Troubleshooting 7

October 2013 GB 43 /80

7 TROUBLESHOOTING

If a fault or warning (alarm) occurs, this is output to

the display as a message. Moreover LEDs, a sym-

bol in the status/message area and the symbol on

the "Fault History" tab all flash.

Alarm acknowledgement

After the cause of the alarm has been cleared, the

alarm must be reset in the controller.

1 Clear the cause of the alarm.

2

Tap the <Fault History> tab.

–

The menu "Fault History" appears.

3

Tap the <Reset> button.

✓ The alarm is reset.

– The flashing alarm symbol disappears.

–

The symbol on theFault History> tab stops

flashing.

Alarms that are still uncleared cannot be reset.

The alarm symbol and the symbol on the <Fault

History> tab continue to flash.

7.1 Troubleshooting check list

Loose connections or plugs, a faulty power supply

or failure to observe information/instructions can

give rise to a whole series of faults.

The following points must be observed to avoid

faults.

The supply voltage must be within the permissi-

ble limits.

The control transformer must be set to the local

rated voltage (see wiring diagram diagram).

The control cabinet temperature must not ex-

ceed 50 °C.

Retrospectively installed remote controls (po-

tential-free contacts) must not be more than 20

metres away from the terminal strip.

If necessary, coupling relays must be fitted in

the switch cabinet.

Before commissioning and after performing

maintenance work, make sure that all con-

nection screws are tight and that all plugs are

firmly connected.

Power supply cables must be of adequate

cross-section. When rating the cable(s), there-

fore, pay attention to the cable-laying method,

line length and cable temperatures to be ex-

pected.

When retro-fitting switchgear, the control-power

transformers must not, under any circum-

stances, be "tapped" as they could be over-

loaded.

Do not connect additional switchgear or mea-

suring equipment without the approval of Gard-

ner Denver.

Do not route measuring sensors outside the

compressor.

Only use original Gardner Denver spare parts.

In the event of technical queries, have the fol-

lowing information to hand:

– System type / factory number

– Re-order ref.

– Circuit diagram, drawing no. and ID no.

– Information about operating conditions

– Information on any accessories you have

retrospectively installed (remote controls,

etc.)

– Information about other retrospective

changes or add-ons

– The fault number and precise description of

the fault that has occurred

7.2 How the Fault and Warning

Codes are Structured

Fault codes consist of a letter, a number, and a

brief description of the error that has occurred

(event).

Letters

The letter "A" indicates warnings.

The letters "E" and "F" indicate faults.

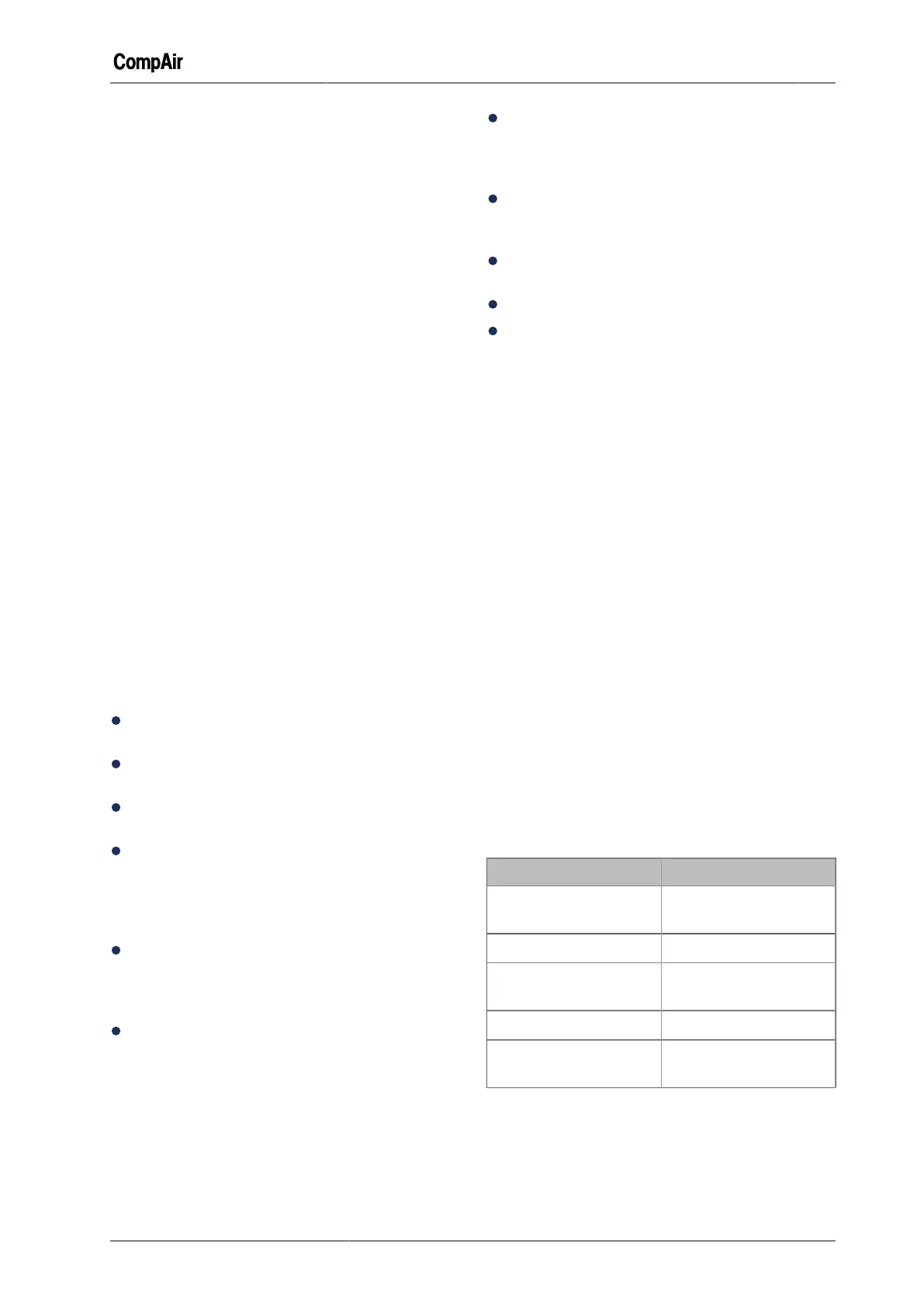

Number Range

Number range refers To

000 ... 399 Frequency converter

(RS-Compressors)

400 ... 495 Compressor

500 ... 531 Frequency converter

(RS-Compressors)

600 ... 695 Compressor

700 ... 731 Frequency converter

(RS-Compressors)

Chart 7-1: Number ranges for fault and warning codes

Loading...

Loading...