Base Load Sequencing (BLS) 10

October 2013 GB 73 /80

Digital output "Remote load"

Do not use this output to switch the compressor on

and off.

This output switches the compressor on load. This

remote load signal should be active when the "Re-

mote load enabled" output is sent to the compres-

sor controller.

Digital output "Remote half-load"

This output is not used for this application.

Connection allocation and connection

examples

Connection allocation

Port Function

6 COM

7 110...230 V UC

8

Digital input "Oper-

ating"

24...48 V UC

9 COM

10 110...230 V UC

11

Digital input "Motor"

24...48 V UC

12 COM

13 110...230 V UC

14

Digital input "On-

Load"

24...48 V UC

16 (~) (+)

17

Power supply

110...230 V AC/DC

(±)10%

(~) (-)

21 COM

22 NC

23

Digital output

"Remote load

enabled"

NO

26 COM

27 NC

28

Digital output

"Remote load"

NO

31 COM

32 NC

33

Digital output

"Remote half-load"

NO

Chart 10-11: Connection allocation

Compressor Status Messages

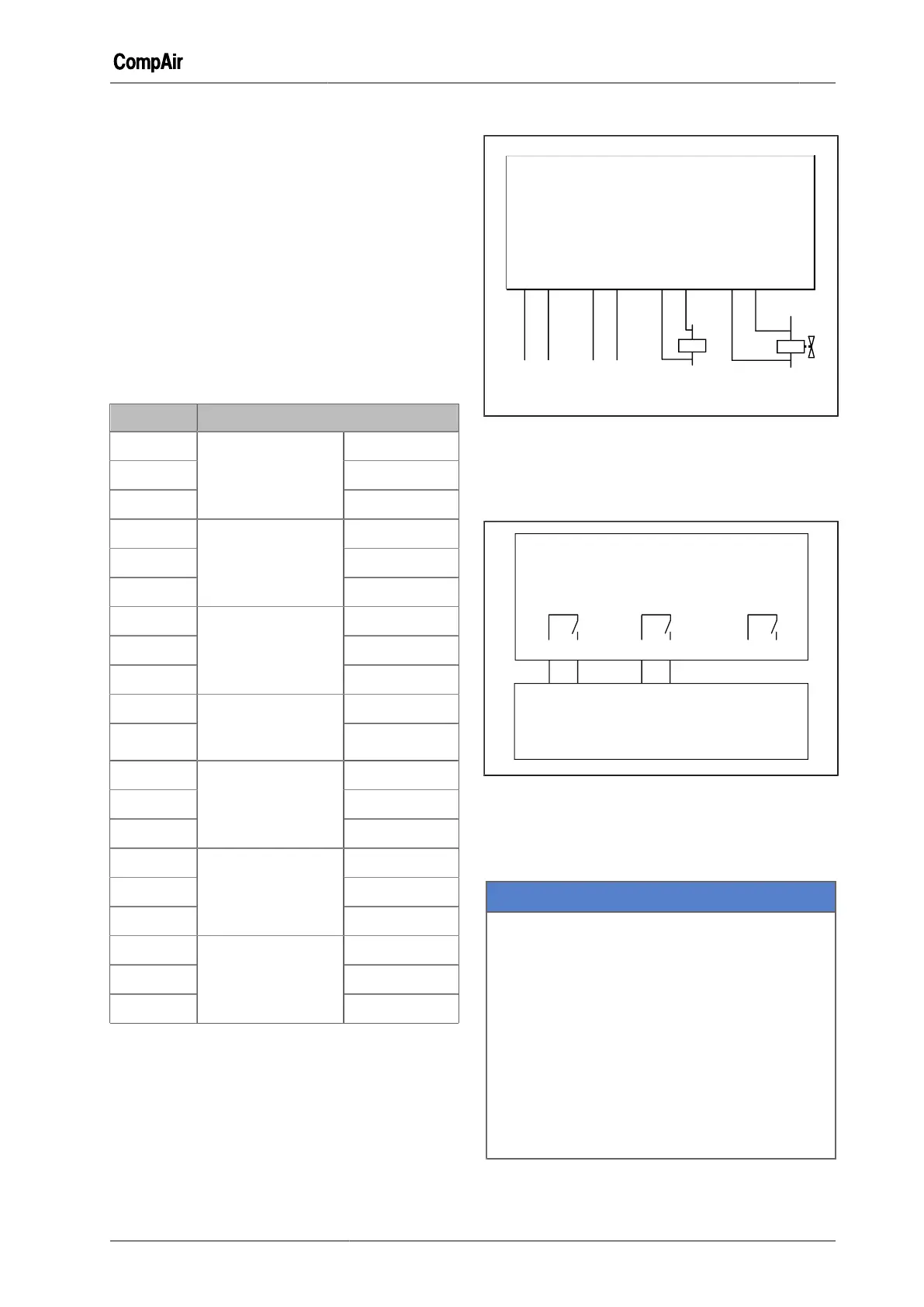

Fig. 10-18: Connections for status messages

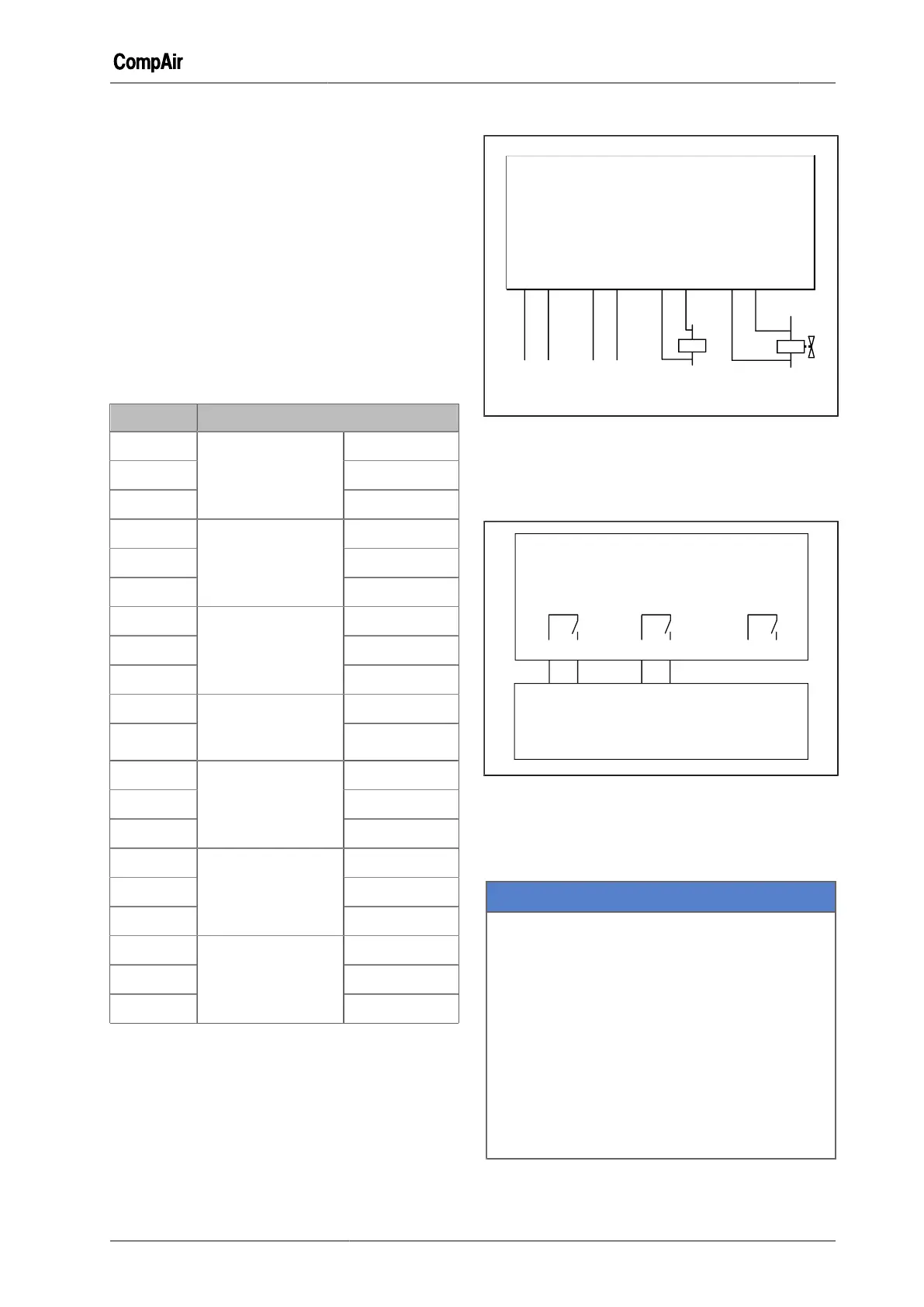

Controlling a compressor with line pressure

sensor and electronic compressor controller

(example)

Electronic compressor controller

Fig. 10-19: Line pressure sensor and electronic com-

pressor controller

Controlling a compressor with line pressure

switch (example)

NOTICE

Material damage

When a compressor module (STD) is installed,

the compressor's pressure switch can, under

certain circumstances, no longer provide over-

pressure protection.

➯

For compressors that are not equipped with

independent over-pressure detection, we

recommend that a pressure switch be incor-

porated in the compressor fault circuit(s) to

ensure that any local over-pressure condi-

tion will stop the compressor independently

from the DELCOS XL Master.

Loading...

Loading...