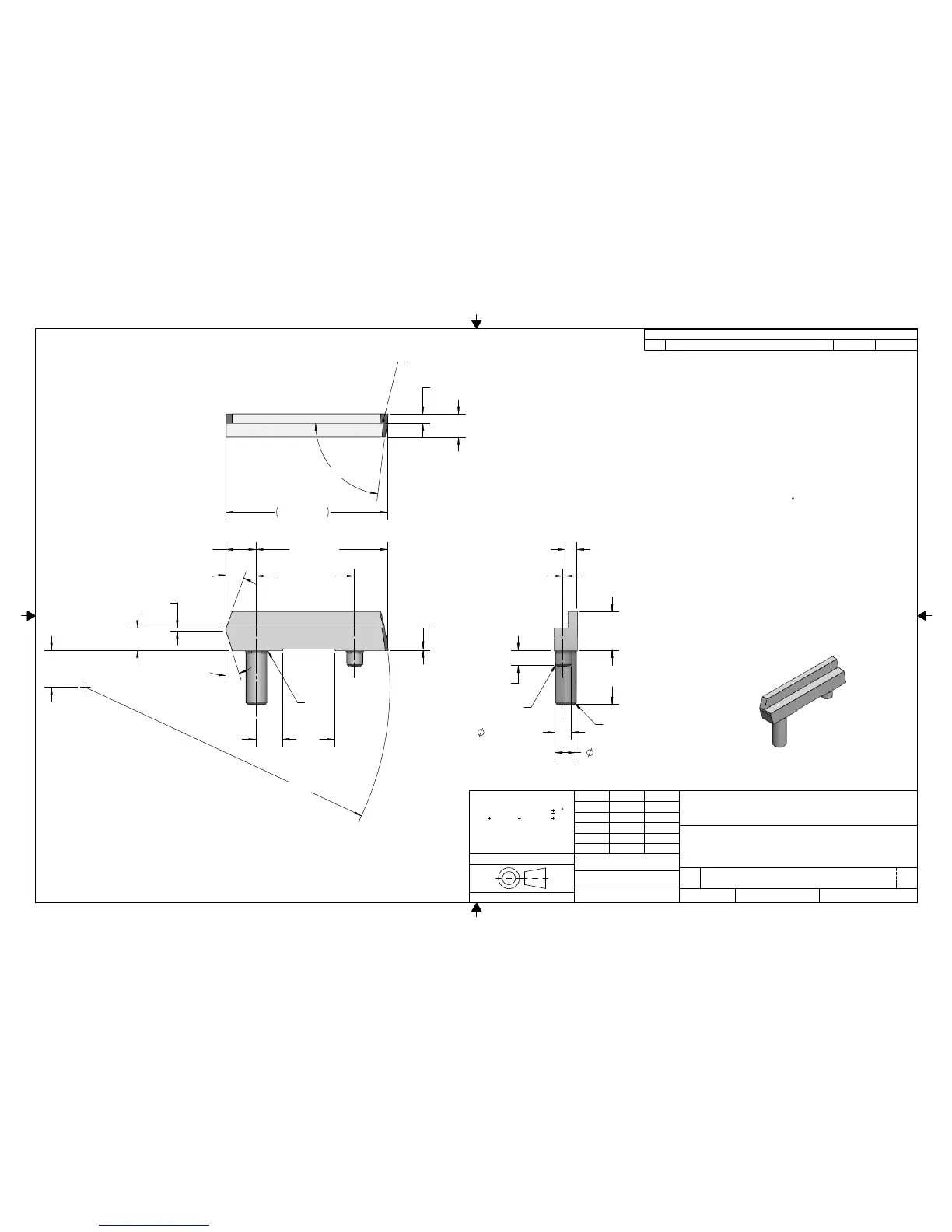

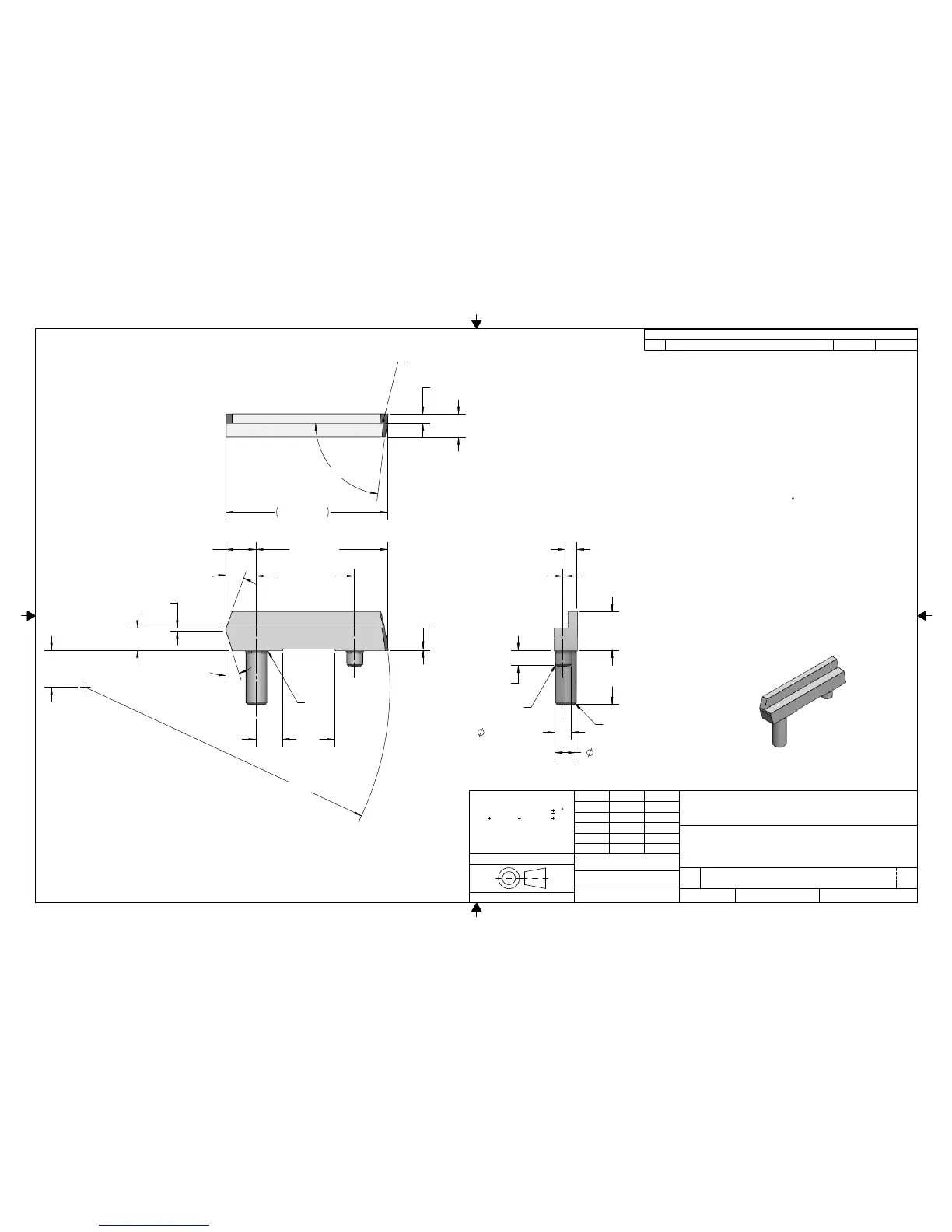

F; OIL QUENCH.

TEMPER 20 MINUTES AT HEAT TO

RH C 48-52. LEAVE LONG PIN SOFT

OR SOFTEN LONG PIN ONLY,

SUFFICIENT FOR DRILLING.

NOTES:

MATERIAL: STEEL, 1144, ASTM A311;1.

AUSTENITIC GRAIN SIZE 6 OR FINER.

HEAT TREATMENT: HEAT LARGE PIN 2.

END 1450 TO 1500

REVISION HISTORY

REV DESCRIPTION DATE APPRVD

6019024

HEAT TREAT

SEE NOTE 2

09/12/2010

R Benson

THIRD ANGLE PROJECTION

DIM & TOL IAW ASME Y14.5 - 1994.

―

ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF

ENGRG

DRAWN

MODELED

IS PROHIBITED.

SHEET 1 of 1

WEIGHT: 0.01 LBSCALE: 3:1

X

SEE NOTE 1

Benson Consulting, LLP

Benson Consulting, LLP.

1st MADE FOR: M1911-A1 REDUX

EJECTOR

B

08/22/2010 R Benson

DO NOT SCALE DRAWING

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE AND INTELLECTUAL PROPERTY OF

1-704-860-1202

Benson Consulting, LLP

REV

DWG NO

SIZE

TITLE

FINISH

MATERIAL

DATEBY

QA

MFG

PARA 5.3.1.2 OF MIL-STD-171

••

rhbenson@earthlink.net Gastonia, NC 28054

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN INCHES.

TOLERANCE: ANGULAR .5 ,

2 PL .01, 3 PL .005, 4 PL .0005,

SYMM & CONC: 1/2 FEATURE TOL.

FAB FINISH: 125 MICROINCH.

BRK/FIL SHARP COR .005 MAX.

POLISH AT ASSEMBLY

+

83°

-

.000

.004

-

+.000

.004

.056

.138

.964 MAX

.000

.220

.156 .312

.5850

2X R

-

MAX

17.5°

.010

+

.135

-

20°

R

.005

1.813

-

.18

+.000

.005

++

.01

.000

±.0015

.00

.015

.784

.020

-

.010 PERMITTED

MISMATCH

- .003

.013±.001

X

.067

.01

.233

- .005

.000

.0965

.0015

+.0000

+

-

.00+

.01-

.00+

.01-

.32

±5°45°

-

.01

.00-

.02+

.00

X ±5°

.09

45°

.02+

.000+

.1245

- .0015

+.0000

Loading...

Loading...