DA2 Series Dehumidifier Owners Manual

Startup Adjust Expansion Valves

26 Dectron, Inc. November 2009

Data subject to change without notice.

Be sure that the blower overload device (if any) and the compressor(s) overload device(s), if any, are in the

RUN position. See Startup - Pre-Startup Adjustments.

Be sure the ENABLE switch is ON.

Some units may have a remote enable switch (by others) installed under

Installation - Wiring. In this case, be sure the switch is ON.

The blower should run unless

(a) the space temperature is less than 35°F (1.7°C), or

(b) the defrost timer is in defrost mode.

Defrost mode may last up to 10 minutes.

The compressor should run if the blower is running and if the humidistat set

point is less than the relative humidity of the air in the space.

If necessary, the humidistat set point can be reduced a little to cause the

compressor to run.

Carefully read and understand the warnings, cautions, and notices on the preceding page.

Be sure that the room temperature is between 40°F (4.4°C) and 80°F (27°C), or as shown on the unit

nameplate. (See Product Description - Unit Nameplate).

NOTICE

Risk of damage to equipment

The compressor should not be forced to run by reducing the

humidistat set point more than 10% below the set point

shown on the unit nameplate.

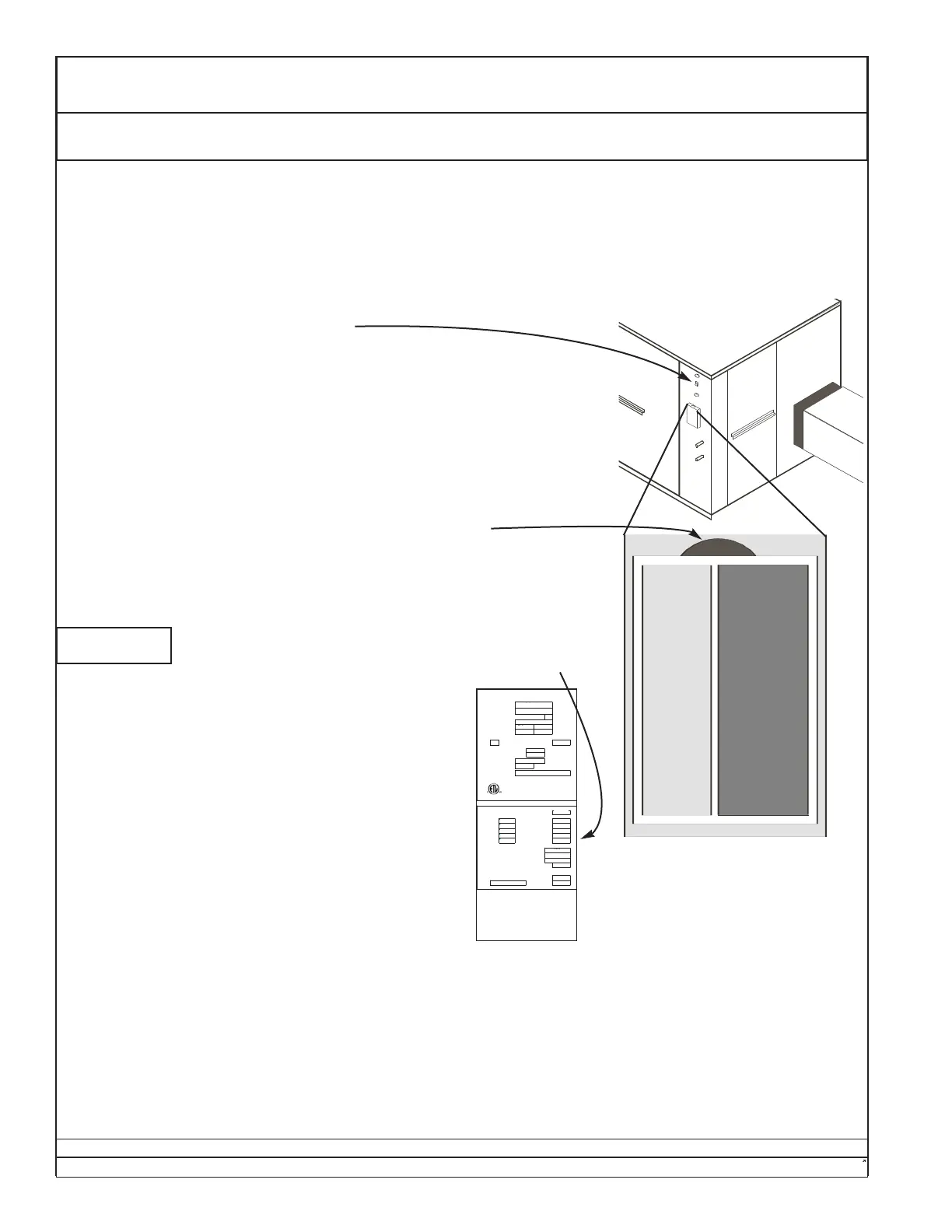

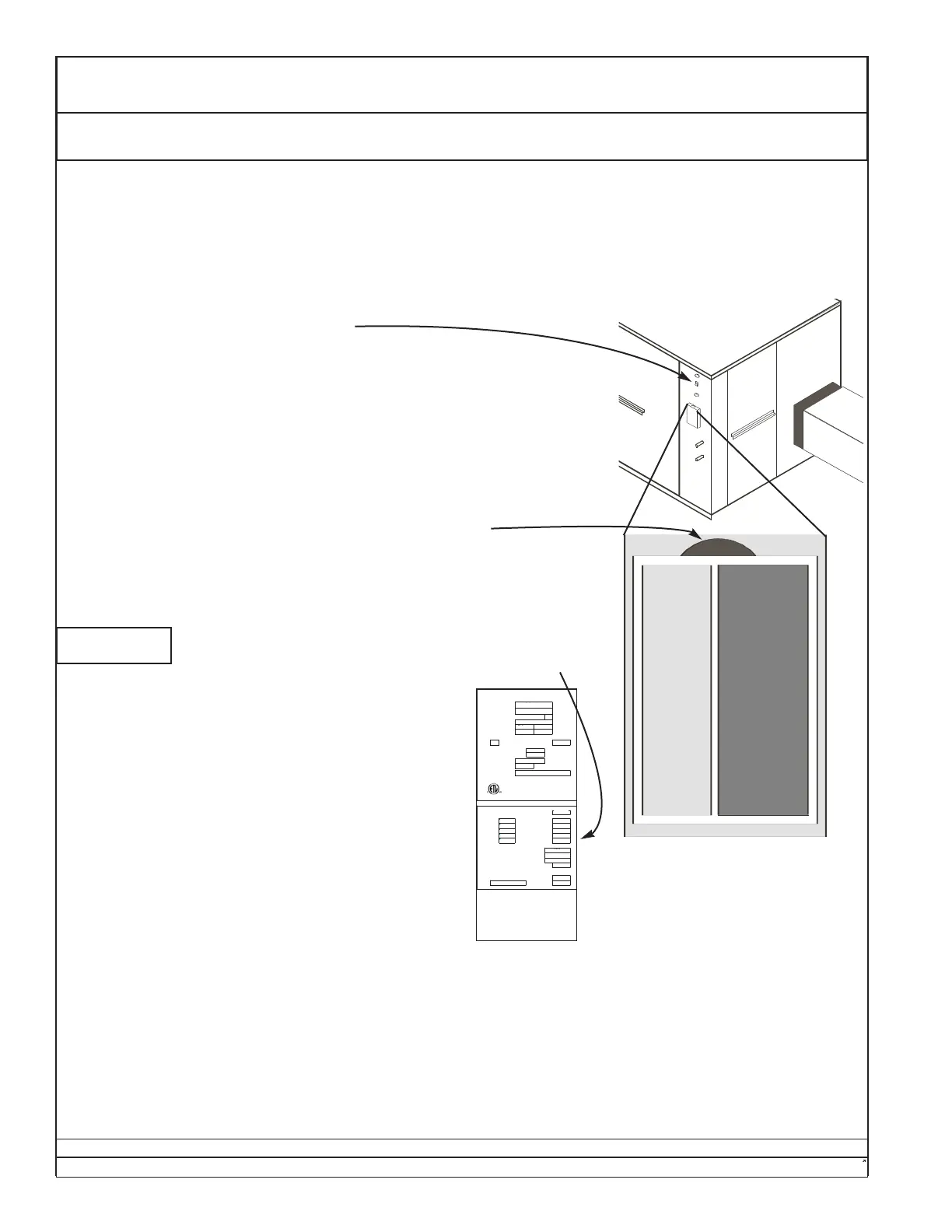

MODEL #: DA2-024-8

SERIAL #:

I.D.

T

575 V ac , 3 ph, 60 Hz

COMPRESSOR

50. 0

LRA

7.9

RLA

BLOW ER MOTOR

2

HP

2.4

FL A

MC A

13

A MAX. FUSE/CK T. BKR.

20

A

REFR IGERAN T TYPE

FACTORY CHARGE

15.5 lbs

AIR VO L U ME

3600 - 4000

CFM

BELT SIZE

WIRING DIAGRAM

DA2-W-024-021 AE Rev.5

REFRIGERANT DESIGN PRESS URES: HIGH/LOW 300 /150 PSIG

CERTIFIED TO STD CAN/CSA -

C22.2 NO. 236

FABRIQUÉ AU CANADA / MADE IN CANADA

POOL # 1: ft² POOL # 3: ft²

E.W.T.: ° F E.W.T.: °F

POOL # 2: ft² POOL # 4: ft²

E.W.T.: ° F E.W.T.: °F

AIR T E MP .:

60

°F R.H.:

60

%

R-22

15. 5

lbs

OIL T O BE ADDE D AT START- UP

oz

OIL TYPE

MAX. LENGTH OF REF. LINES (ONE WAY) ft

BETWEEN D.O.T. & REMOTE CONDENSER:

LINE S IZE:

AIR COOLED COND. MODEL #:

HOT GAS: i n

LIQUID: in

NOTE: In order to adjust the expansion valve

correctly, the space temperature and relative

humidity should be as near the normal conditions as

possible.

Samples

Actual appearances

may vary.

1. Continue to operate the unit for at least 20 minutes, monitoring the compressor-discharge temperature. Stop

operation if the discharge temperature exceeds 225°F (107°C).

2. After 20 minutes of compressor operation, and at least 10 minutes after the termination of any defrost cycle,

check the refrigerant sight glass.

If there are bubbles in the sight glass, slowly add the type of refrigerant shown on the unit nameplate until the

bubbles clear, then add one more pound by weight. NOTE: Do not add liquid refrigerant to a suction

access valve. If refrigerant has been added, return to step 1.

3. If the sight glass has been clear for at least 20 minutes, adjust the expansion valve(s) to cause the compressor

discharge temperature to agree with the charts on the following page.

Loading...

Loading...