Installation

COLD

WATER

A drain water tempering eld installation kit P/N 1117084 is included with the machine.

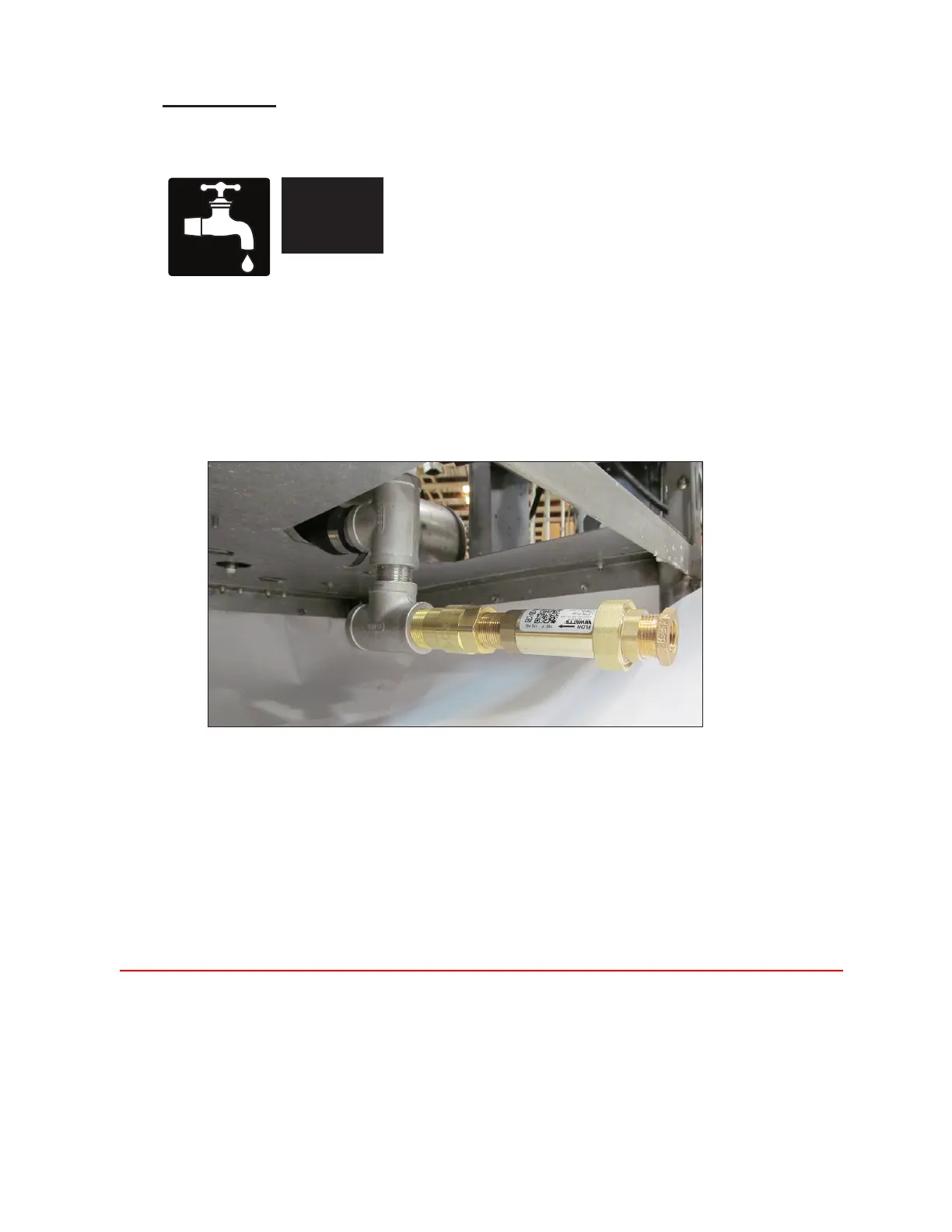

Fig. 8 - Mechanical drain water tempering valve

Installing the kit:

1. Installations should be done by a plumber in accordance with local plumbing codes.

2. Turn water and power o to the machine.

3. Remove panels.

4. Do not use sweat connections on any part of the kit to avoid damage to the tempering valve.

5. Connect the tempering valve to the drain line as close to the hot water discharge as possible.

6. Connect a 1/2" NPT cold water line to the tempering valve.

7. The installation of a ball shut-o valve for servicing (supplied by others) is highly recommended.

8. Maintain an indirect (air gap) connection to the oor drain, if the exit of the Tee is nished to

the oor drain.

9. Restore water supply and check for leaks.

10. Restore power and test the operation of the machine.

11. Replace panels.

12. Installation is complete.

Optional Mechanical Drain Water Tempering Valve Kit

Minimum/Maximum Incoming

Temperature

55-75º/13-24ºC

Minimum Incoming Supply

Flowing Pressure

46-50 PSI

Minimum/Maximum Operating

Flowing Pressure

16 PSI

• Water hardness of 3 Grains/US Gal. - 0.83 Imp. Gal - 5.3 mg/L or less.

7

Mechanical Water Valve

Requires a minimum 1/2" NPT cold water supply line.

Uses building water supply pressure.

Loading...

Loading...