Monday, August 10 200 9 2/2 TD20090810 – V03

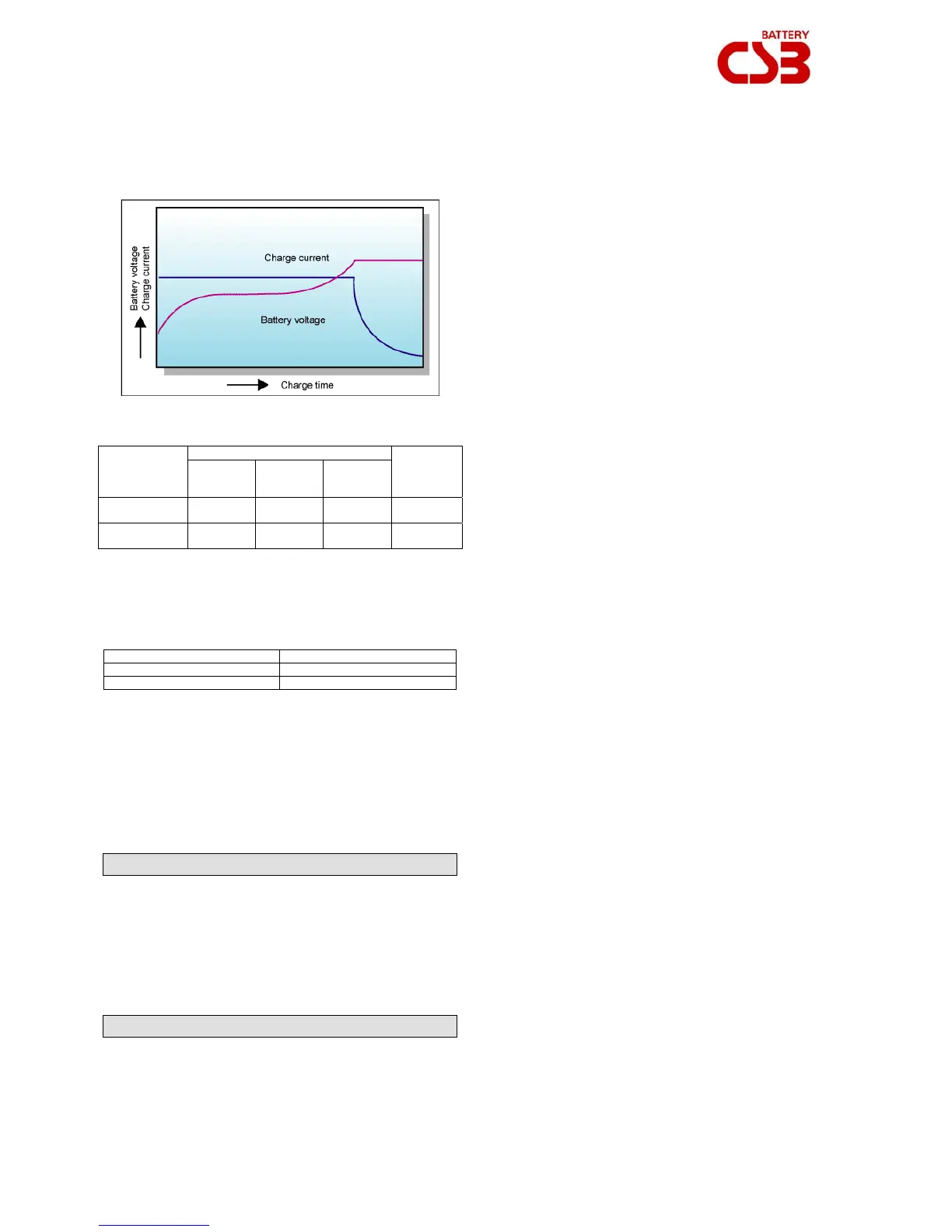

different voltage between its voltage and battery voltage. The

charging current is initially large and decreases towards the end of

charging. It is necessary to set the charging voltage according to

battery charging and temperature characteristics. Inaccurate voltage

causes an overcharge or an undercharge.

Graph 1 : Constant Voltage Characteristics.

Initial charging current should be 0.3CA or less, min 0.1CA.

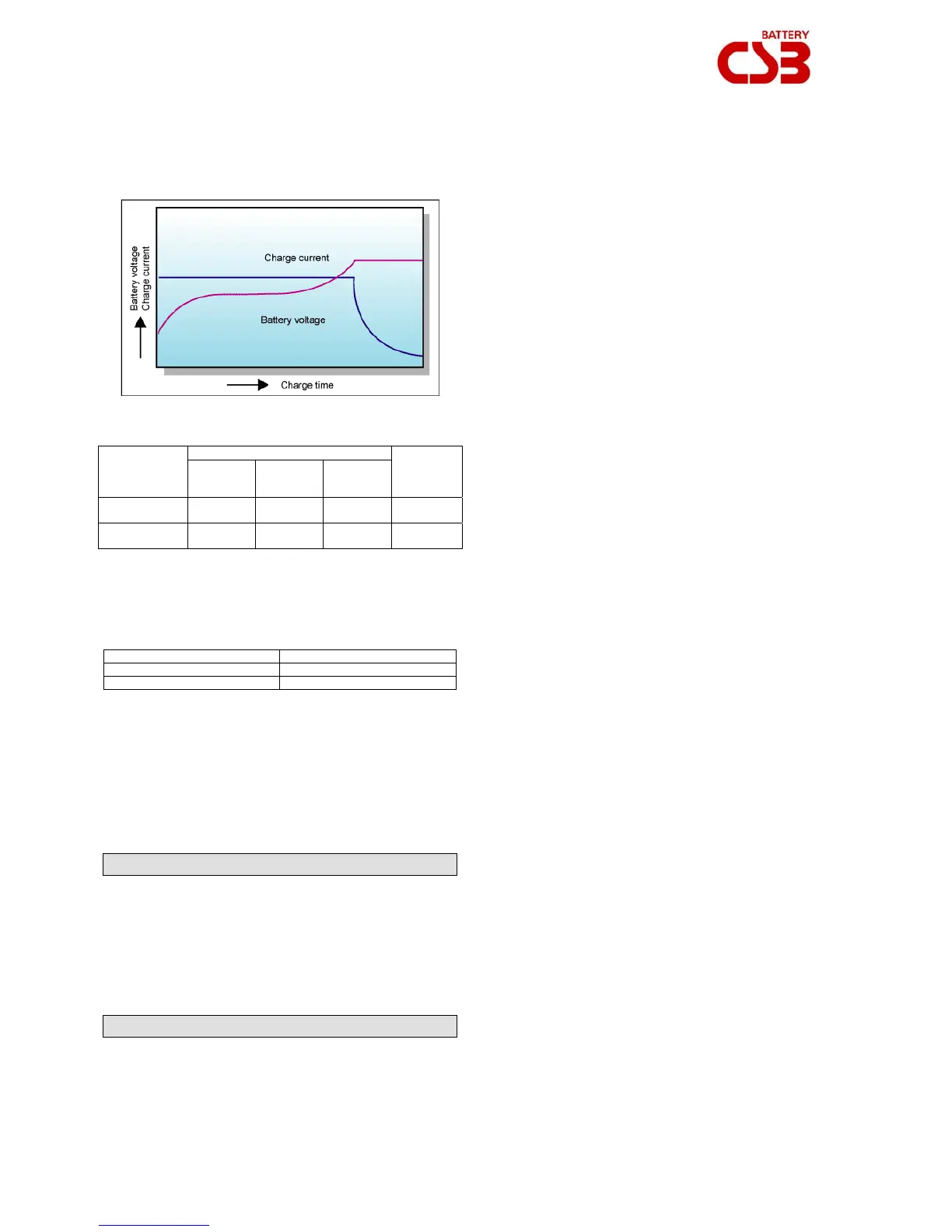

Table 4 : Charge voltage and maximum charge current.

Charging voltage in V/Cell

Applications

Temp.

in °C (°F)

Set point

Allowable

range

Max

charging

current

in A

Cycle service

25ºC

(77ºF)

2.45

2.40 ~ 2.50

0.3CA

Standby

25ºC

(77ºF)

2.275

2.25 ~ 2.30

0.3CA

Temperature compensation is not necessary when the battery is

charged at an ambient temperature between 5°C (41°F) to 35°C

(95°F), with average temperature below 25°C (77°F). At temperatures

below 5°C (41°F) or above 35°C (95°F), temperature compensation

for charging voltage is necessary.

Table 5 : Temperature coefficient.

Applications Temperature coefficient

Cycle service -5mV/ºC/cell

Standby -3.3mV/ºC/cell

When batteries are used in serial, a single current is imposed on all

the cells. However, if the voltages begin to differ, the result is a

charge imbalance. To restore balance or at least prevent it from

growing, equalization charging is required. Equalization charging

characteristics are a constant voltage of 2.45 V/cell for 5 to 8 hours.

More sophisticated charging methods are available : constant-

current, constant-voltage charging method, semi-constant current

charging method, constant current charging method, multi-steps

charging method, high frequency pulse charging method. Please

contact CSB Technical Support for more details.

8. Discharging.

• The continuous discharge and maximum discharge current (for 5

Seconds) should never exceed the values shown in Product

Specifications.

• Never discharge the battery until the voltage and current are less

than the values shown in Product Specifications. Repeated over

discharge will shorten the battery's life.

• After discharging, immediately recharge the battery. Never leave it

discharged. The capacity to hold a charge may not be recovered if

the battery is left discharged for a long period.

9. Periodic Inspections & Maintenance.

For optimum reliability, it is recommended that the battery system be

monitored quarterly. If the battery system incorporates an automatic

monitoring system to gather the electrical and environmental data,

the quarterly checks are limited to the evaluation of the recorded data

and a visual inspection of the battery.

In general the types of inspections to be made during periodic

maintenance include :

• Visual battery inspection,

• Battery system capacity test,

• Battery system voltage inspection,

• Ambient temperature,

• Individual battery float voltage inspection,

• High rate load test,

• Electrical resistance and tightness of inter-unit connections.

A test of the individual unit resistance, impedance or

conductance,

while optional, is also recommended on a periodic basis. This data

and its trends can be a valuable aid in troubleshooting the system

and predicting the need for a system capacity test.

Prior to starting the periodic maintenance activity assure that all the

required maintenance tools and equipment is available and

functional. Notify anyone who will be affected by the intended

maintenance or troubleshooting activity.

All units in the battery should be numbered so as to facilitate the

recording and analysis of data unique to each unit.

9.1 Quarterly VRLA Battery Inspection

• Assure the battery room is clean, free of debris and with proper

lighting.

• Assure that all facility safety equipment is available and functional.

• Measure and record the air temperature within the battery room.

• Visually inspect the battery for :

o Cleanliness,

o Terminal damage or evidence of heating,

o Container or cover damage.

• Measure the DC voltage from each polarity of the battery to

ground and detect any ground faults.

• Measure and record the individual unit DC float charging voltage,

and current.

• Measure and record the system equalization voltage, and current.

• Measure and record the temperature of the battery cabinet

inspections.

9.1 Semiannual VRLA Battery Inspection

• Repeat the quarterly inspection.

• Randomly measure and record the resistance/conductance of the

individual units to trend the condition of the individual units over

time and to detect dramatic differences between individual units

and the average.

9.3 Annual VRLA Battery Inspection

• Repeat the semiannual inspection

• Re-torque all of the inter-unit connecting hardware. This can be

omitted if the connection resistance is measured and found to

have not increased more than 20% from the value recorded at

installation

Loading...

Loading...