7 Troubleshooting

50 / 80 GB October 2013

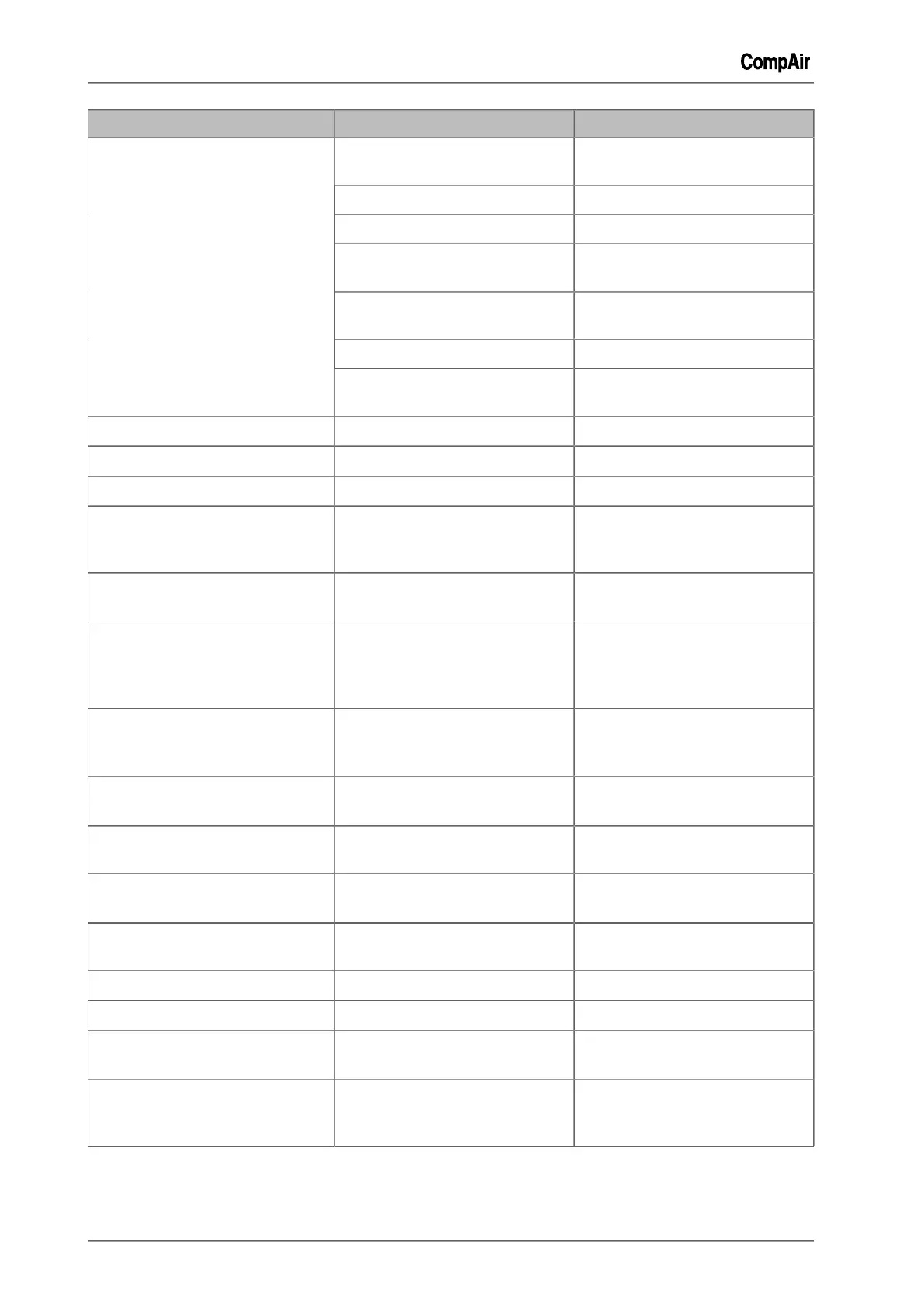

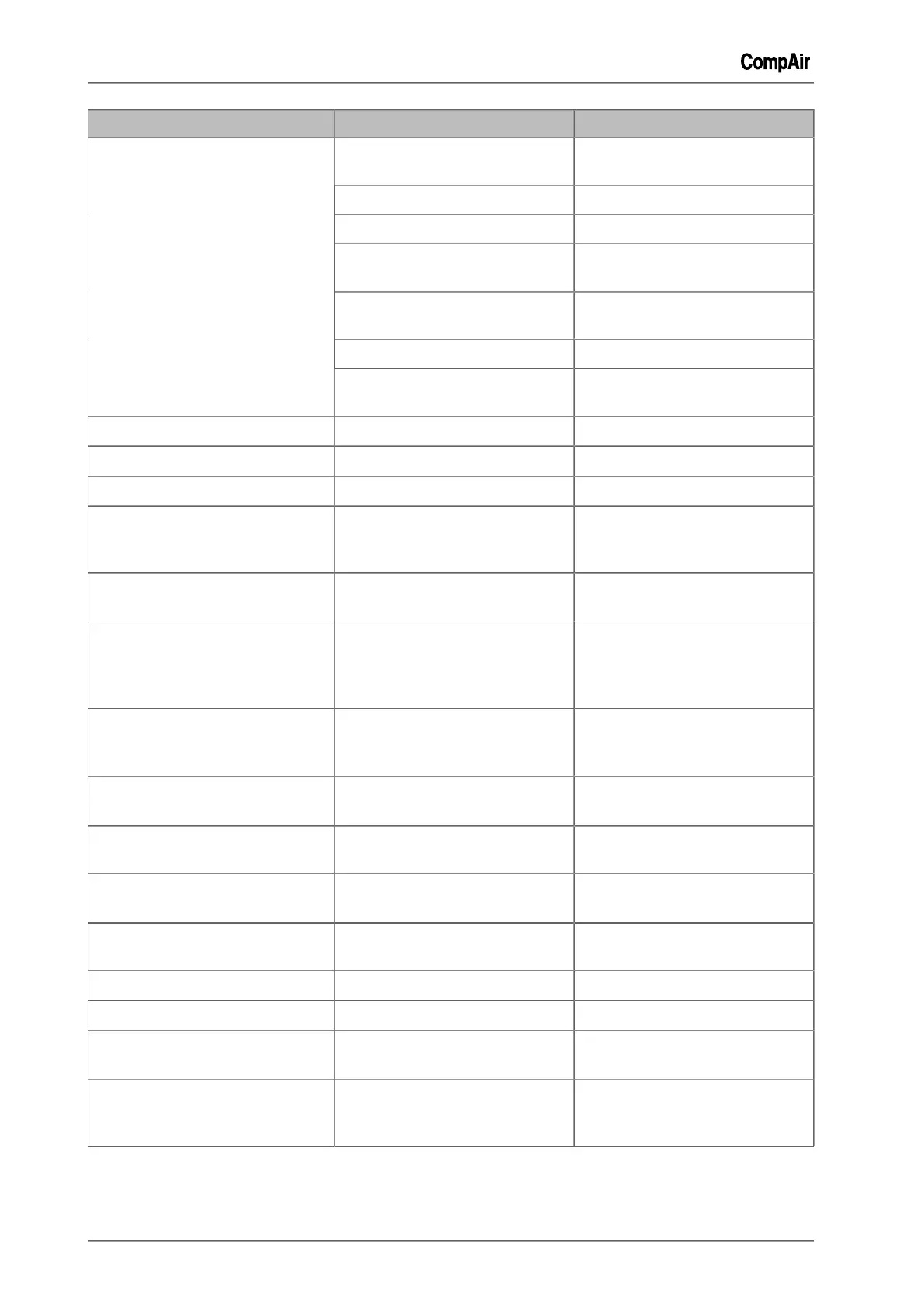

Display Possible Cause Remedy

Final compression temperature

exceeded.

1)

Find cause.

Intake temperature too high. Improve.

Inadequate cooling. Improve.

Unit being operated with enclo-

sure open.

Close the enclosure.

Oil injection volume/temperature

too low/high.

Check, find cause.

Incorrect oil grade/viscosity. Check, if necessary replace oil.

A602:Compressor Disch. Temp.

R2 temperature sensor defective

(indication too high).

Check, renew if necessary.

A603:

Not used / reserved

A604:

Not used / reserved

A605:

Not used / reserved

A906:

Line Pressure high

For more information, see "Con-

figuration / Advanced Settings /

Remote Load and Off-load"

A607:

Controller Battery empty

Battery empty Renew battery: Gardner Denver

Part no. 100016235

A608:

Dryer

(compressor without speed con-

trol)

Fault in the integral or external

dryer.

3)

See Chapter on the integrated

dryer in the compressor operating

instructions.

A608:

Dryer

(Compressor with speed control)

Fault from external dryer.

3)

Check, find cause.

A609:

Condensate Drain

Connected condensate drain

valves (Bekomat) defective

3)

Check, find cause.

A610:

Not used / reserved Check, renew fine separator if

necessary.

A611:

Air Filter

Differential pressure of the air fil-

ter too high

3)

Check, change air filter if neces-

sary.

A612:

Not used / reserved Check, renew oil filter if neces-

sary.

A613:

Not used / reserved Check, replace oil if necessary.

A614:

Not used / reserved Check, find cause.

A615:

External Warning

Warning due to external device.

4)

Check, find cause.

A616:

Motor lubrication system

A fault has occurred in the motor

greasing system or the LC unit is

running low.

3)

See Chapter on Motor greasing

system in the operating instruc-

tions for the compressor system.

Chart 7-5: Warnings triggered from the compressor (A600 - A695)

Loading...

Loading...