11

Ozone Generator

The ozone generator houses the ozone reaction chamber(s), power supply and all electrical components directly related

to the production of ozone. Ozone is produced when the feed gas is exposed to a high voltage electrical current inside

the reaction chamber.

Air Preparation

The ClearWater Tech ozone system may be equipped with a heat regenerative desiccant air dryer. Corona discharge

ozone generators are much more effective, produce more ozone and require far less maintenance if an air preparation

unit is included. The air preparation system lowers the dew point of the feed gas. Moist feed gas (air) will cause nitric

acid to form inside the generator which decreases ozone production and if not removed, causes corrosion and eventual

failure of the generator’s internal components. The ability of the ozone generator to produce ozone is drastically reduced

as the dew point rises above -60°C.

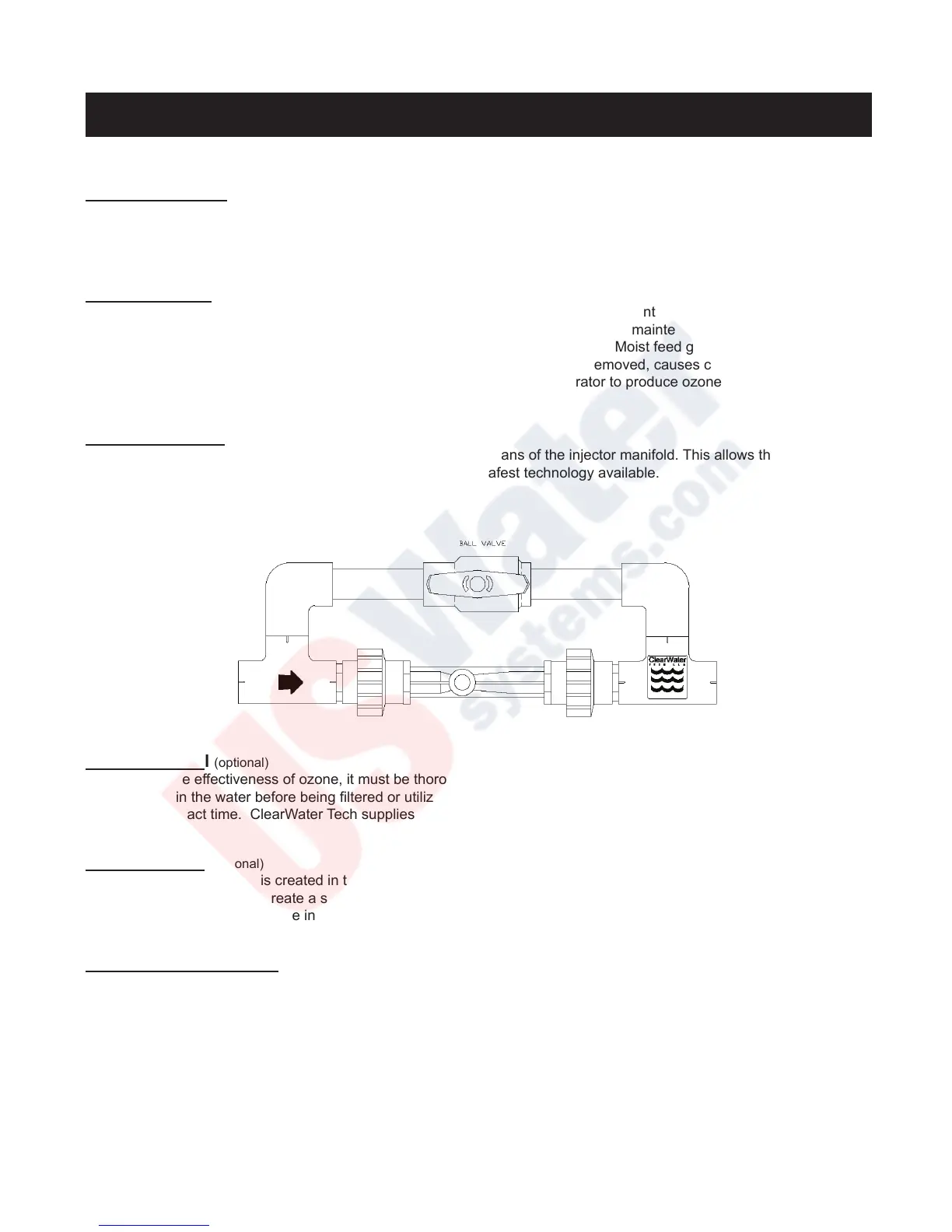

Injector Manifold

The ozone gas is injected into the ltered water return line by means of the injector manifold. This allows the ozone to be

injected into the water under a vacuum condition which is the safest technology available.

Contact Vessel (optional)

To maximize the effectiveness of ozone, it must be thoroughly mixed and have adequate time to react with the

contaminants in the water before being ltered or utilized. Contact vessels are designed to achieve this necessary

mixing and contact time. ClearWater Tech supplies several different types of contact vessels for a variety of applications.

Booster Pump (optional)

If excessive back pressure is created in the water line by lters, pressure tanks or other system parameters, a booster

pump may be necessary to create a sufcient pressure differential across the venturi. This booster pump is used in con-

junction with a side stream ozone injection loop.

Electrical Interlock Box (optional)

The electrical interlock box is a multi-function electrical enclosure. It houses the Motor Control Interlock (MCI), ORP

Interlock and the Vacuum Interlock. The enclosure also acts as the air preparation monitoring station, controlling the

amount of intake air and monitoring the vacuum.

Loading...

Loading...