31COMPRAG Screw air compressor F-Series

5. Maintenance

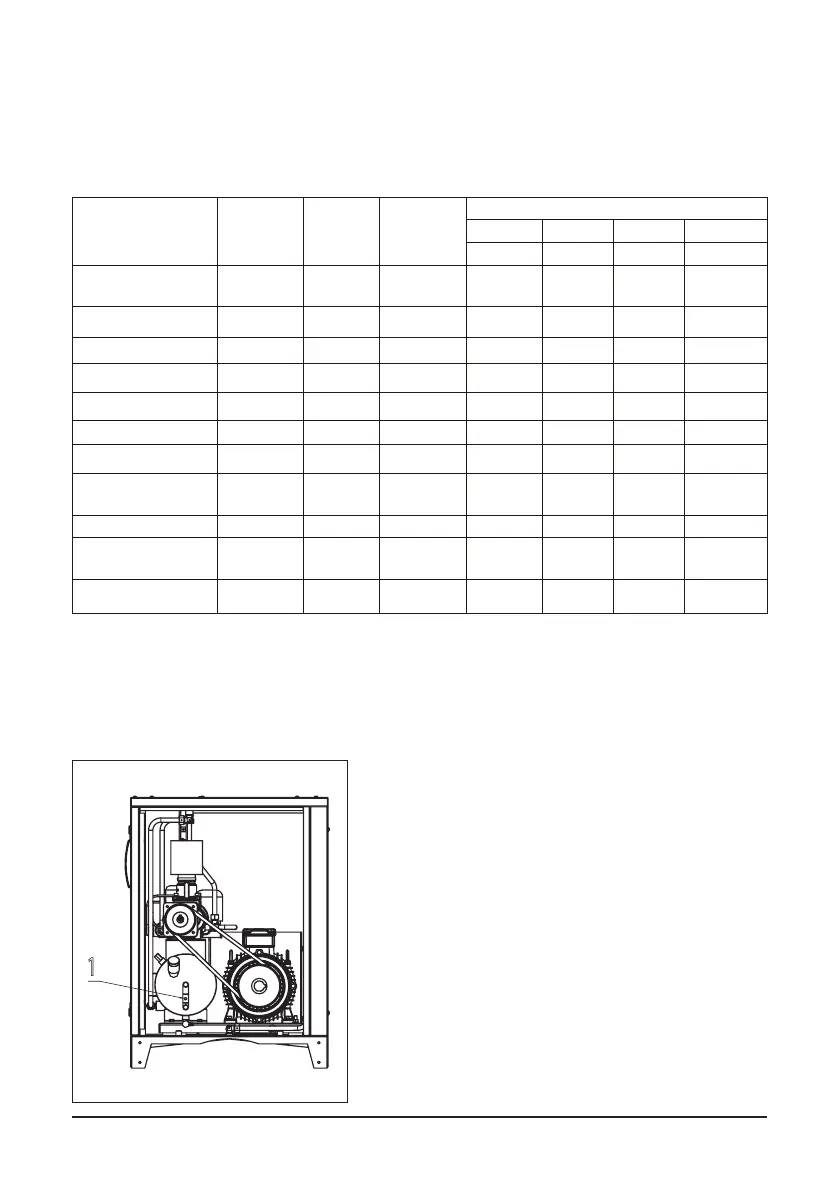

5.1 Maintenance schedule

Maintenance schedule

Daily Monthly Yearly

Interval in work hours

M-1 M-2 M-3 M-2

500 2000 4000 6000

Oil level Check/

Rell

Compressor oil Replace Replace Replace Replace

Air lter Cleaning Replace Replace Replace

Oil lter Replace Replace Replace Replace

Ait-Oil Separator Replace

Drive belt Check

Heat exchanger Cleaning

Bearings of electric

motor

Lubricate

Intake valve Check

Minimum pressure

valve

Check

Safety valve Check

Beyond 6000 working hours, compressor maintenance consists in alternating M-2 and M-3

every 2000 hours of running time. Performance of daily, weekly, monthly and annual ser-

vicing does not annul the need for maintenance in terms of operating hours.

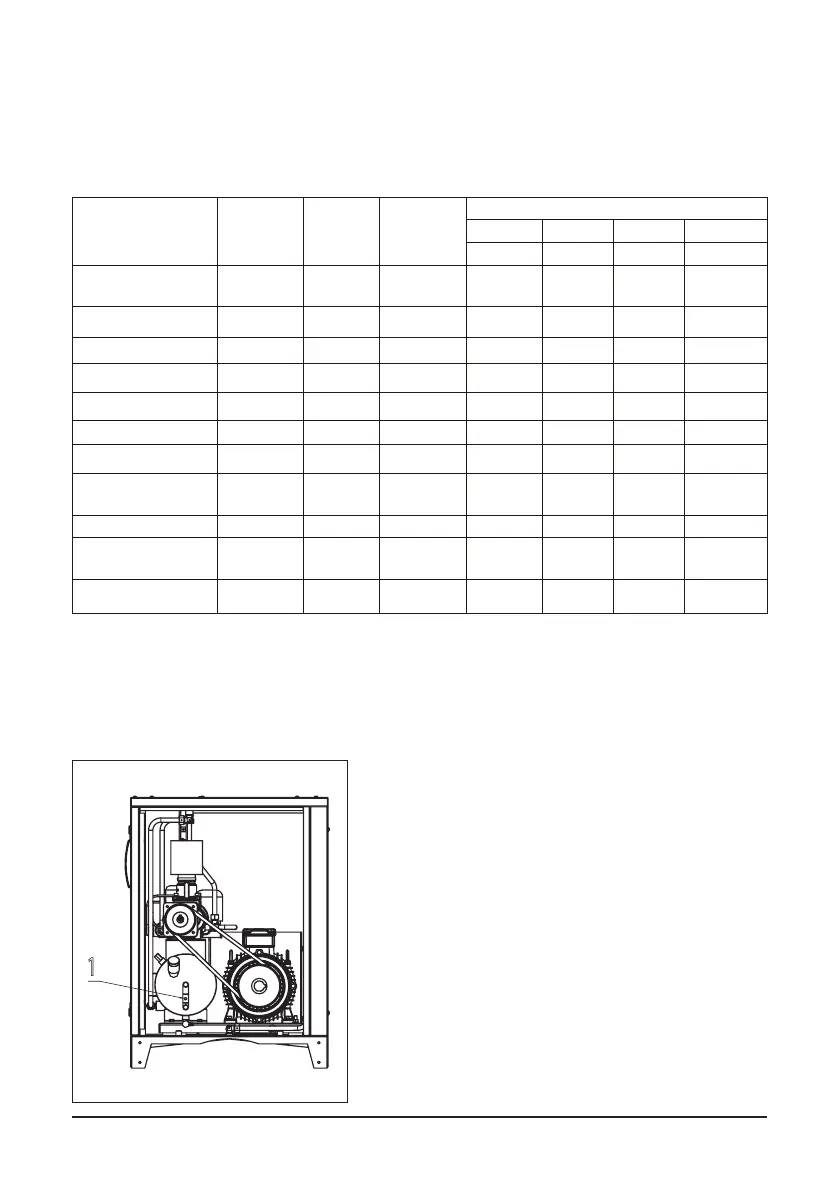

5.2 Checking oil level

Fig. 5.2 Checking oil level

Check oil level on a daily basis. The oil level in the

compressor should be checked visually with the oil le-

vel glass (1) when the compressor has stopped. The

surface of the oil must always be visible in the sight

glass. If no oil is visible in the sight glass, the oil level

is low and needs to be topped up.

1

Loading...

Loading...