

302

Comunication error

303

Main P.C.B. error

305

Main P.C.B. error

306

Main P.C.B. error

307

Main P.C.B. error

3P9

Maintenance recommended

External P.C.B’.s

407

Room sensor circuit open 7 short circuit

Ignition and Detecion

501

No ame detected

502

Flame detected with gas valve closed

5P1

1st Ignition Failed

5P2

2nd Ignition Failed

5P3

Flame cut-o

Air Inlet / Flue gas outlet

605

Flue-gas sensor open short circuited

609

Flue-gas overheating

610

Thermal fuse open

Multi-zone Heating (Heating Zone Modules - optional)

701

Zone 2 outgoing sensor defective

702

Zone 2 return sensor defective

703

Zone 3 outgoing sensor defective

704

Zone 3 return sensor defective

705

Hydraulic separation sensor defective

706

Zone 2 overheating

707

Zone 3 overheating

Loading...

Loading...