Specifications

5-7

For example: If your cryostat has a boil off rate of 9 liters/day and the PT410 Cold Head

is capable of recondensing 11 liter/day in “your installation,” heat must be added by the

pressure controller to reduce the effective recondensing rate of the PT410 Cold Head. If

this does not happen effectively, the pressure inside the cryostat will drop below 1

+

Atmosphere, which Cryomech does not recommend.

If the pressure inside the system drops to below 1 Atm., air might enter the system and

solidify on the Cold Head heat exchangers. This will reduce the efficiency of the Helium

Reliquefier and possibly block the flow of liquid helium through the return line.

The Helium Reliquefier has been designed to operate with cryostats that have already

been filled with liquid helium. But for small cryostats, the Helium Reliquefier can cool

down the cryostat from room temperature and fill it with liquid helium. For this

application, a helium gas supply from a gas cylinder and a pressure regulator will be

required.

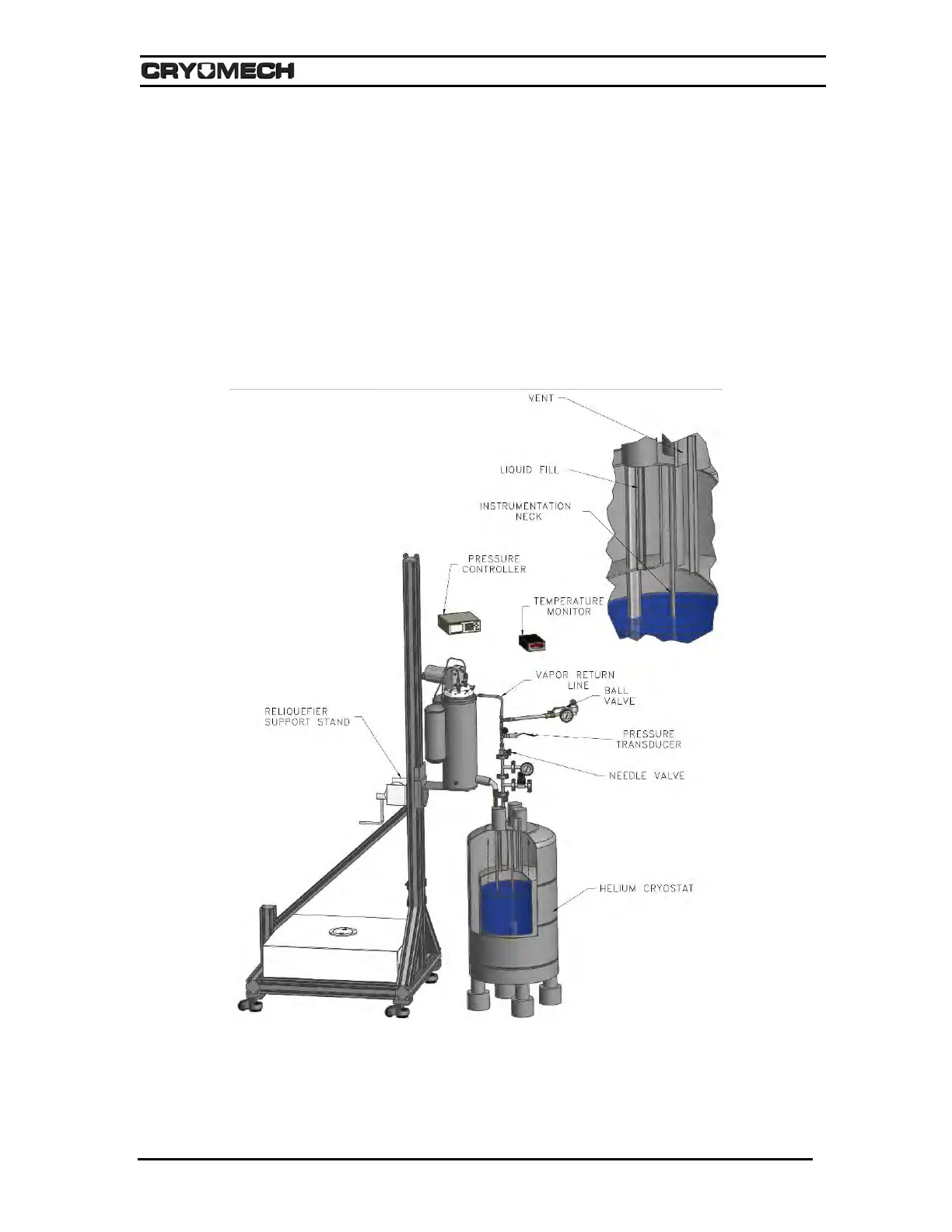

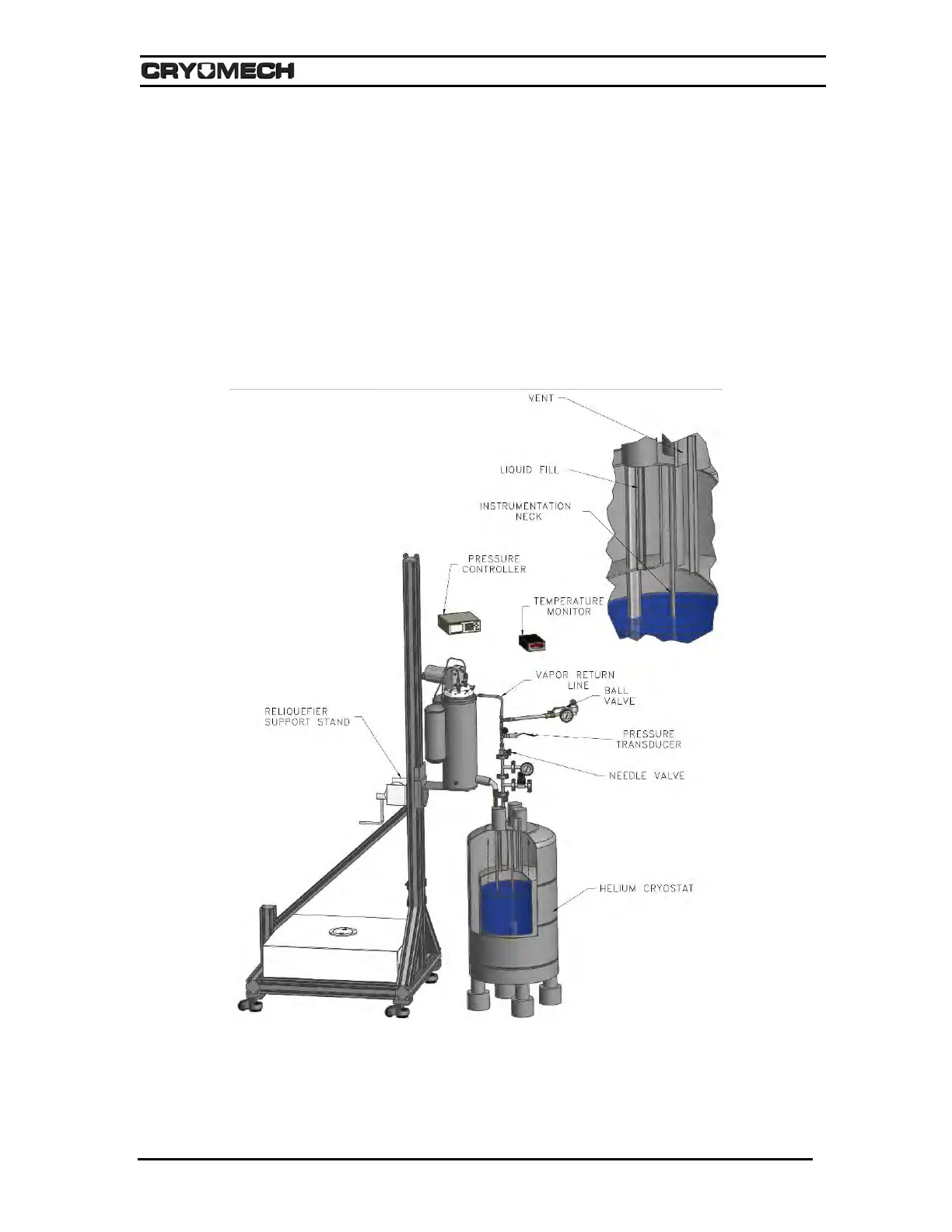

Figure 5-4: Helium Reliquefier to cryostat installation

Loading...

Loading...