Agoodqualitynon-returnvalvemustbeinstalled

inthepressurepumpoutletpipeworkbeforethe

hotwaterservice.Failuretoinstallthisnon-return

valvemayresultinpumpdamage.Suchdamage

isnotcoveredbyguarantee.

Connection of Mains Scheme or Town Wa-

ter Supply to either Suction or Discharge of

Pumps & Pressure Systems

MostWaterSupplyAuthoritieshavestrictregu-

lationsregardingdirectconnectionofpumpsto

mainswatersupplies.Inmostcasesanisolating

tankisrequiredbetweenmainssupplyandpump.Daveyalsorecommendthis

method.Directlyappliedmainspressurecanexceedpumpoperatingpressure

anddamagepump.

Davey Water Products

Pty Ltd can not accept

responsibility for loss or

damage resulting from

incorrect or unauthorised

installations.

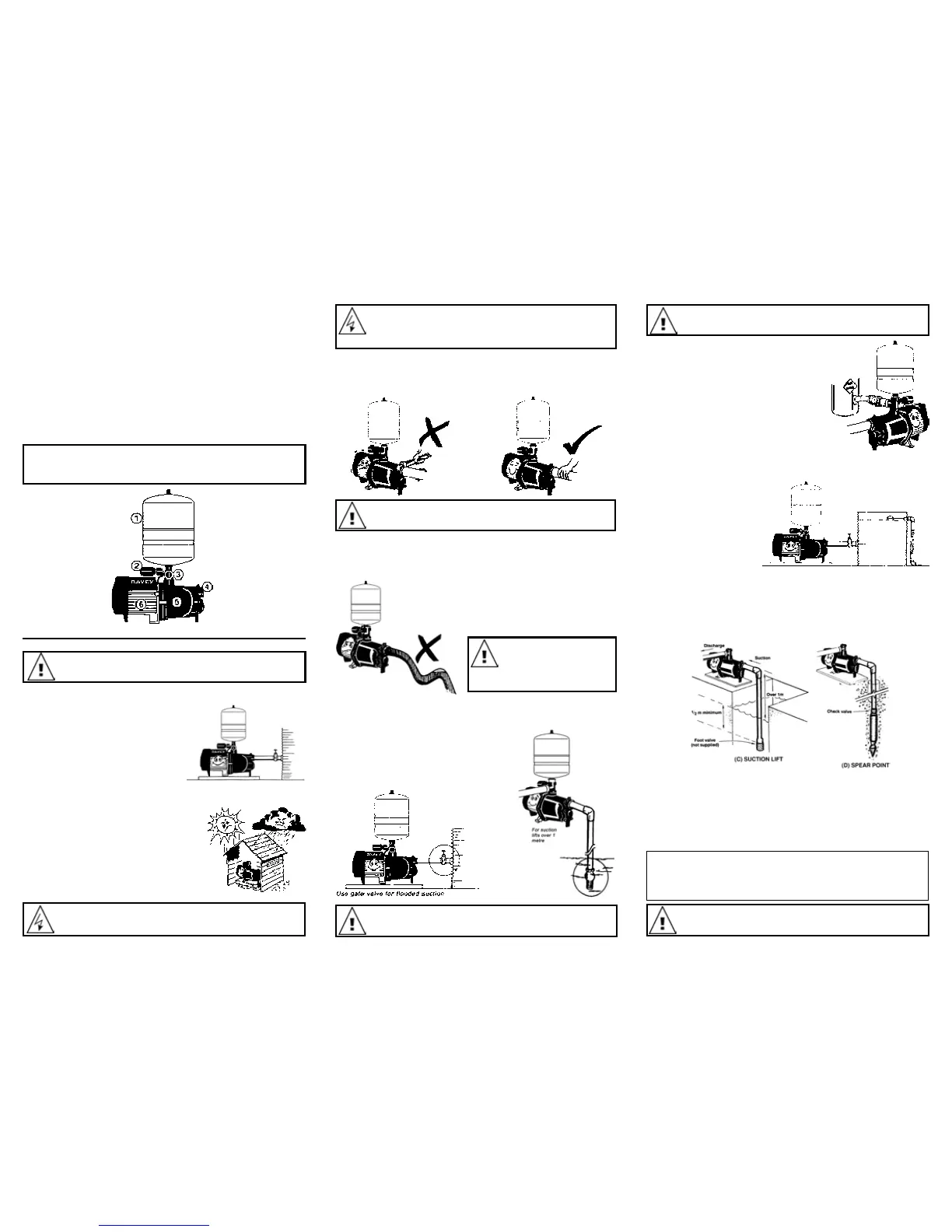

Connection to your Water Source

BELOW GROUND WATER SOURCES

Whenevertheinstallationpositionofthepumpishigherthan1m(3.3ft)above

thelowestwaterlevel,afootvalvemustbeusedontheendofthesuctionpipe

asillustratedin(C)below.Ensurethatthefootvalveisatleast

1

/

2

metrebelow

minimumwaterlevel.

SPEAR POINT INSTALLATIONS

WhenaDynajet®isinstalledonaspearorwellpoint,acheckvalvemustbe

ttedimmediatelyontopofthespearpointitself,asshownin(D)above.DO

NOT INSTALL THE CHECK VALVE AT THE PUMP OR AT THE TOP OF THE

WELL. DO NOT RUN THE PUMP WITHOUT WATER.

NOTE: Be certain to select the spear point to suit the well conditions and

regulate the ow rate from the pump accordingly.

SPEAR SIZE MESH APPROX. MAX. CAPACITY OF SPEAR

POINT

1

1

/

4

”(32mm) 60 15-231/minor200-300gal/hr

1

1

/

2

”(38mm) 60 23-381/minor300-500gal/hr

2”(50mm) 60 38-751/minor500-1000gal/hr

WARNING: Some insects, such as small ants, nd electrical devices

attractive for various reasons. If your pump enclosure is susceptible

to insect infestation you should implement a suitable pest control plan.

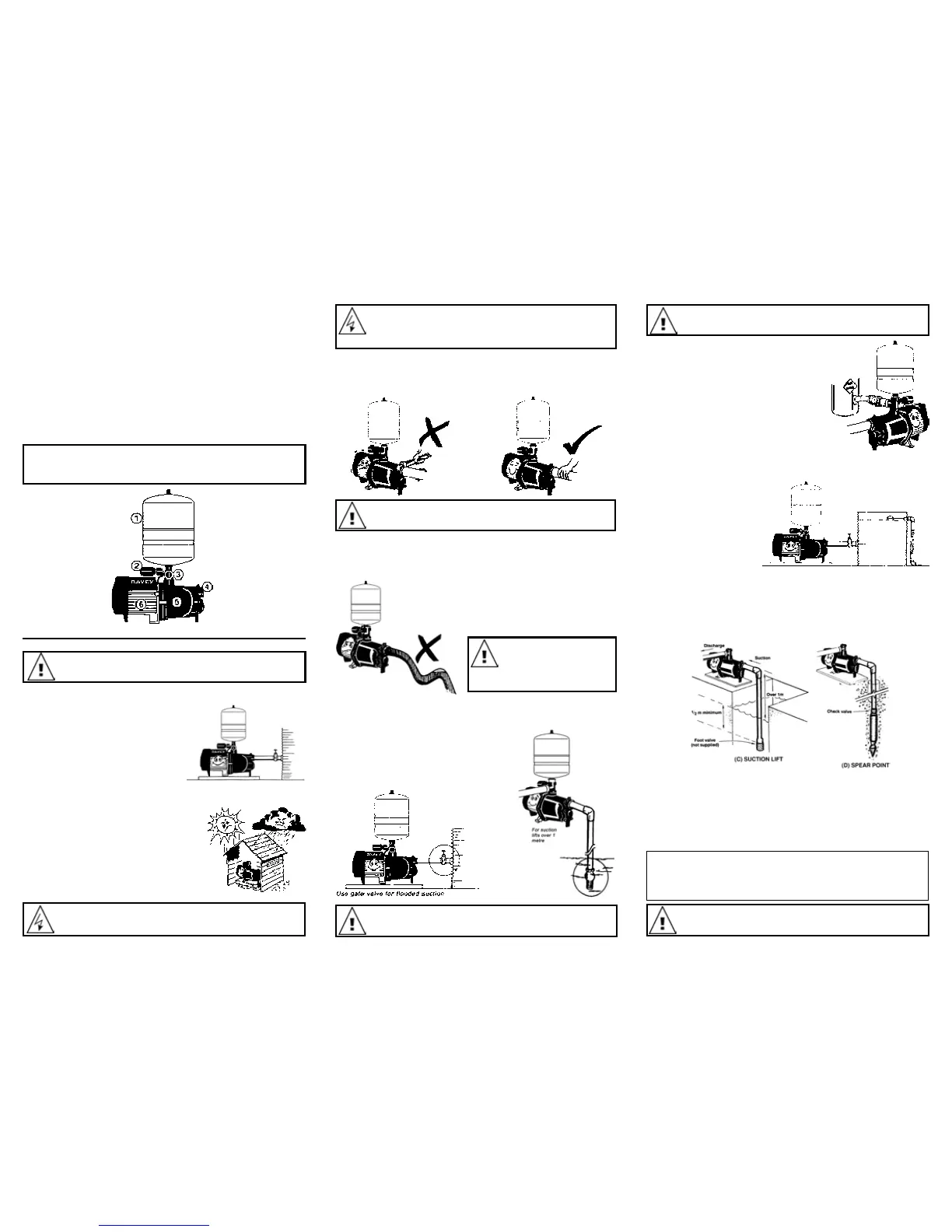

Choosing a Site

Chooseasitewitharmbaseandasclose

tothewatersourceaspossiblewithcorrect

powersupply.Makesureyourpressure

systemisalwaysconnectedtoanadequate,

reliablesourceofcleanwater.

Housing your Davey Pressure System

Toprotectyourpressuresystemfromtheweather,

makesurethepumphouseisbothwaterproof,

frostfreeandhasadequateventilation.Thepump

shouldbehorizontallymountedonarmbase

allowingfordrainage,toavoiddamagetoooring

etc.,thatovertimemayoccurfromleakingpipe

jointsorpumpseals.Donotmountthepump

vertically.

Pipe Connections

ForbestperformanceuseP.V.C.orpolythenepipesatleastthesame

diameterasthepump’sinletanddeliveryoutletopenings.Largerdiameter

pipemaybeusedtominimiseresistancetoowwhenpumpinglonger

distances.

Useunionsatpipeconnectionstoenableeasyremovalandservicing.Use

sufcienttapetoensureairtightsealandhandtightenonly.Topreventstrain

onpumpthreadsalwayssupportheavyinletandoutletpipes.Ifthereisa

likelihoodthewatersupplymaycontainsolidparticlessuchaspiecesofplant

orvegetablematter,asuctionstrainer

shouldbeinstalledbeforethepumpto

avoidblockingofthepump.Laysuction

pipeataconstantgradienttoavoid

airpocketswhichmayreducepump

efciency.

Where to use Check Valves and Foot Valves

Installationswithasuctionliftover1mrequire

agoodqualityfootvalvetoavoidlossofprime.

Inthiscase,thepoppetvalveinsidethepump

shouldberemoved.Installationswithooded

suctionrequireagatevalvesowatersupplycan

beturnedoffforpumpremovalandservicing.

Priortousingthispumpyoumustensurethat:

• Thepumpisinstalledinasafeanddryenvironment

• Thepumpenclosurehasadequatedrainageintheeventofleakage

• Anytransportplugsareremoved

• Thepipe-workiscorrectlysealedandsupported

• Thepumpisprimedcorrectly

• Thepowersupplyiscorrectlyconnected

• Allstepshavebeentakenforsafeoperation

AppropriatedetailsforalloftheseitemsarecontainedinthefollowingInstallationand

OperatingInstructions.Readtheseintheirentiretybeforeswitchingonthispump.Ifyou

areuncertainastoanyoftheseInstallationandOperatingInstructionspleasecontact

yourDaveydealerortheappropriateDaveyofceaslistedonthebackofthisdocument.

Congratulationsonyourpurchaseofahighquality,AustralianbuiltDaveypressure

pump.Allcomponentshavebeendesignedandmanufacturedtogivetroublefree,

reliableoperation.

XJ Ultra / XJ70P / XJ90P

1. Pressuretank

(suppliedseparately)

2. Pressureswitch

3. Deliveryoutlet(1”F)

4. Suction inlet

(XJUltra=1”F)

(XJ70P&XJ90P=1

1

/

4

”F)

5. Pump body

6. Motor

XJ50 / XJ70 / XJ90

Arethesameasabove

lessitems1&2.

Note: YourXJUltra,XJ70P&

XJ90Ppumpisdesignedtooper-

ateasanautomaticpressuresys-

temwhenusedinconjunctionwith

apressuretanksuchasaDavey

“Supercell18C”tank(illustrated).

Thetank,suppliedseparately,

needstobettedtothedelivery

outletpriortooperating.

Assembly

Attachpressureswitch(2)

tothedeliveryoutlettee(3)

byhandtighteningthepres-

sureswitchunionnut(ensure

sealingoringisinplace).

Screwpressuretank(1)onto

deliveryoutlet.

Power Connection

Connect lead to power supply designated on pump label, do not use

long extension leads as they cause substantial voltage drop, poor

pump performance and may cause motor overload.

Before installing your new pump, please read all instructions carefully as failures caused

by incorrect installation or operation are not covered by the guarantee. Your Dynajet®

XJ pump is designed to handle clean water. It should not be used for any other purpose

without specic referral to Davey. The use of the pump to handle ammable, corrosive

and other materials of a hazardous nature is specically excluded.

Do not use this pump to pump ammable uids, such as petrol or

diesel fuels.

Do not use pipe thread sealing compounds on any part of this pump.

ONLY use Teon sealing tape.

NOTE: Suction leaks are the

largest cause of poor pump

performance and are difcult

to detect. Ensure all

connections are completely

sealed using thread tape only.

IMPORTANT

For Automatic Pressure Pumps Installed with a Mains Pressure Hot

Water System.

Abrasive Materials

The pumping of abrasive materials will cause damage to the

pressure system which will then not be covered by the guarantee.

Spear point ow capacities vary considerably. Check with the supplier

to ensure the pump and spear point are correctly matched.

Loading...

Loading...