1571/128D ALIGNMENT/REPAIR TEST

VERSION 1.2.1

+ — — — — — — — — — — — — -------------— — — — — — — — — —

-----------

— — — — — — — — — — — — — — -----------— — — —

----

— — — — — — — — +

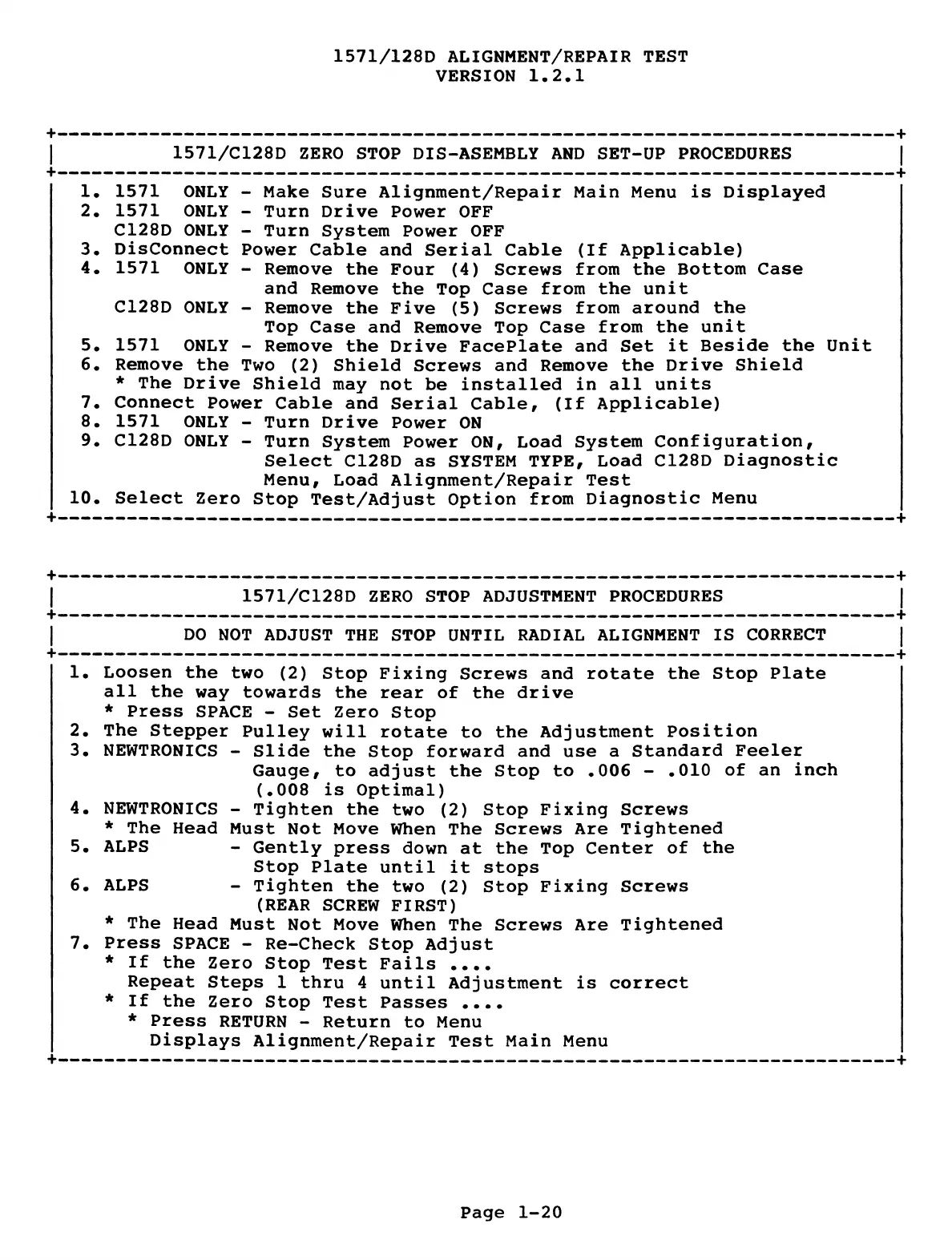

| 1571/C128D ZERO STOP DIS-ASEMBLY AND SET-UP PROCEDURES |

+-------------------------------------------------------------------------------+

1. 1571 ONLY - Make Sure Alignment/Repair Main Menu is Displayed

2. 1571 ONLY - Turn Drive Power OFF

C128D ONLY - Turn System Power OFF

3. Disconnect Power Cable and Serial Cable (If Applicable)

4. 1571 ONLY - Remove the Four (4) Screws from the Bottom Case

and Remove the Top Case from the unit

C128D ONLY - Remove the Five (5) Screws from around the

Top Case and Remove Top Case from the unit

5. 1571 ONLY - Remove the Drive FacePlate and Set it Beside the Unit

6. Remove the Two (2) Shield Screws and Remove the Drive Shield

* The Drive Shield may not be installed in all units

7. Connect Power Cable and Serial Cable, (If Applicable)

8. 1571 ONLY - Turn Drive Power ON

9. C128D ONLY - Turn System Power ON, Load System Configuration,

Select C128D as SYSTEM TYPE, Load C128D Diagnostic

Menu, Load Alignment/Repair Test

10.

-

Select Zero Stop Test/Adjust Option from Diagnostic Menu

-

+

+--------------------------------------------------------------------------------------------------------------------+

| 1571/C128D ZERO STOP ADJUSTMENT PROCEDURES |

+--------------------------------------------------------------------------------------------------------------------+

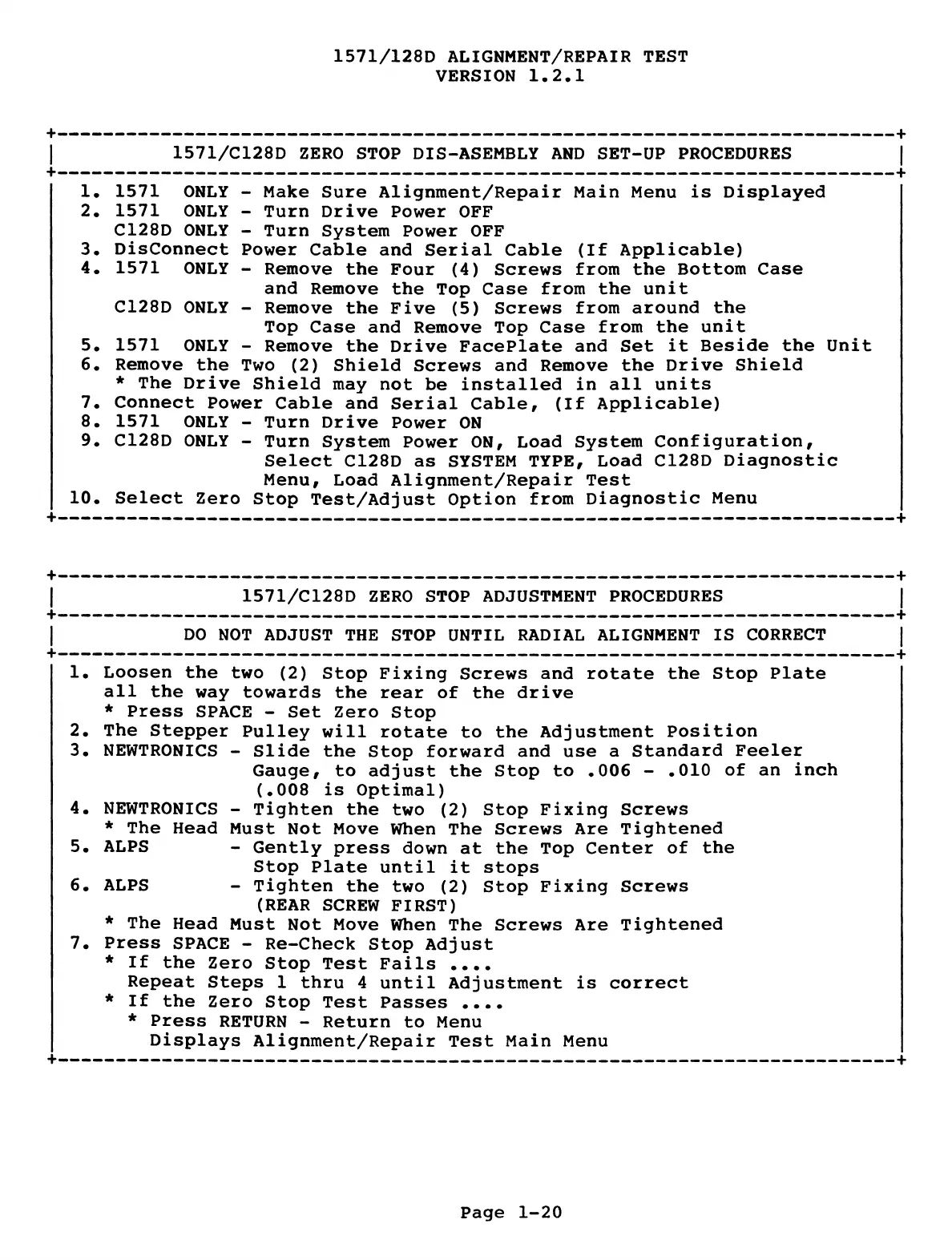

| DO NOT ADJUST THE STOP UNTIL RADIAL ALIGNMENT IS CORRECT |

+-------------------------------------------------------------------------------+

1. Loosen the two (2) Stop Fixing Screws and rotate the Stop Plate

all the way towards the rear of the drive

* Press SPACE - Set Zero Stop

2. The Stepper Pulley will rotate to the Adjustment Position

3. NEWTRONICS - Slide the Stop forward and use a Standard Feeler

Gauge, to adjust the Stop to .006 - .010 of an inch

(.008 is Optimal)

4. NEWTRONICS - Tighten the two (2) Stop Fixing Screws

* The Head Must Not Move When The Screws Are Tightened

5. ALPS - Gently press down at the Top Center of the

Stop Plate until it stops

6. ALPS - Tighten the two (2) Stop Fixing Screws

(REAR SCREW FIRST)

* The Head Must Not Move When The Screws Are Tightened

7. Press SPACE - Re-Check Stop Adjust

* If the Zero Stop Test Fails ....

Repeat Steps 1 thru 4 until Adjustment is correct

* If the Zero Stop Test Passes ....

* Press RETURN - Return to Menu

Displays Alignment/Repair Test Main Menu

+-------------------------------------------------------------------------------+

Page 1-20

Loading...

Loading...