DA2 Series Dehumidifier Owners Manual

Startup Compressor Oil Level

24 Dectron, Inc. November 2009

Data subject to change without notice.

Some units may not have oil-level sight-glasses in the side of the compressor(s). In this case, skip to the next

page.

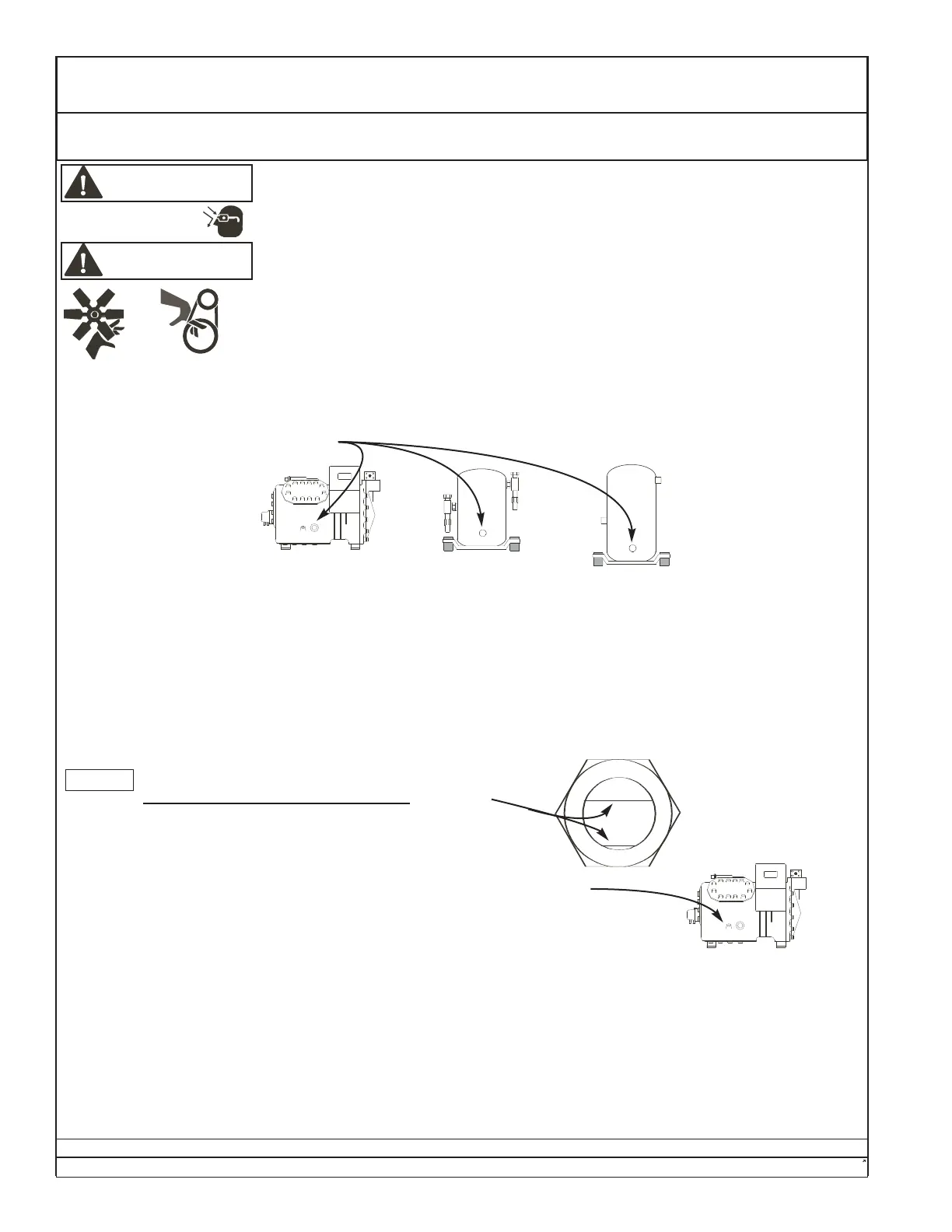

For units with oil-level sight glasses,

the oil level must be monitored carefully during the startup phase.

Check the oil level

1. 30 minutes after starting the compressor,

2. each hour for the four (4) hours after starting the compressor, and

3. before leaving for the day.

Add or remove oil to keep the level as near the middle of the sight glass as possible, and in any case between

1/8 and 3/4 full.

Risk of compressor damage.

DO

NOT OVERFILL OR UNDERFILL.

Risk of contact with moving parts. Can cause injury or death.

This product contains rotating parts and V-belt drives. Do not approach any moving

parts while electric power is applied to unit. Use only approved devices (e.g. locking

safety switch), to disconnect, lockout, and tagout all sources of electrical energy before

working inside the unit cabinet. Allow adequate time for rotating parts to stop. Follow

all applicable safety regulations.

WARNING

Samples

Actual appearances

may vary.

NOTICE

The oil may appear slightly foamy until 30 minutes after the expansion valve is properly adjusted. After the

expansion valve(s) is adjusted, the oil should not appear foamy. If the oil appears to be foaming after 30 minutes

of operation after the expansion valve is adjusted, contact Dectron.

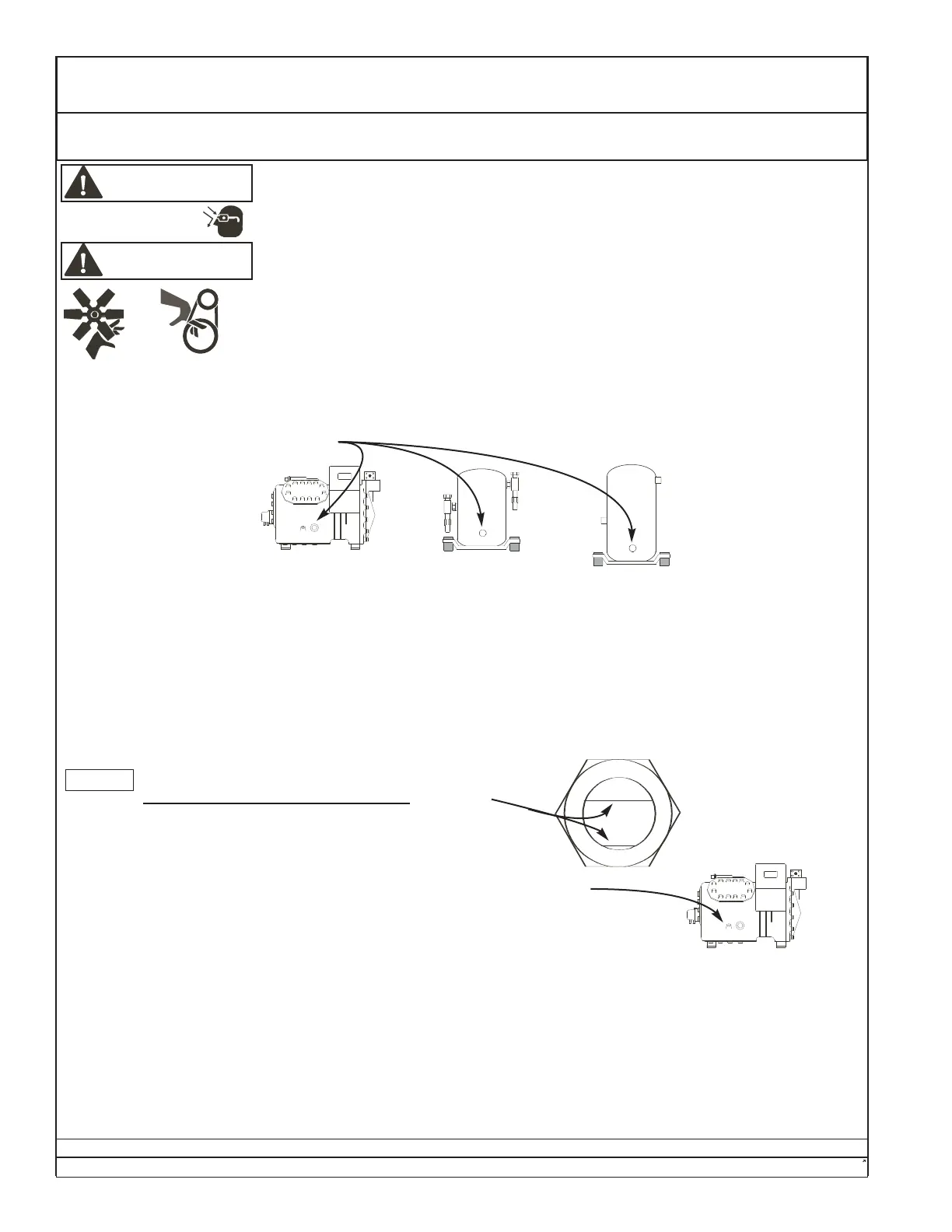

For semi-hermetic compressors, oil can be added through the oil fill plug.

Use standard procedures per compressor manufacturers.

For scroll compressors and hermetic reciprocator compressors, add oil through

the low-pressure convenience access valve, mounted on the unit cabinet.

Risk of flying liquids, gases, particles. Can cause eye injury.

This task may involve risk of exposure to flying materials which can cause eye

injury. Always wear protective safety glasses or goggles, as appropriate.

WARNING

Loading...

Loading...