2-2

Step 6. Attach DRAIN LINE to DRAIN LINE FITTING. To

prevent back pressure from reducing flow rate

below minimum required for backwash, DRAIN

LINE MUST be sized according to run length and

relative height. Be careful not to bend flexible drain

tubing sharply enough to cause "kinking" (if kinking

occurs DRAIN LINE MUST BE REPLACED). Typi-

cal examples of proper DRAIN LINE diameters are:

(1) 1/2 in. ID up to 15 ft. when discharge is lower

than INLET.

(2) 5/8 in. ID up to 15 ft. when discharge is slightly

higher than INLET.

(3) 3/4 in. ID when drain is 25 ft. away and/or drain

is installed overhead.

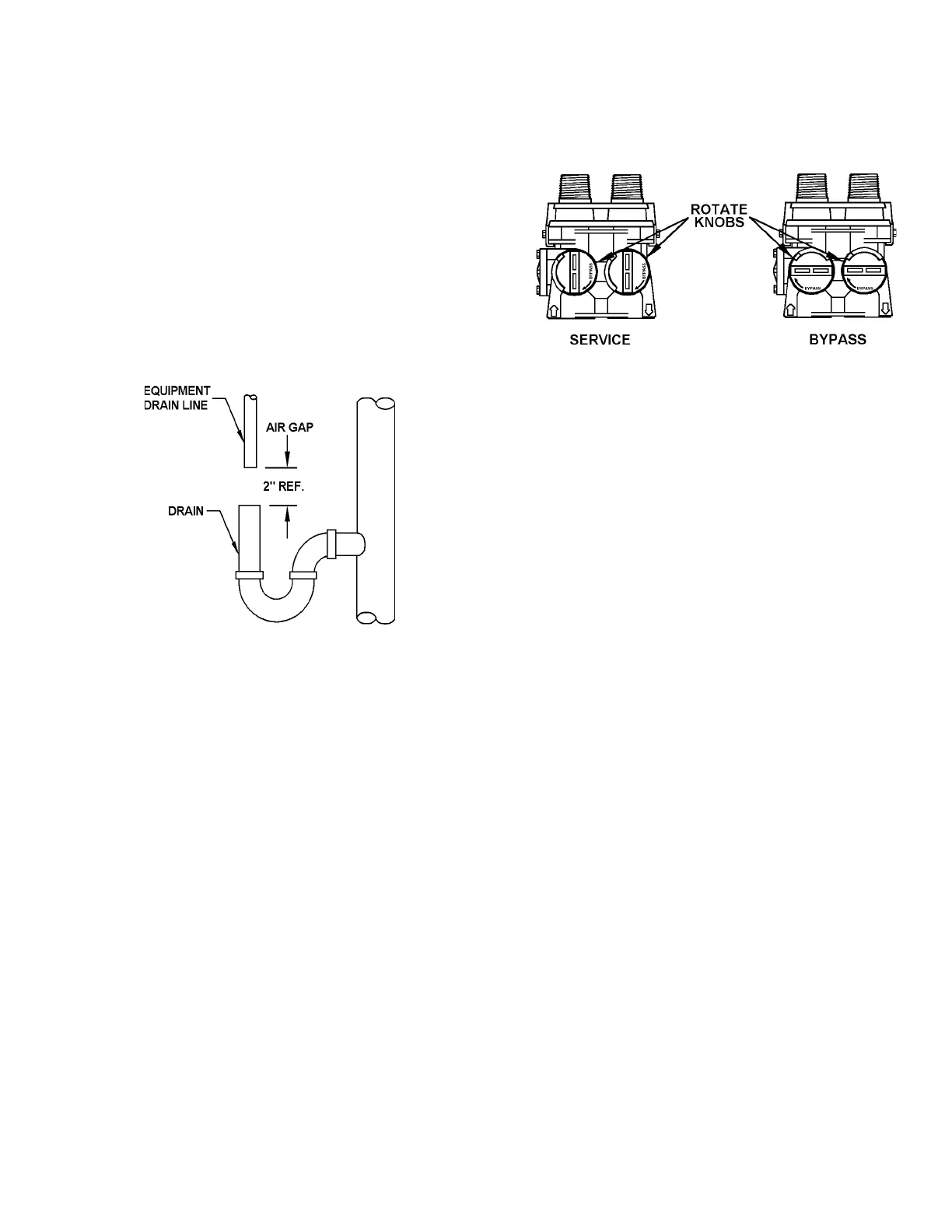

Figure 3. TYPICAL DRAIN

Step 7. Position DRAIN LINE over drain and secure firmly.

To prevent backsiphoning of waste water, provide

an air gap of at least 2 in. or 2 pipe diameters

between end of drain hose and drain (Figure 3). DO

NOT raise DRAIN LINE more than 10 ft. above floor.

Step 8. Connect one end of the 3/8 in. poly line to BRINE

VALVE located on the right side of CONTROL

VALVE. Connect other end to ELBOW inside of

BRINE WELL. Brass insert sleeves and plastic

ferrules must be used where necessary. (Figure 2

and CONTROL VALVE PARTS Drawing, Section

6).

Step 9. Install OVERFLOW LINE to brine tank OVERFLOW

FITTING (Figure 2). Discharge of line must be lower

than OVERFLOW FITTING. DO NOT INTERCON-

NECT OVERFLOW LINE WITH VALVE DRAIN

LINE.

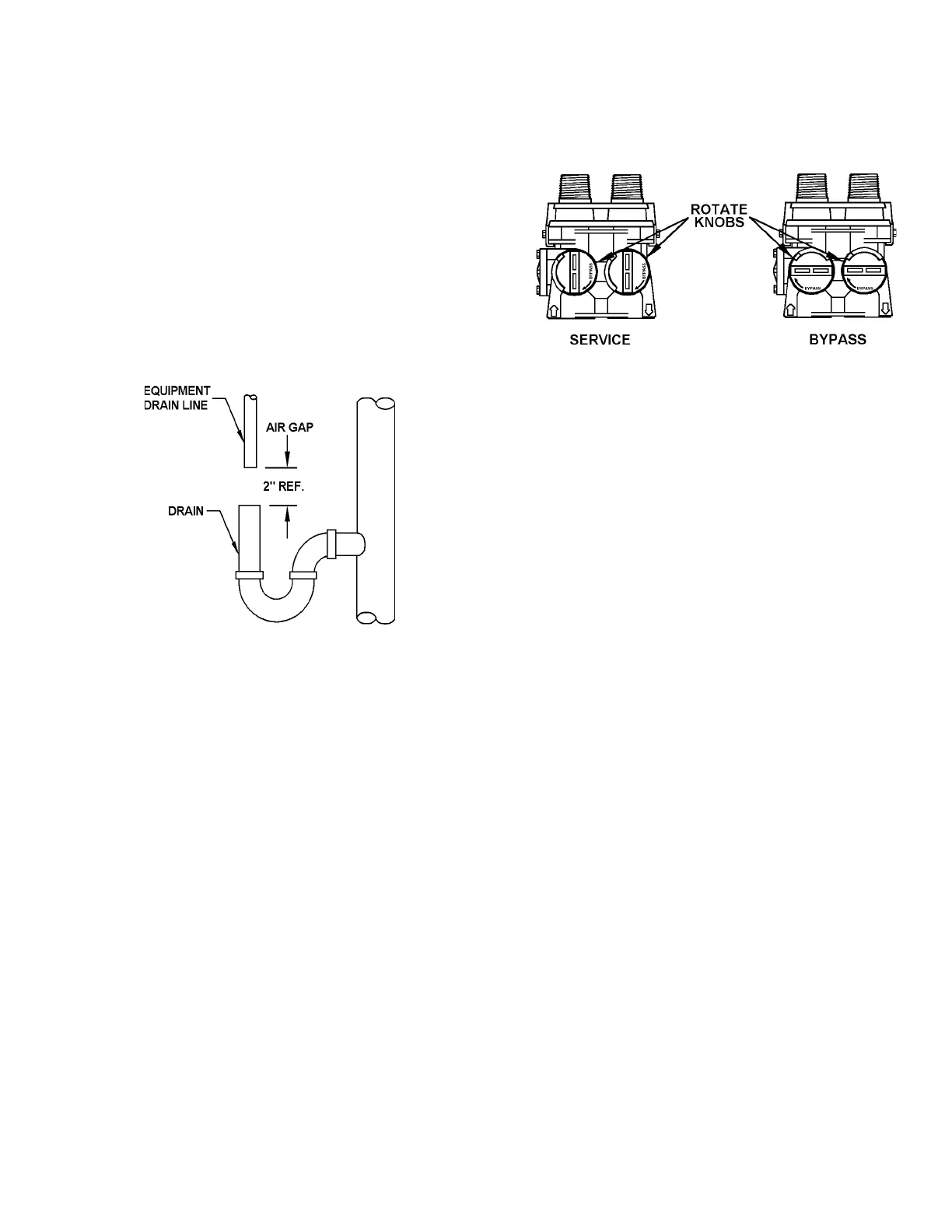

Step 10. Make certain BYPASS VALVE INLET and OUT-

LET KNOBS ARE IN "BYPASS" position. After all

plumbing connections have been completed, open

main water shut-off valve or restore power to well

pump. Check for leaks and correct as necessary.

Figure 4. BYPASS VALVE

Step 11. Manually stage control to BACKWASH POSI-

TION by turning "MANUAL REGENERATION

KNOB", clockwise to "BACKWASH" position, re-

fer to HOW TO SET TIME CLOCK REGENERA-

TION CONTROL (Section 3).

Step 12. Partially open INLET valve in plumbing or on

BYPASS VALVE (Figure 4). This will allow the

unit to fill slowly from the bottom up, eliminating air

entrapment. Allow unit to fill slowly, failure to do

so could result in loss of resin to the drain. Once

a steady stream of water, no air, is flowing to drain,

the INLET VALVE can be fully opened. The

OUTLET valve can also be opened and the BY-

PASS (if applicable) can be closed. Manually

advance control to SERVICE POSITION. Plug

into a non-switched 110/120V, 60Hz power source.

Step 13. On time clock initiated models, set REGENERA-

TION FREQUENCY. Refer to REGENERATION

FREQUENCY SCHEDULES (Section 3) to deter-

mine correct frequency, then refer to HOW TO

SET TIME CLOCK REGENERATION CONTROL

(Section 3) for instructions on setting frequency.

For meter initiated models, refer to HOW TO SET

METER REGENERATION CONTROL.

NOTE: Regeneration settings for both time clock

and meter initiated models are factory preset for

the most efficient salt use and minimum water

consumption used for regeneration (as little as 50

gallons), and conform to the INDUSTRY SALT

EFFICIENCY STANDARDS (required by some

states). REGENERATION FREQUENCY

SCHEDULES are designed for use with factory

regeneration settings (listed in SPECIFICATIONS

AND OPERATING DATA, Section 5).

Loading...

Loading...