(SAFETY INSTRUCTIONS)

- The blades have been balanced prior to delivery. Normal usage should not affect

the cutting edge. Any blade which receives an impact, becomes deformed or

marked must be replaced.

DO NOT TRY TO RECTIFY THE BLADE.

- Each time the blades are removed, the NYLSTOP nuts must be replaced with new

ones.

- The hydraulic components are adjusted and leaded in factory. Only a dealer

approved COLLARD is authorized to intervene on the adjustments.

- IMPORTANT: the conformity plate, bearing the equipment type and number, must

never be removed from the chassis.

- The operator or the driver should never leave the driver’s cab when the tractor is

moving.

- Nobody is authorized to be in the environment and / or on the trajectory of the

machine.

- Nobody must be installed on the machine.

- Never clean or release the accumulation of vegetation during the machine is

operating. For that, make sure that the engine of the tractor is stopped, and that

the machine is completely immobilized in a vertical position.

- Use, always, protective gloves for any operation.

- During movements on roads, it is imperative to stop the feeding of the electric

controller of the machine (emergency switch engaged); this in order to prevent any

start or any accidental movement of the machine.

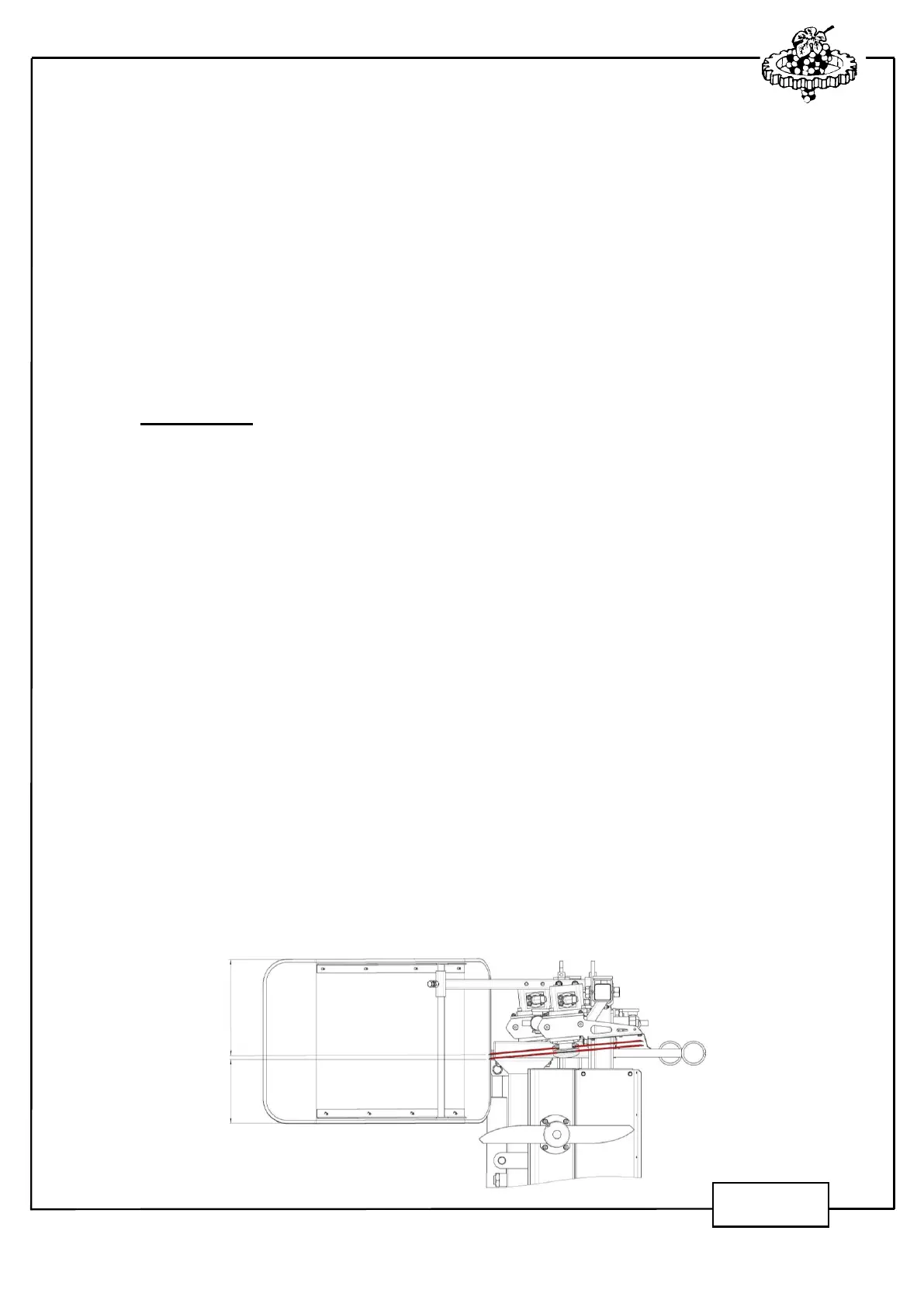

- Concerning the machines equipped with protective grates (machines adapted at

the rear mainly), always to take care that the blades of the horizontal cutting

elements are at least at 250 mm (10 inches) minimum inside the lower and upper

edges of the grates.

250 mm mini

(10 inches mini)

250 mm mini

(10 inches mini)

Loading...

Loading...