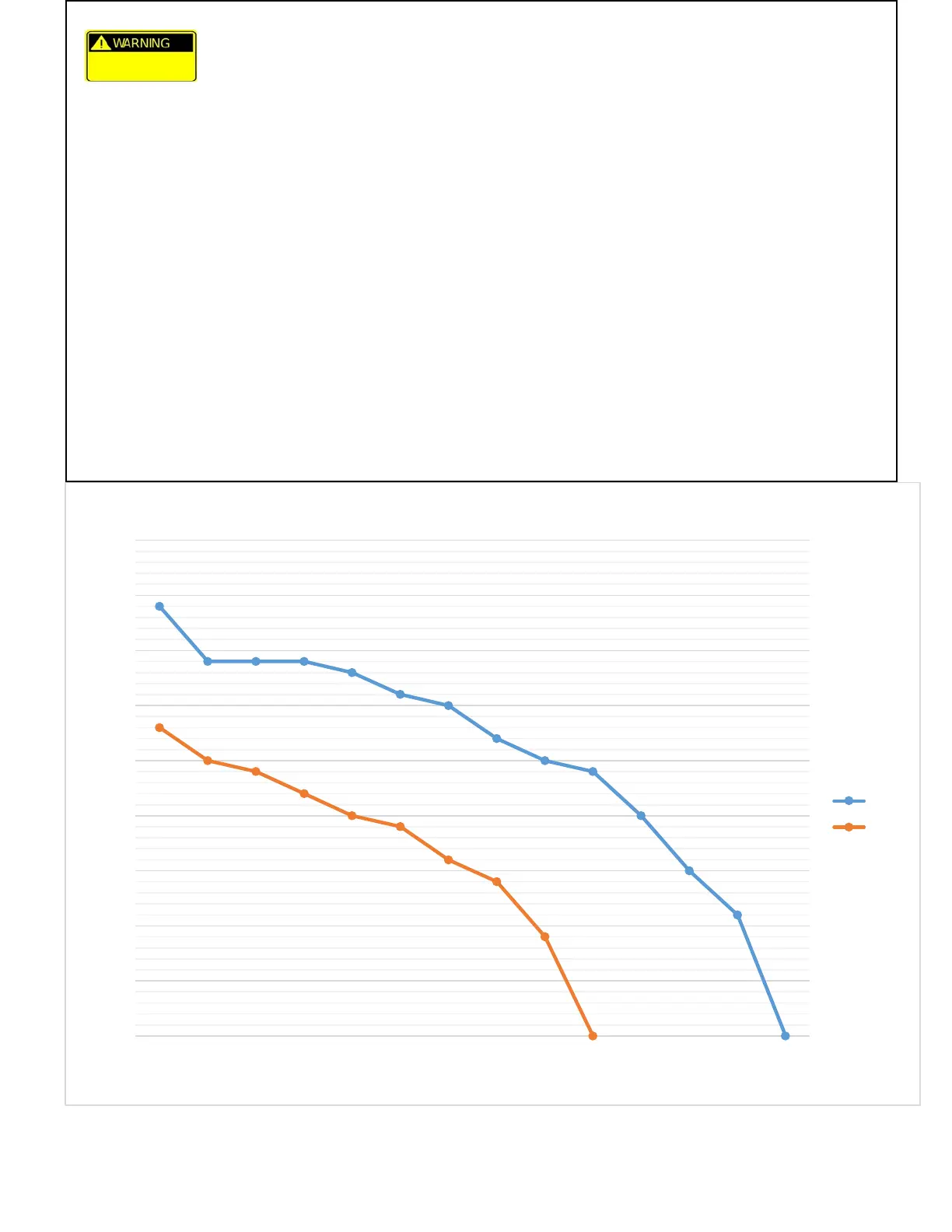

3

0

5

10

15

20

25

30

35

40

45

10 20 25 30 35 40 45 50 55 60 65 70 75 80

GPM

PSI

P-20 & P-35-2 FLow Curve

P-35-2

P-20

Important Electrical Grounding Information

B. Clamp or weld (or both if necessary) this bonding conductor

to

Hazardous voltage. Can shock, burn,

the grounding conductor to the equipment-grounding terminal,

or kill.To reduce the risk of electrical the grounding conductor on the pump housing, or an equipment

shock during pump operation, ground and bond the grounding lead. The equipment-grounding lead, when provided pump

and motor as follows: will be the conductor having green insulation; it may also have

A. To reduce risk of electrical shock from metal parts of the one or more yellow stripes.

assembly other than the pump, bond together all metal C. Ground the pump, motor and any metallic conduit that carries parts

accessible at the tank top (including metal discharge power cable conductors. Ground these back to the service by pipe, metal

tank top, and the like). Use a metal bonding connecting a copper conductor from the pump, motor, and

conductor at least as large as the power cable conductors conduit to the grounding screw provided within the

supplyrunning down the wall to the pump’s motor. connection box wiring compartment. This conductor must be at least as

large as the circuit conductors supplying the pump.

SAVE THESE INSTRUCTIONS

HAZARDOUS

VOLTAGE

Loading...

Loading...