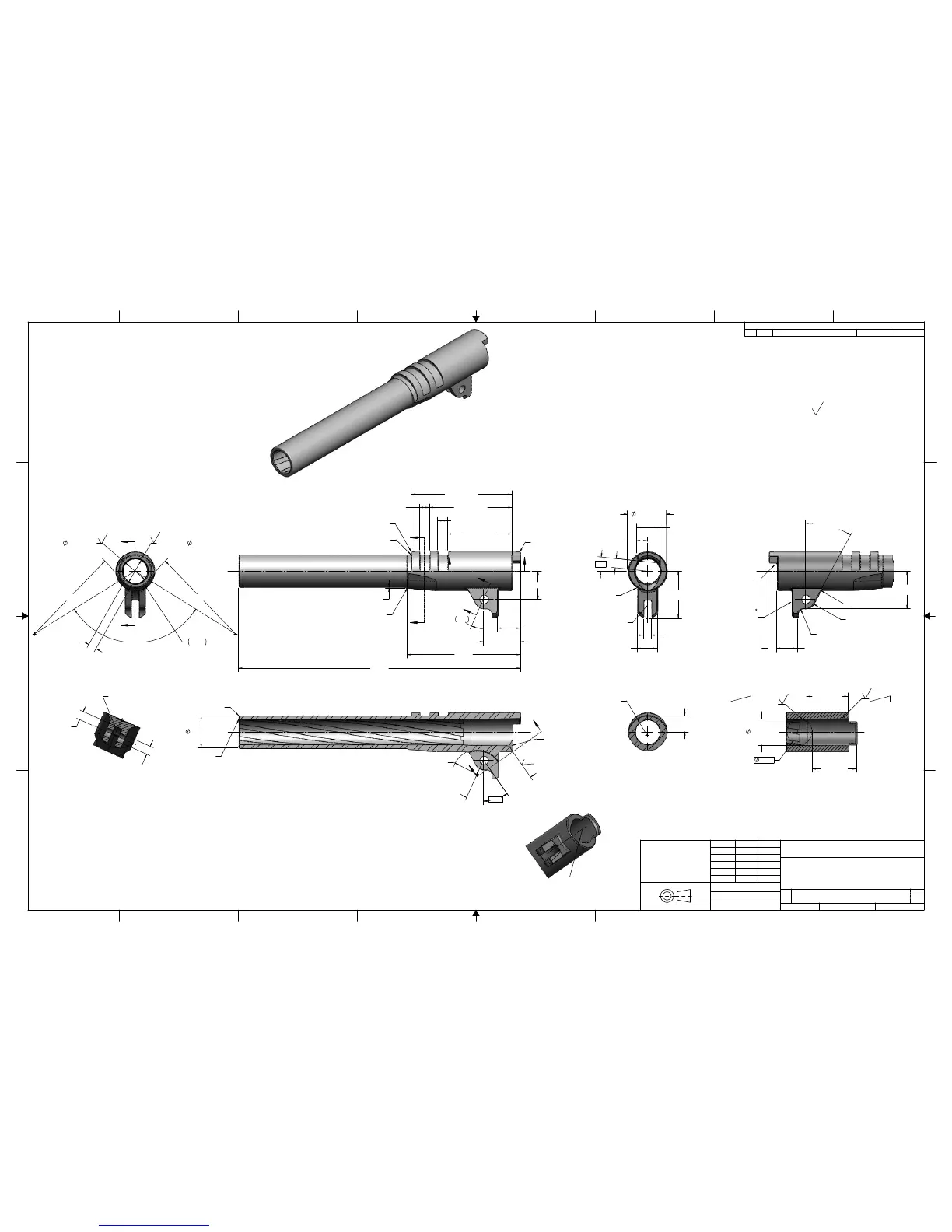

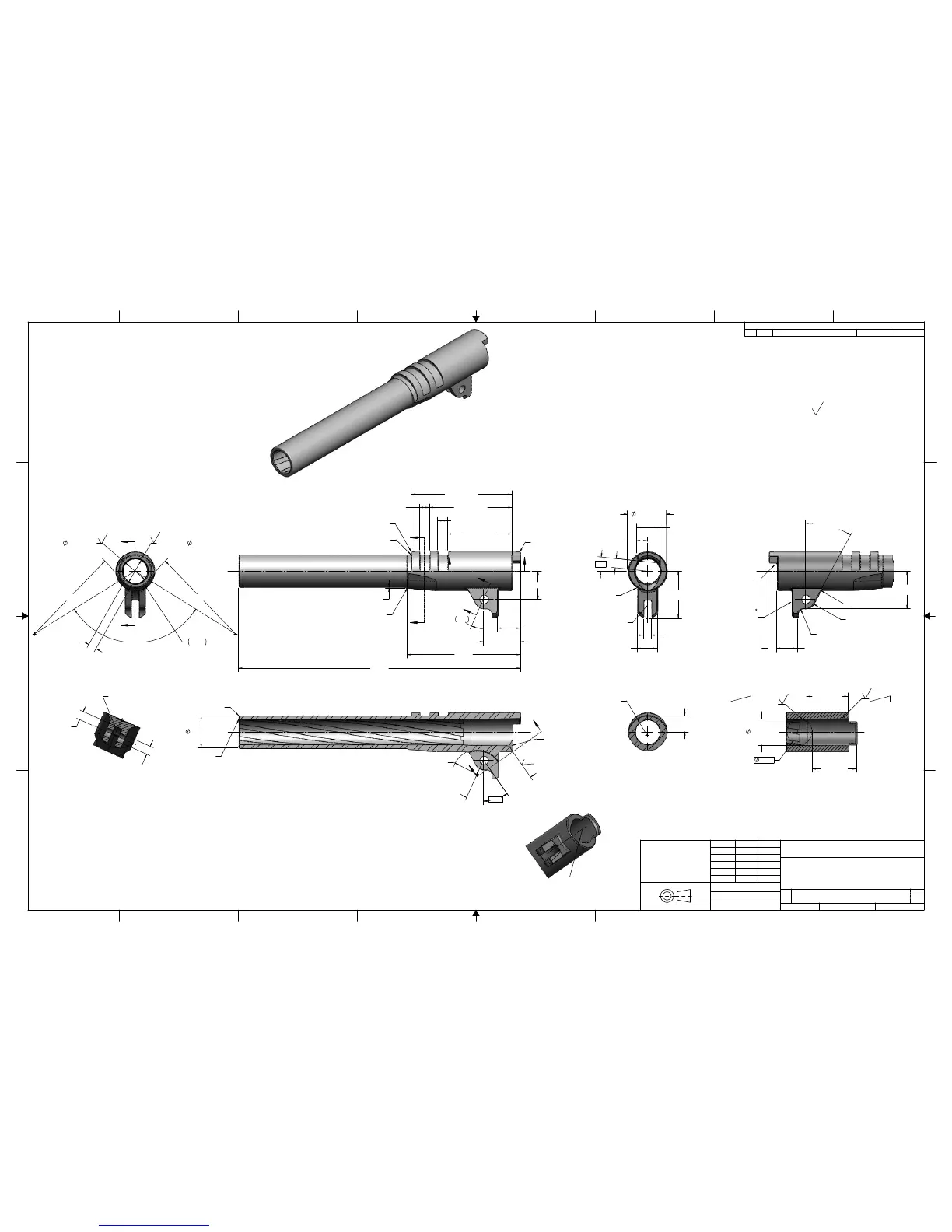

116°±2°

6°

.165

.84

-.01

+.00

R.10

-.01

+.00

R.17

-.01

+.00

.670

-.005

+.000

.369

-.005

+.000

24°

.015

-.010

+.000

.450

.790

-.000

+.020

.290

-.005

+.000

35°

24°

RIFLING SHALL CONSIST OF 6 EQ SP GROOVES

FINISH: THIN DENSE CHROME COATING (ARMOLOY

4.

TDC) IAW SAE AMS2438, AFTER SURFACE POLISHING.

ALL DIMENSIONS APPLY AFTER HEAT TREATMENT.

HAVING A CCW HELIX

5.

OF 1 TURN IN 16 INCHES

HEAT TREATMENT: AUSTEMPER TO RH C 53 TO 56.5.

NOTES:

MACHINED FINISH

63

EXCEPT AS NOTED.1.

DIAMETERS AT MUZZLE SHALL NOT BE GREATER2.

THAN THOSE AT BREECH.

MATERIAL: STEEL, 4150, ASTM A-108; AUSTENITIC3.

GRAIN SIZE 5 OR FINER.

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPRVD

1-704-860-1202

IS PROHIBITED.

HEAT TREAT

A

B

C

D D

C

B

A

8

7 6 5 4 3 2 1

8

7 6 5

SYMM & CONC: 1/2 FEATURE TOL.

SEE NOTE 5

1st MADE FOR:

―

BARREL

ENGRG

09/15/2010 R Benson

07/29/2010 R Benson

SHEET 1 of 1 WEIGHT: 0.21 LBSCALE: 2:1

X 7791193 D

M1911-A1 REDUX

Gastonia, NC 28054

Benson Consulting, LLP

4 3

1

5 - 1994.

THIRD ANGLE PROJECTION

DO NOT SCALE DRAWING

MODELED

DRAWN

MFG

QA

BY DATE

MATERIAL

FINISH

SIZE REV

FAB FINISH: 125 MICROINCHES.

BRK/FIL SHARP COR .005 MAX.

DIM & TOL IAW ASME Y14.

SEE NOTE 3

• rhbenson@earthlink.net

•

DWG NO.

TITLE

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN INCHES.

TOLERANCES: ANGULAR

±

.5

°

,

2 PL ±.01, 3 PL ±.005, 4 PL ±.0005,

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE AND INTELLECTUAL PROPERTY OF

Benson Consulting, LLP

.

ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF

Benson Consulting, LLP

SEE NOTE 4

- .004

+.000

.696

.188

- .005

+.000

- .005

+.000

R.025

.415

.005+

.000-

.138

.000+

.004-

.362

R.22

- .01

+.00

R.06

BREAK EDGE

.015+.010 X 45

BOTH SIDES

.005+

±1.0°

.000-

28.5°

.149

2X TRUE R.025

- .010

+.000

32

32

.450

+.002

GROOVE:

.000

1.81

.000

1.81

+

GROOVE

.002

-

TRUE R

LAND .442

TRUE R

-

6X .147

- .000

+.013

R.31

A

A

- .010

+.000

±.002

R.025

.4065

6X R.010

- .005

+.000

- .000

+.010

45°3X .015

.000+

.006-

1.152

.004+

.000-

.176

.000+

-

.176

.000+

.006-

1.476

.004

1.801

.0040

+

.000

±.002

.659

.006-

2.027

5.031

+

.0000-

.503

X

5X .005

- .000

+.010

45° X

D

D

B

B

C

C

SECTION G-G

R

.232

- .000

+.003

SECTION D-D

32

BASICBASIC

.090 : 1 .008 : 1

32

.474

- .000

+.002

.743

- .000

+.003

SECTION C-C

R.348

- .005

+.000

SECTION B-B

.001+

.000

.005+

.160

- .000

.154

-

2X R.015

- .010

+.000

BEFORE COATING

SECTION A-A

POLISH RAMP

1

6

+

.438R

.512

- .005

X

.000

.062

.000

- .000

+

45°

.580

- .002

+

.02

R.02

E

E

Loading...

Loading...