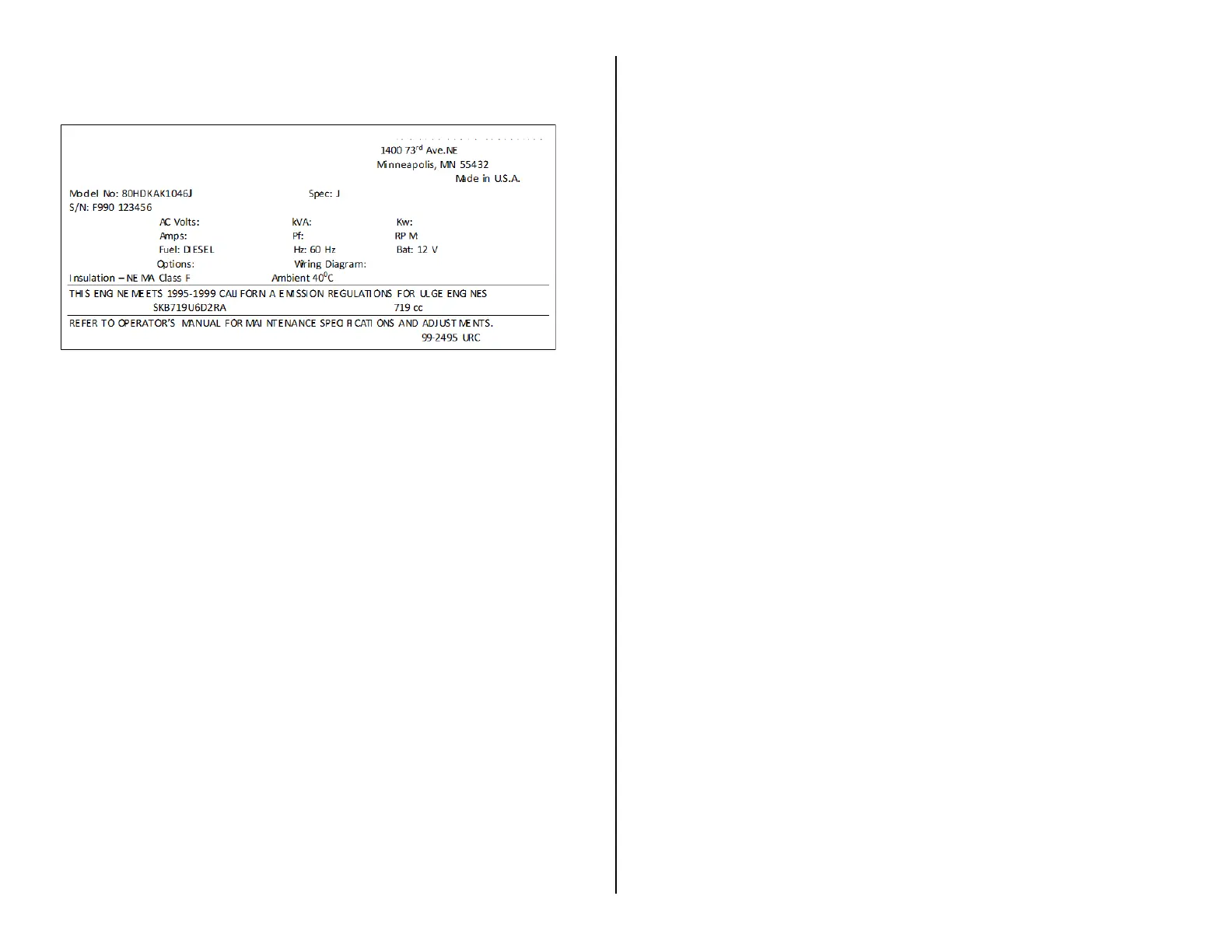

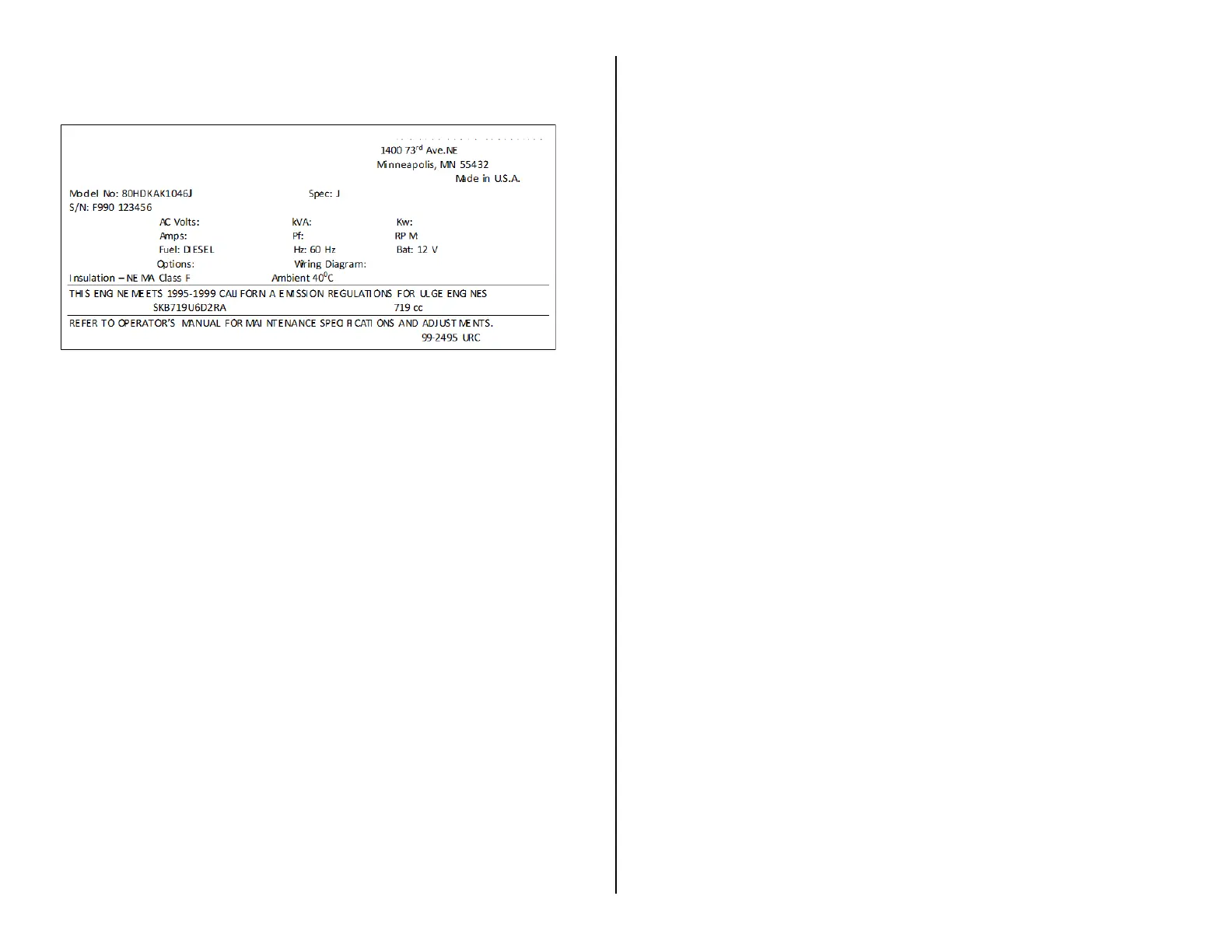

Generator Set Model and Nameplate

Each Cummins Onan generator set has a spec number description, which is shown on the

serial number tag attached to the generator.

Conducting General Inspections

Inspect the generator set before the first start of the day and after every eight hours of

operation.

Check generator set engine oil level.

Check the coolant level and look for leaking coolant. Minor leaks can be replenished

by daily additions of coolant in the recovery tank. Leaks should be serviced by a

qualified service technician as soon as possible. Larger leaks are cause for shutting

down the generator set until it can be serviced.

Look and listen for exhaust system leaks while the generator set is running. Shut

down the generator set if a leak is found and have it serviced before operating the

generator set.

Check for leaks on the fuel hose, tube and pipe fittings in the fuel supply system

while the generator set is running and while it is stopped.

Check the battery terminals for clean, tight connections. Loose or corroded

connections have high electrical resistance which makes starting of the generator

set harder.

Start the generator set and check for unusual noises and vibrations. Check the

generator set mounting bolts to make sure they are secure. Check to see that the

generator set air inlet and outlet openings are not clogged or blocked. Check the

engine gauges from time to time while the generator set is running (if equipped).

Replace the pressure cap (if equipped) every two years.

Pre-Start Checks

Make sure all vehicle CO detectors are working.

Check for signs of fuel and exhaust leaks.

Check for damage to the exhaust system.

Make sure the generator set’s normal ground clearance is not being reduced by

sloping curbs, logs or other objects to prevent overheating.

Turn off air conditioners and other large appliances.

Check the generator set engine oil level.

If the generator set (Commercial – Gasoline/LP) is equipped with a hydraulic pump,

check and refill oil reservoir as necessary.

Priming the Fuel System (as necessary)

If the generator set has run out of fuel, prime the fuel system. Hold the control switch at

STOP

/PRIME for at least 30 seconds for gasoline generator sets, and 1 minute for diesel

generator sets. The status indicator light stays on solid while the pump is on.

Copyright © 2020 Cummins Inc. Copyright © 2020 Cummins Inc.

Page 1 Page 2

Maintenance

Proper maintenance is critical to ensure maximum reliability, performance, and

efficiency of the generator sets. Recommended maintenance schedules differ between

the generator set models. Individualized maintenance schedules can be found in the

Operator Manual of each generator set model.

• Do not operate the generator set when the vehicle is in a confined space, such as

a garage.

• Inspect the generator set exhaust system for leaks before starting the generator

set and after eight hours of operating the generator set.

• If CO detectors are not installed in the vehicle, never occupy the vehicle while the

generator set is running.

• If CO detectors are installed in the vehicle, test the CO detectors for correct

operation before starting the generator set and after eight hours of operating the

generator set according to manufacturer’s instructions.

• Never use engine cooling air to heat working or living spaces or compartments.

• Disable automatic starting features before storing or parking the vehicle in a

garage or other confined space.

Figure 1. Nameplate Example

Installation

Do not attempt to install the generator set before reading the Installation Manual.

Note: RV generator sets must be installed, operated and maintained in accordance

with Cummins Inc. written instructions for use in recreational vehicles (“Pour

usage dans les vehicules recreatifs”).

Carbon Monoxide (CO)

Carbon Monoxide (CO) is present in the exhaust of the generator set. Carbon

Monoxide is poisonous and deadly.

Loading...

Loading...