3

ZF 6S-850 GEARBOX

Component description CF65/75/85 series

2-2

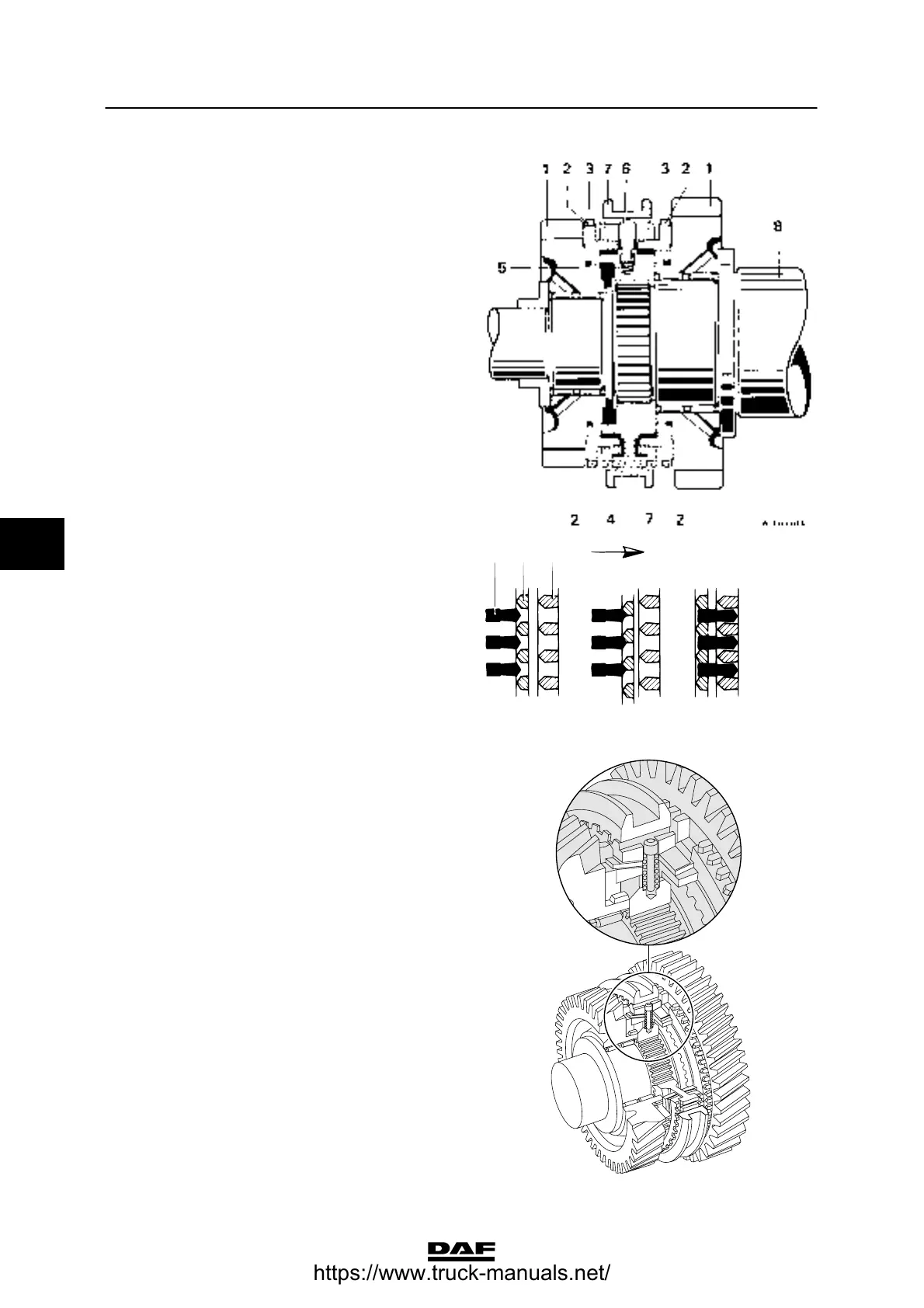

As a result of continued pressure on the

synchroniser sleeve (7) (friction), the speed of

the gear (1) to be shifted with the clutch body (2)

matches the speed of the main shaft (8).

The bevelled sides of the teeth on the

synchromesh ring (3) and the synchroniser

sleeve (7) cause the synchromesh ring (3) to be

turned back slightly after synchronisation.

This releases the lock and allows the

synchroniser sleeve (7) to be moved into the

teeth of the clutch body (2).

Hence the relevant gear is engaged.

A. Not engaged

B. Synchronise

C. Engaged

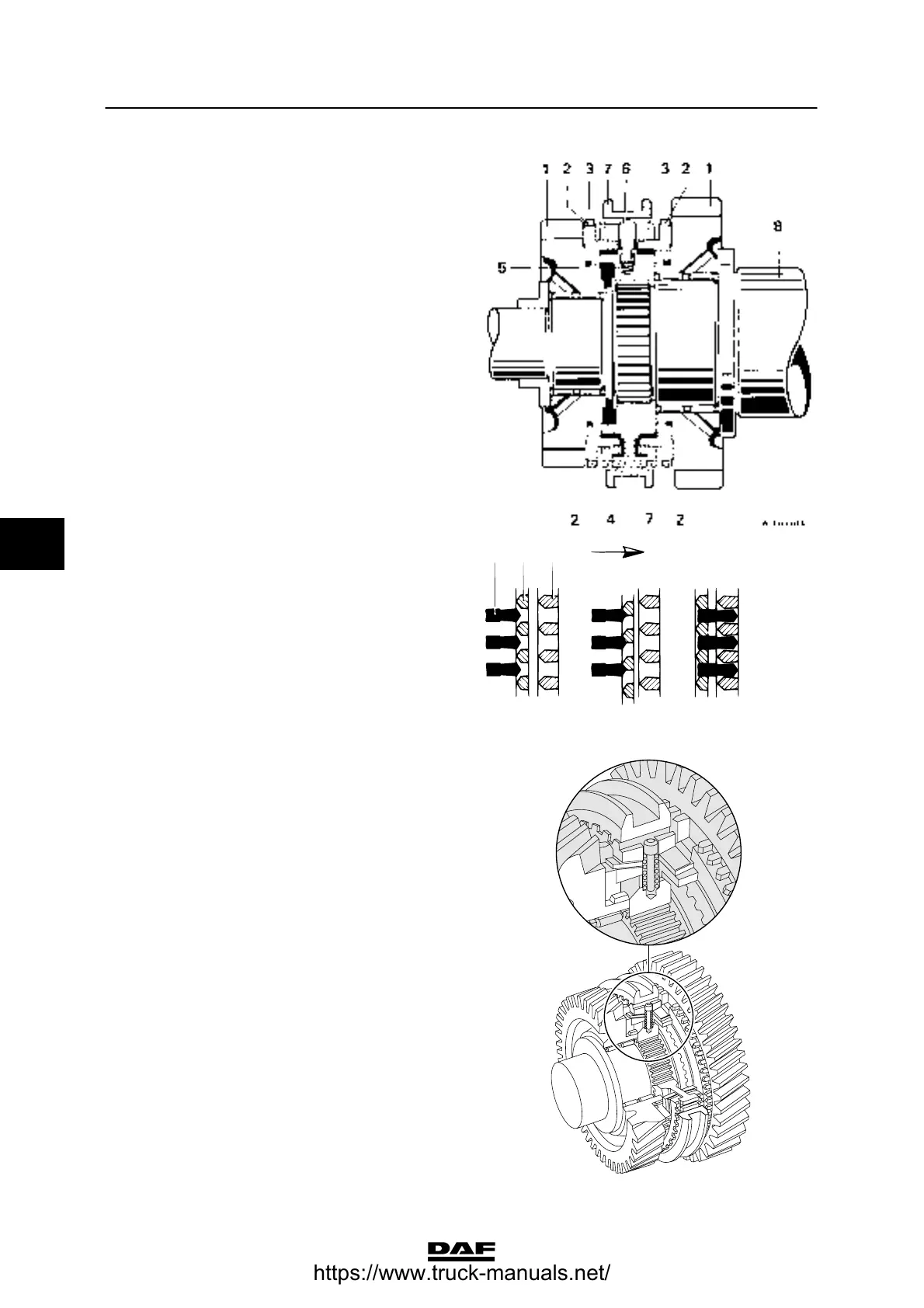

Double-cone synchronisation

As a result of the speed difference to be

eliminated in the lower gears, the

synchronisation forces may be considerable. In

order to achieve effective synchronisation, a

synchroniser with a double cone is used.

This synchroniser consists of an outer and an

inner ring (synchromesh rings) connected to the

main shaft of the gearbox by means of the

selector sleeve support.

The ring between the two synchromesh rings is

connected to the gear wheel by means of the

clutch body.

When the selector sleeve moves into the clutch

body, two synchronisation surfaces are active.

W 3 03 015

ABC

732

W 3 03 047

ᓻ 0111

5

https://www.truck-manuals.net/

Loading...

Loading...