67

sliding gate Swing gate overhead door barriers

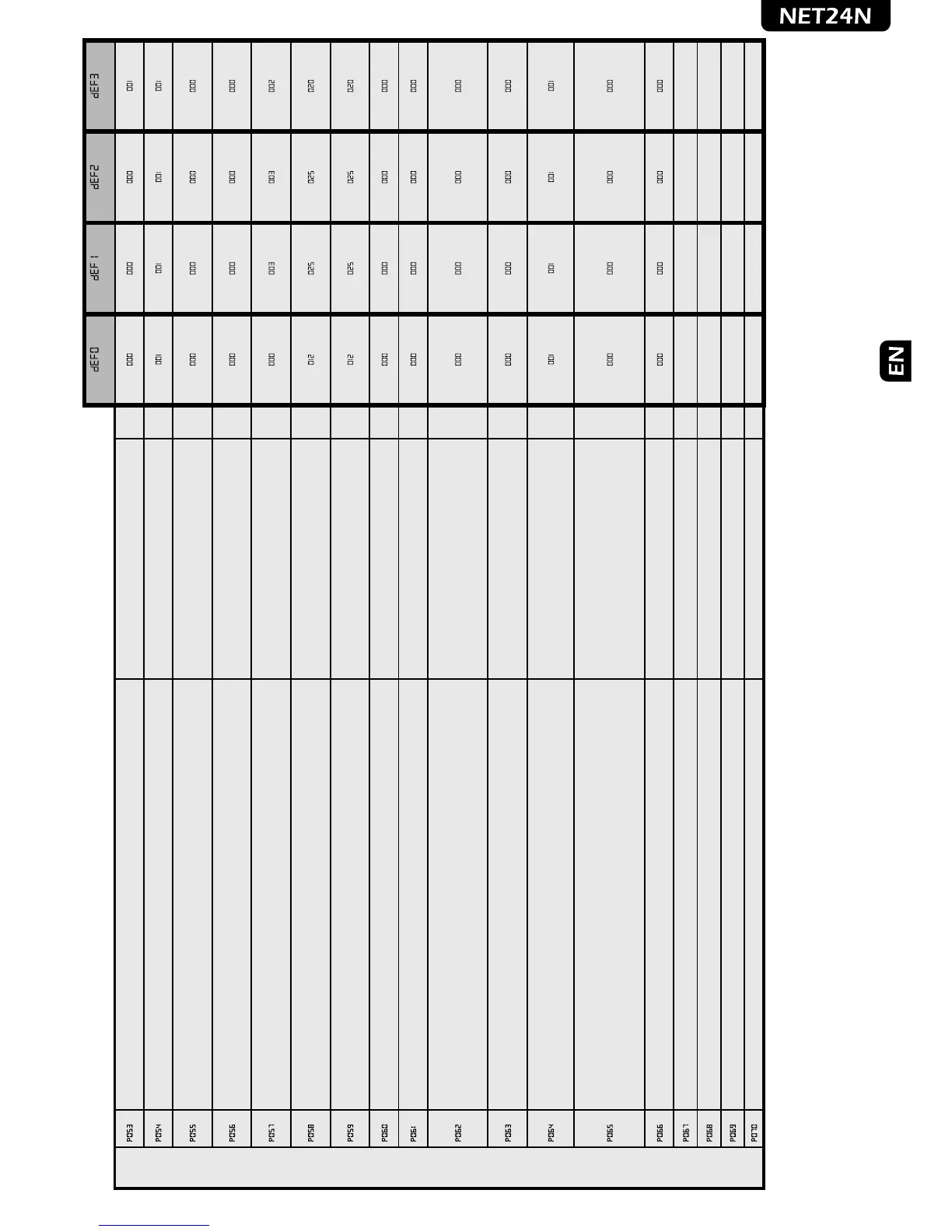

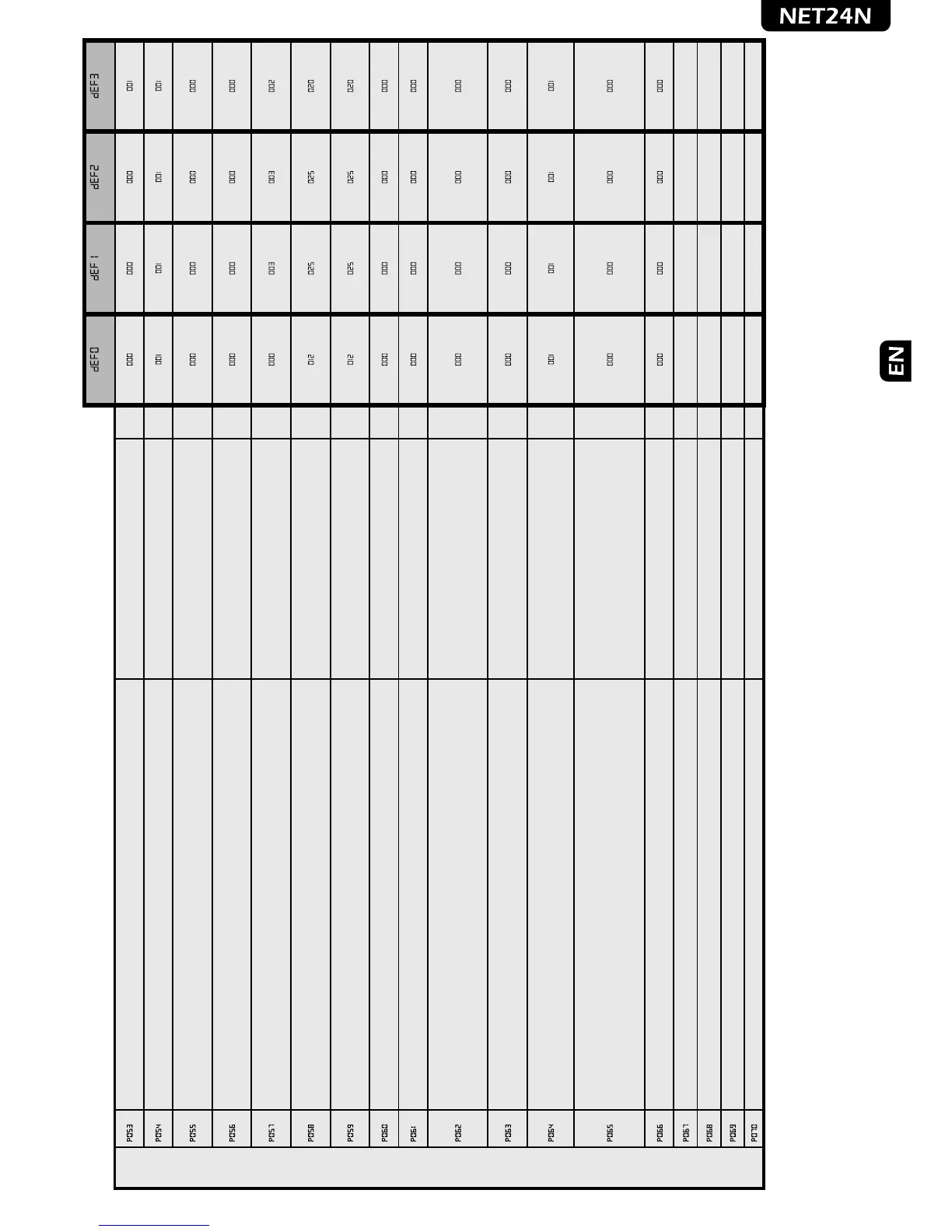

OPERATING PARAMETERS

Searches for end of stroke while opening too: when activated, operators stop only at their arrival et the end

of stroke, also while opening.

• 000: Stop when opening on a memorized point

• 001: Stop when opening on the end of stroke

“soft start” function: motors accelerate gradually until they reach the set speed, avoiding sudden departures • 000: “soft start” deactivated

• 001: “soft start” activated

Adjust the inversion on obstacle period (detected by internal anti-crushing sensor or by the safety input when

activated): If = 0 it makes a complete inversion, if> 0 indicates the duration (in seconds) of the run, after

inversion resulting from detection of an obstacle during the opening.

• 000: inversione completa su ostacolo

• >000: durata dell’inversione su ostacolo

(1sec……………..10sec)

Adjust the inversion on obstacle period (detected by internal anti-crushing sensor or by the safety input when

activated): If = 0 it makes a complete inversion, if> 0 indicates the duration (in seconds) of the run, after

inversion resulting from detection of an obstacle during the closing.

• 000: complete reversal on obstacle

• >000: duration of reversal on obstacle

(1sec……………..10sec)

Facilitation manual release: If≠0, after detecting the locking stop, the engine reverses for a brief time to release

the pressure on it, and thus facilitate the manual release. The set value shows the length of the inversion. If=0

function disabled

• 000: facilitating release disabled

• >000: facilitation activated with release time equal to:

(0x25ms……………..20x25ms)

Margin adjustment of the opening stroke: adjusts the duration of the last stretch of the race during which any

obstacle is interpreted as a stroke, stopping the operator without executing the inversion. The value set indicates

the number of revolutions of the rotor.

1...................................255

Margin adjustment of the closing stroke: adjust the duration of the last stretch of the race during which any

obstacle is interpreted as a stroke, stopping the operator without executing the inversion. The value set indicates

the number of revolutions of the rotor.

1...................................255

Operators force adjustment at stroke arrival - If = 0, setting off (the force value on the stroke is calculated

automatically) - If ≠ 0, indicates the value (expressed in% of the max value ) of the force exerted on the stroke.

0%tot…...........................100%tot

“Energy saving” mode: If=1 after 10sec of inactivity, the control panel turns the 24V outputs and the display

off that will be turned on at first command received (use recommended battery-powered and / or solar panel).

• 000: “Energy saving” not active

• 001: “Energy saving” active

Electric-lock operating: if =0 electric-lock art. 110, if=1 24V output commanded by ELOCK_IN input in

impulsive mode, iF=2 24V output commanded by ELOCK_IN input in step-by-step mode, If>2 24V output

commanded by ELOCK_IN input in temporized mode (the set value indicates the delay of turning off expressed

in sec.

• 000: “Electric-lock art. 110 output

• 001: “24V d.c. max 5W Impulsive output

• 002: “24V d.c. max 5W Step-by-Step Output

• >002: “24V d.c. max 5W Temporized output

(3sec………………255sec)

Run direction inversion: If=1 automatically reverses the outputs open/close of the operators and any opening/

closing limit switches inputs, avoiding having to manual change the wiring when installing the operator in an

inverted position.

• 000: “Standard installation”

• 001: “Inverted installation”

Multiplier operations-counter: Multiply the number of operations after which the total operations-counter will

be updated.

To view the values, refer to the section “Visualisation of inputs and operations-counter status”.

• 000: “x100

• 001: “x1000

• 002: “x10000

• 003: “x100000

Maintenance Operations-counter: if = 0 reset the counter and disables the intervention request , if> 0 indicates

the number of operations (x 500) to be made before the control panel executes a 4 second additional pre-flash

to indicate the need of maintenance.

i.g.: If P064 = 050, operations number = 50x500 = 25000 operations

Warning: Before you set a new value of the counter-manoeuvres maintenance, the same must be reset by

setting P065= 0 and only later P065 = “new value”.

• 000: “Request Maintenance disabled

• >000: “Number of operations (x 500) for required

maintenance

Selection of operating flashing light output: If=0 intermittent flashing light output;

If=1 Fixed flashing light output (for flashing lights with intermittent interior circuits).

• 000: “intermittent flashing light output

• 001: “fixed flashing light output

Unused parameter

Unused parameter

Unused parameter

Unused parameter

Loading...

Loading...