Owners Manual DA2 Series Dehumidifier

Installation

Dectron, Inc. November 2009 9

Data subject to change without notice.

DECTRON

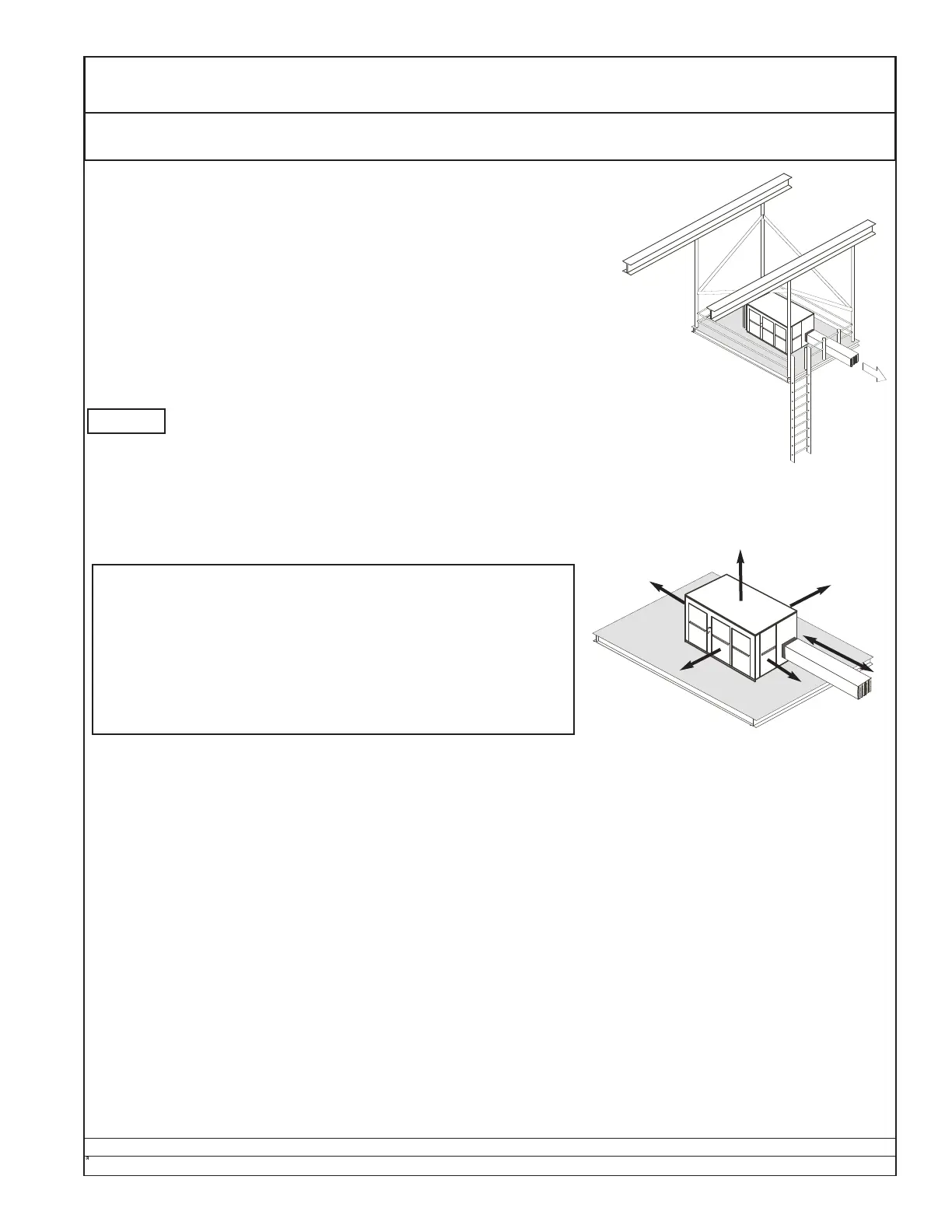

Minimum Service Access

a

ft (m)

1 2 3 4 5

DA2-007 - DA2-024 2 (0.6) 3

b

(1) 2 (0.6) 3 (1) 4 (1.2)

DA2-035 - DA2-070 3 (1) 3

b

(1) 3 (1) 3 (1) 4 (1.2)

a - access doors must be able to open to at least 90°.

b - (Canada) 1 meter

(USA) 3 ft for 230V, 3.5 ft for 460V units or per NEC

exhibit 110-26, whichever is greater.

4

2

3 ft. (1m)

3

1

5

Minimum clearances are required. See table below.

Sound and Vibration Elimination

Install anti-vibration springs or pads

such as machinery cork, rubber pads

or other approved isolation materials to

isolate the unit from the supporting

structure.

IMPORTANT!

Do not mount the unit on a ply-

wood sheet or any other material

that will resonate.

Install flexible duct to all duct connec-

tions of the unit to prevent sound and

vibration transmission. Use aerofoil-

type turning vanes on all elbows.

Elbows and acoustic insulation can be

used to further reduce noise where

necessary. See

Installation - Unit-

Duct Connections

.

Condensate Drain Connection

Some units may have bottom con-

densate drains connections. In this

case allow a minimum 12-inch clear-

ance for the bottom drain connection.

Some units may have side drains.

DA2 Series units have internal P-

traps and do not require others. Do

not install other P-traps without

consulting Dectron. Be sure to fill the

P-trap before starting the unit. Failure

to fill the P-trap will result in

condensate overflow.

Use schedule 40 PVC or standard

ABS plastic drainage pipe and slope

the condensate drain line at least 1/4

inch per foot. The drain line must dis-

charge through an air gap to a vented

open pipe.

If the unit is located below the drain

level a condensate pump is required

(available from Dectron with rated

maximum pump head of 9 feet and

shut-off pressure of 13 feet -- if higher

lift is required a more powerful pump

must be supplied by others). The

Dectron condensate pump and tank

comes complete with a high-level limit-

switch which must be connected to an

alarm. The alarm should notify person-

nel of a problem with condensate

removal.

If a condensate pump is used, it must

have sufficient pump head to over-

come vertical lift and water pressure if

pumped into a pressurized pipeline.

When connecting to a pressurized

pipeline, a check valve and normally-

closed solenoid valve should be uti-

lized in the condensate pump dis-

charge line, with the valve only open-

ing during pump operation. Do not

connect the condensate drain to a

pipe with negative pressure.

Air filters and blower belts require regular maintenance. Should it become necessary, major-

component replacement may require some minimum working clearance.

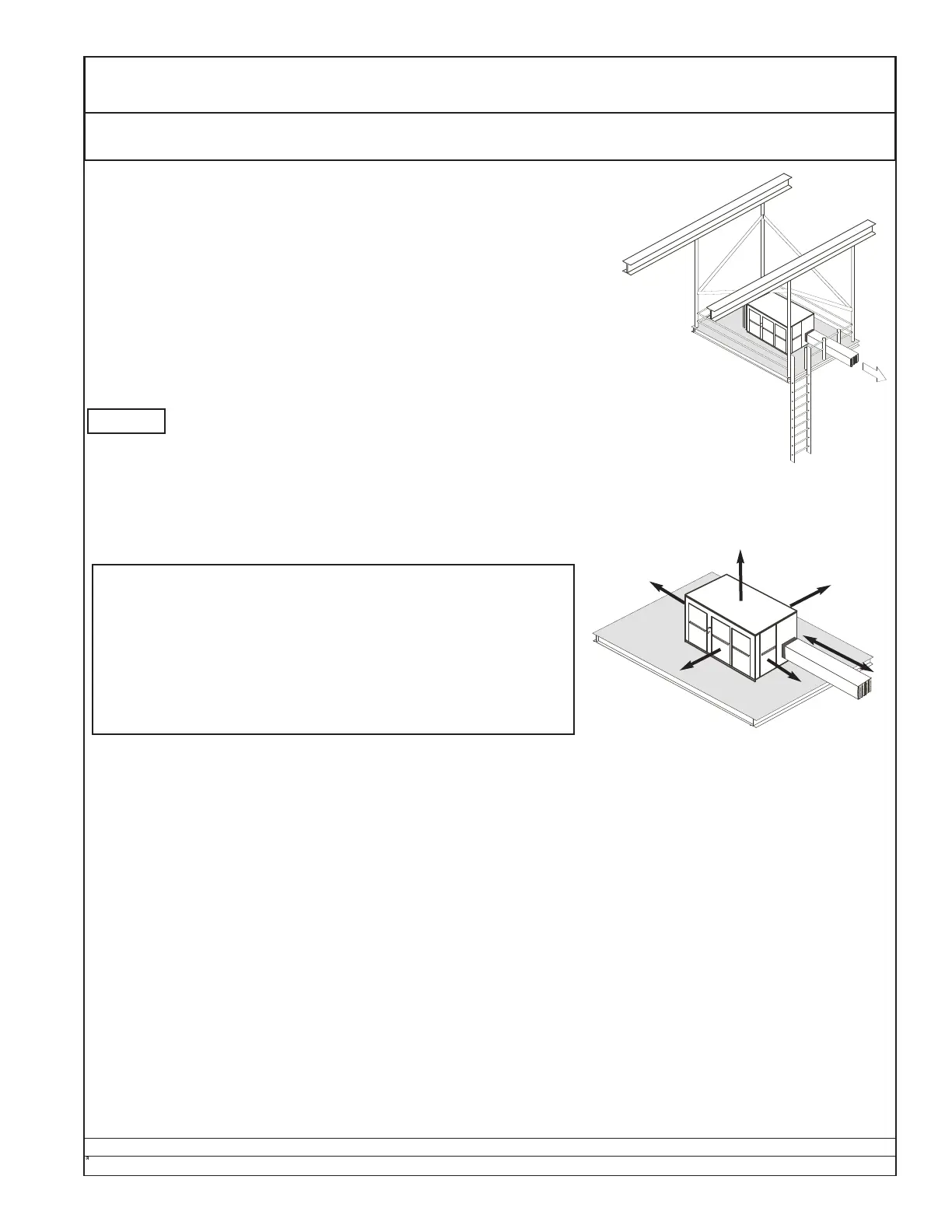

If the air handler unit is located overhead, then:

1. Adequate and safe service and maintenance access must be provided.

2. A mezzanine floor must be constructed to allow the minimum service

access.

3. Where the units are mounted above the floor level, adequate fall-protection rails

should be provided.

4. Minimum straight lengths of duct may be required. See Installation - Ducting.

5. Provision must be made for disposal of condensate.

NOTICE

Safety switches, safety valves, fall protection, pipes, conduits, etc., are not shown here.

This diagram is for illustration only, and is not suitable for any particular purpose. A

qualified structural engineer should design any support system, including fall protection.

Loading...

Loading...