Donotmixsubstanceotherthanthespeciedrefriger-

ant such as air into the refrigeration circuit.

If the refrigerant leaks during the work, ventilate the

room.

• The refrigerant is pre-charged in the outdoor unit.

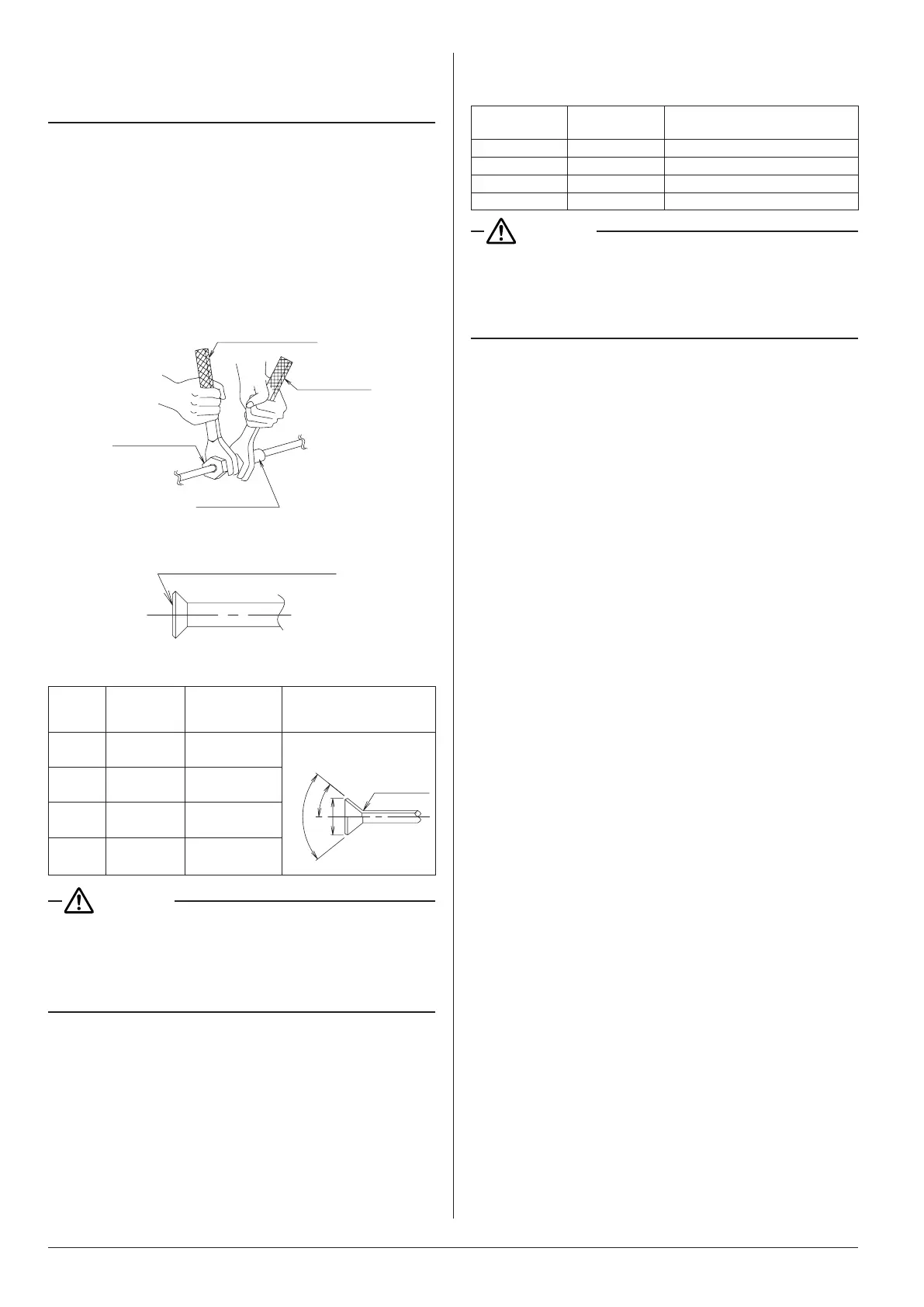

• When connecting the pipings to the air conditioner, make

sure to use a spanner and a torque wrench as shown in

Fig. 10.

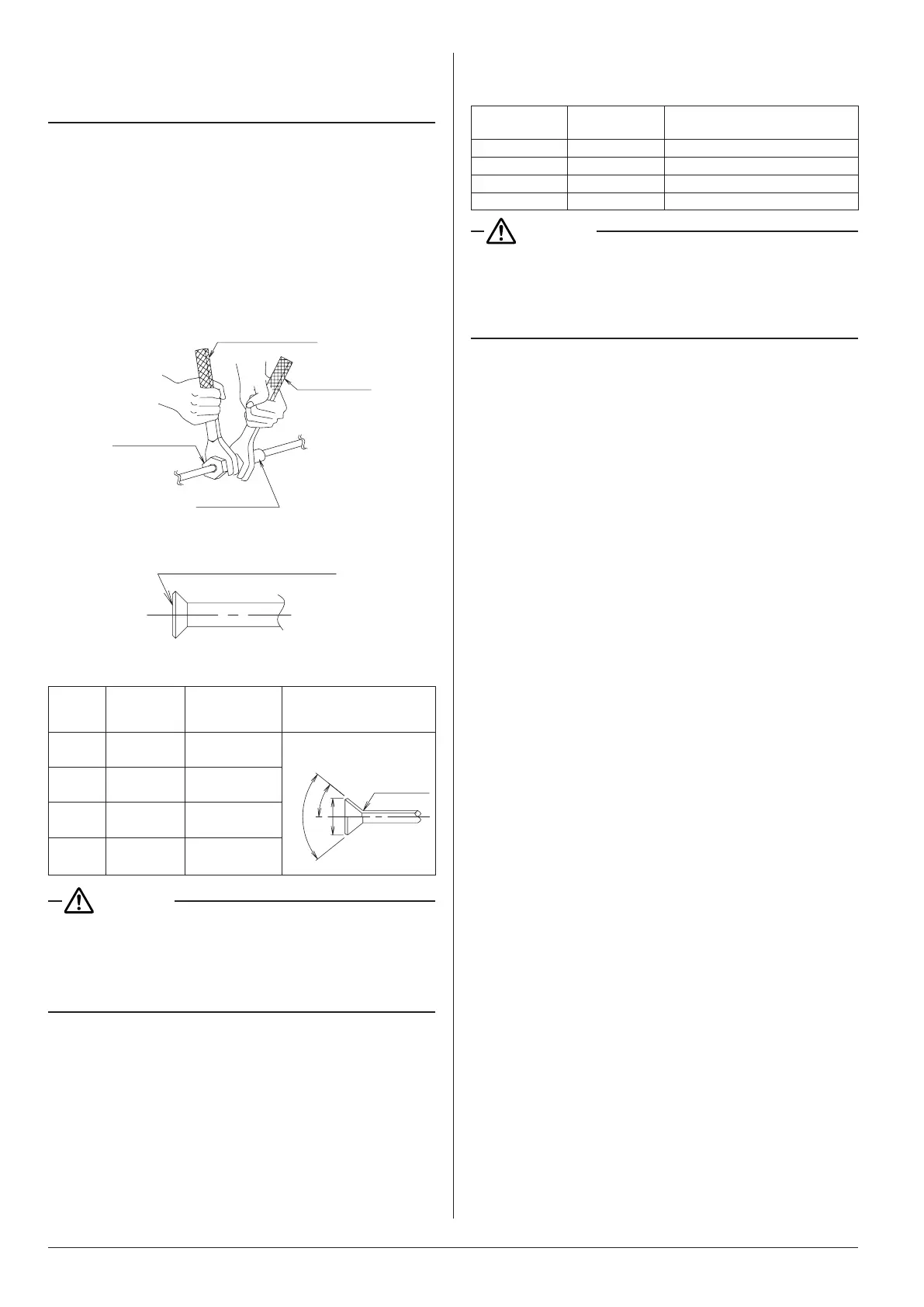

• Forthedimensionofaredpartandthetighteningtorque,

refer to the Table 2.

• Whenmakingaareconnection,coatthearedinner

surface only with ether oil or ester oil.

(Refer to Fig. 11)

Then,turnthearenut3to4timeswithyourhandand

screw in the nut.

Spanner

Flare nut

Union joint

Fig. 10

Coat the flared inner surface

only with ether oil or ester oil

Fig. 11

Table 2

Piping

size

(mm)

Tightening

torque

(N·m)

Dimension for

processing flare

A (mm)

Flare shape

f

6.4

15.7 ± 1.5 8.9 ± 0.2

R0.4-0.8

A

f 9.5

36.3 ± 3.6 13.0 ± 0.2

f

12.7

54.9 ± 5.4 16.4 ± 0.2

f

15.9

68.6 ± 6.8 19.5 ± 0.2

CAUTION

Donothaveoiladheretothescrewxingpartofresin

parts.

If oil adheres, it may weaken the strength of screwed part.

Donottightenarenutstootight.

If a flare nut cracks, the refrigerant may leak.

• If there is no torque wrench, use Table 3 as a rule of

thumb.

Whentighteningaarenutwithaspannerharderand

harder, there is a point where the tightening torque sud-

denly increases.

From that position, tighten the nut additionally the angle

shown in Table 3.

Aftertheworkisnished,checksecurelythatthereisno

gas leak.

If the nut is not tightened as instructed, it may cause slow

refrigerant leak and result in malfunction (such as does

not cool or heat).

Table 3

Piping size

(mm)

Tightening

angle

Recommended arm length of

tool used

f 6.4 60° - 90° approx. 150 mm

f 9.5 60° - 90° approx. 200 mm

f 12.7 30° - 60° approx. 250 mm

f 15.9 30° - 60° approx. 300 mm

CAUTION

Insulationofeldpipingmustbecarriedoutuptothe

connection inside the casing.

If the piping is exposed to the atmosphere, it may cause

sweating, burn due to touching the piping, electric shocks or

a fire due to the wiring touching the piping.

• After leak test, referring to Fig. 12, insulate both the gas

and liquid piping connection with the attached joint in-

sulating material (8) and (9) to prevent the pipings from

getting exposed.

Then, tighten the both ends of insulating material with the

clamp (4).

• Wrap the sealing material (Medium-1, 2) (11) (12) around

thejointinsulatingmaterial(8)and(9)(arenutsection),

both the gas and liquid piping.

• Make sure to bring the seam of joint insulating material (8)

and (9) to the top.

7 3P335596-2D English

Loading...

Loading...