3

CLUTCH

Description of components CF65/75/85 series

3-10

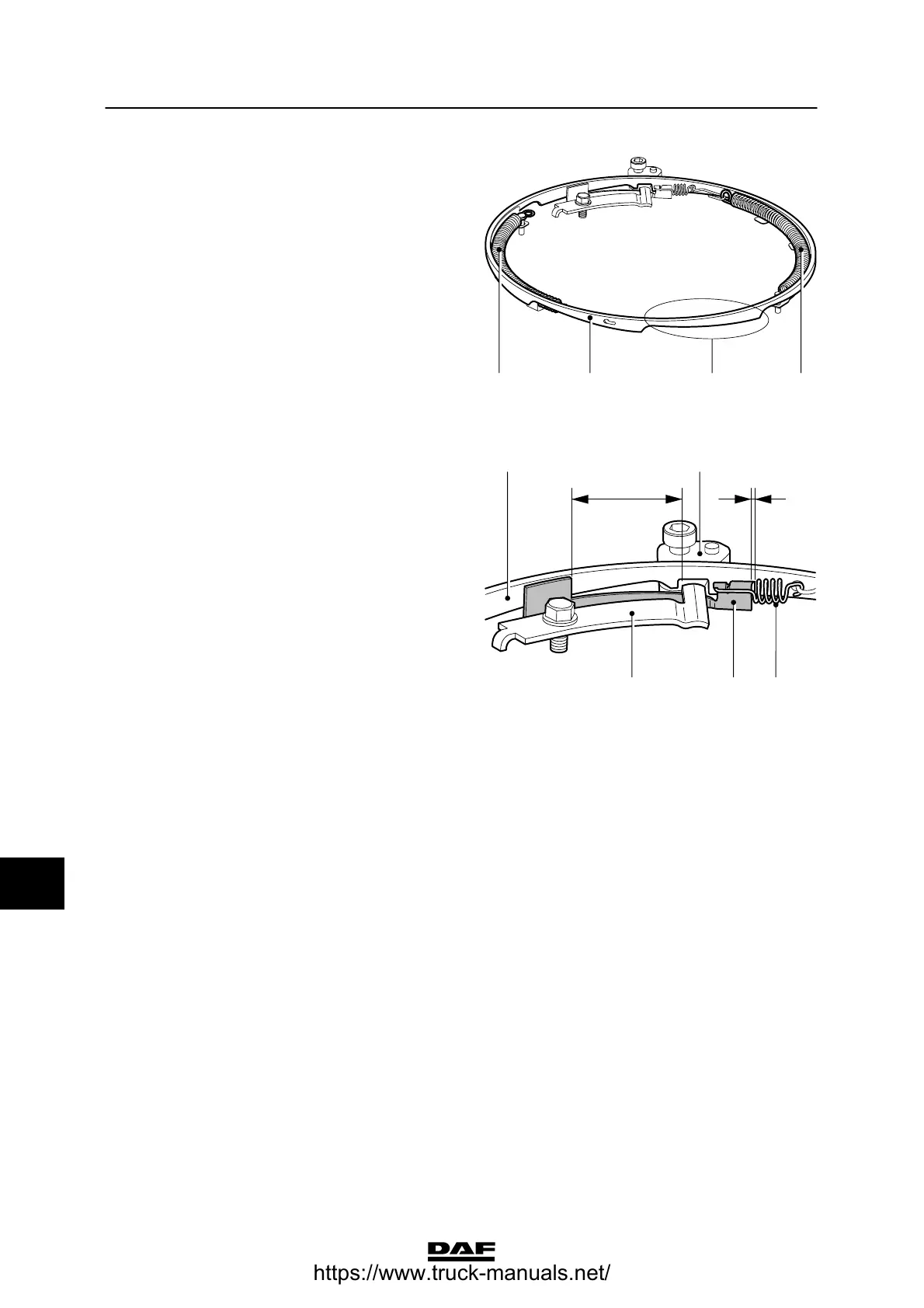

The adjusting ring (6) twists as a result of the

tension applied by the adjusting springs (10).

The adjusting ring twists by the same amount as

the former gap (B) in the recess in the adjusting

ring (6).

The contact surface (E) between the adjusting

ring and the thrust plate is wedge-shaped.

Adjusting the adjusting ring (6) causes it to move

upwards. This causes the space (C) between

the thrust plate (1) and the diaphragm spring (8)

to close. When the clutch is no longer being

used, the diaphragm spring will return to the

same rest position. This procedure

compensates for wear in the clutch plate and

ensures that the diaphragm spring always

returns to the same rest position.

V300486

5 E 1010

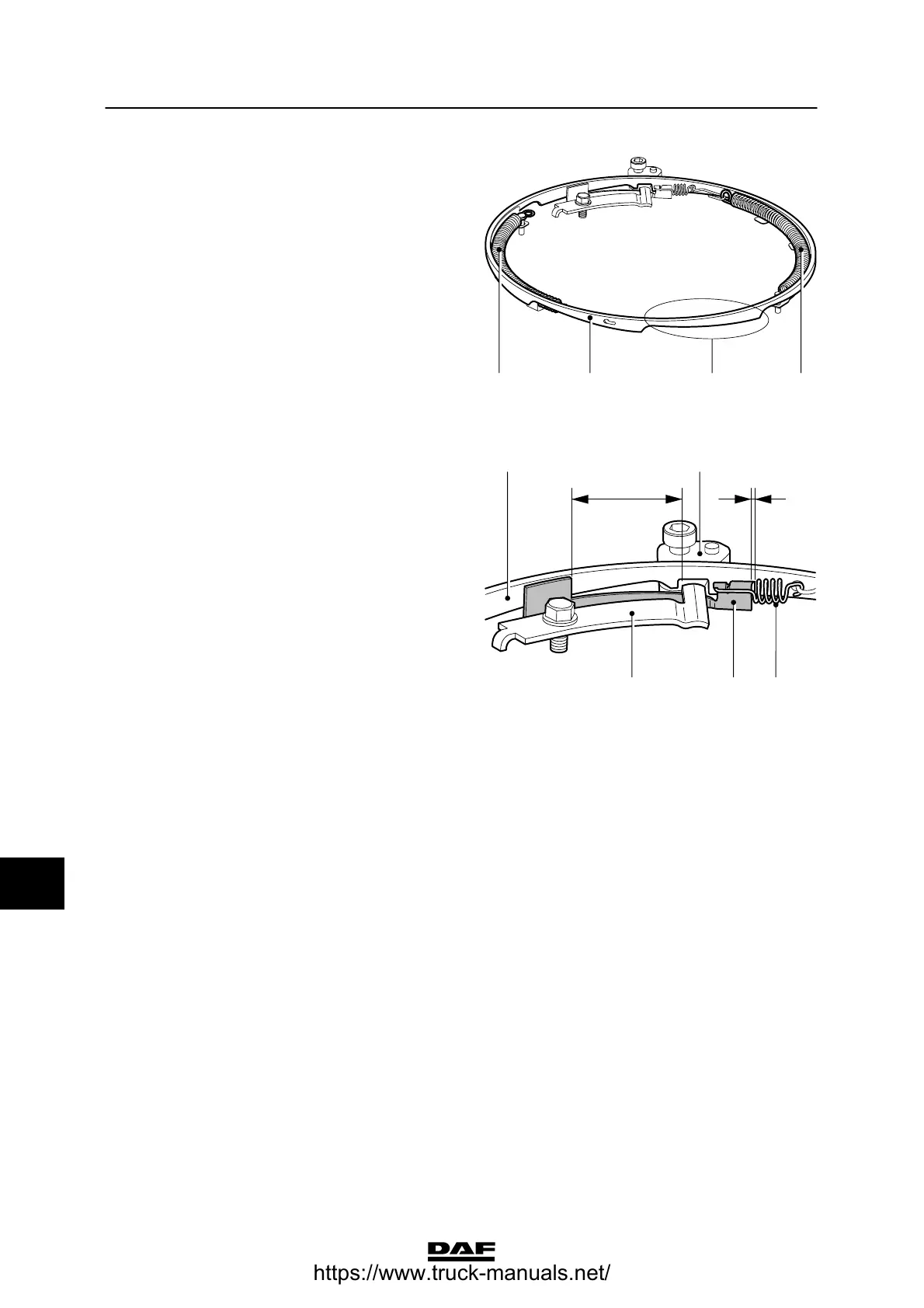

Compensation occurs during the first 4 mm of

clutch plate wear.

This is determined by the maximum adjustment

distance (D). Adjustment ceases when the slide

plate (7) rests against the stop of the stop

spring (5).

Once the clutch plate has worn by 4 mm, the

automatically adjusting clutch behaves as a

conventional clutch if there is any further wear.

In other words, the position of the diaphragm

spring will change once there is more than 4 mm

of wear.

This results in a change in the position of the

clutch lever and the clutch servo thrust pin and

in the position of the wear indicator. The

wear indicator will only give a wear indication

during the last millimetre of wear of the clutch

plate lining.

V300485

6

BD

2

9

75

10

ᓻ 200337

https://www.truck-manuals.net/

Loading...

Loading...