^F

77

!

fnW\

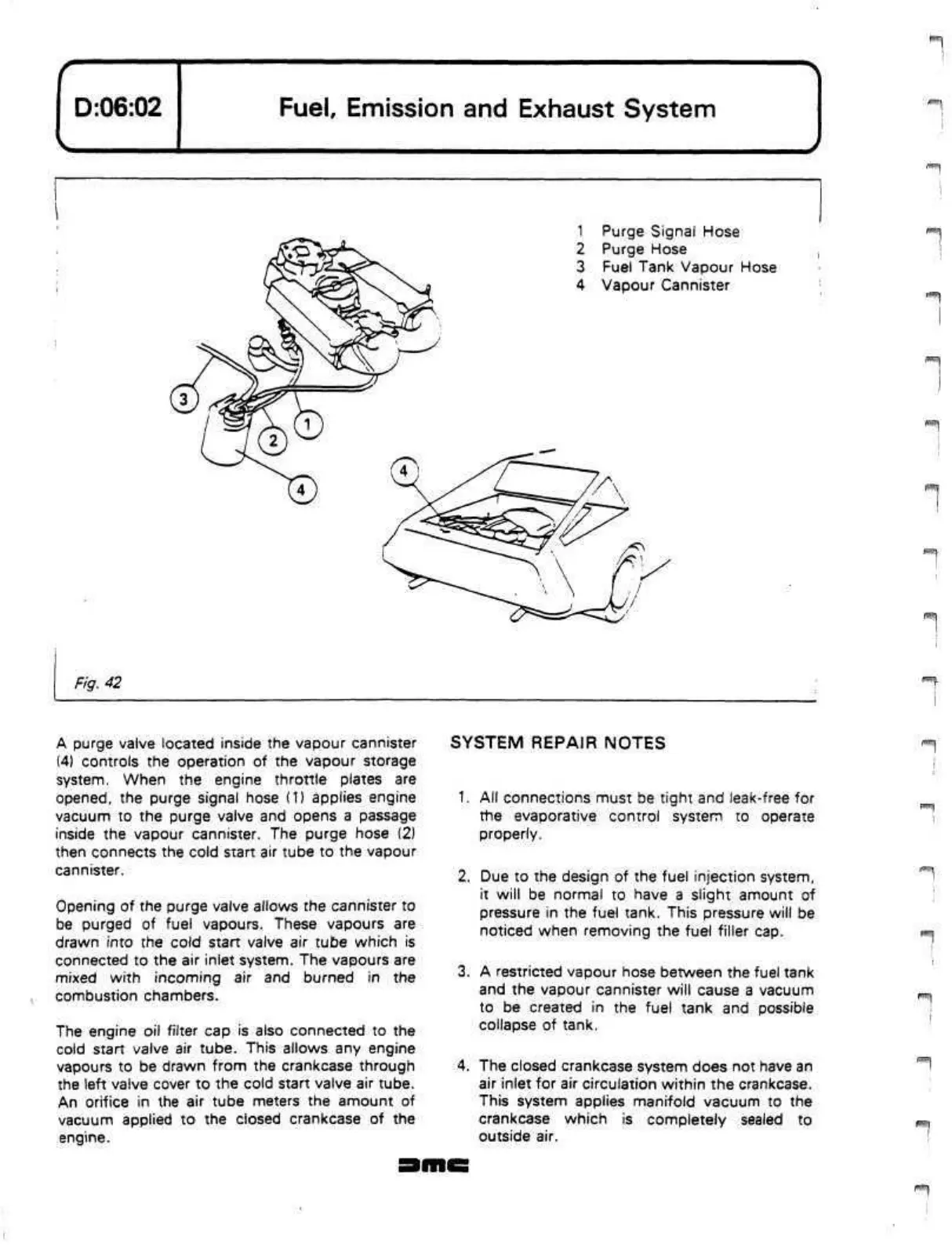

1 Purge Signal Hose

2 Purge Hose

3 Fuel Tank Vapour Hose

4 Vapour Cannister

^•••''r

Fig.

42

A purge valve located inside the vapour cannister

(4) controls the operation of the vapour storage

system.

When the engine throttle plates are

opened,

the purge signal hose (1) applies engine

vacuum to the purge valve and opens a passage

inside the vapour cannister. The purge hose (2)

then connects the cold start air tube to the vapour

cannister.

Opening of the purge valve allows the cannister to

be purged of fuel vapours. These vapours are

drawn into the cold start valve air tube which is

connected to the air inlet system. The vapours are

mixed with incoming air and burned in the

combustion chambers.

The engine oil filter cap is also connected to the

cold start valve air tube. This allows any engine

vapours to be drawn from the crankcase through

the left valve cover to the cold start valve air tube.

An orifice in the air tube meters the amount of

vacuum applied to the closed crankcase of the

engine.

SYSTEM REPAIR NOTES

1.

All connections must be tight and leak-free for

the evaporative control system to operate

properly.

2.

Due to the design of the fuel injection system,

it will be normal to have a slight amount of

pressure in the fuel tank. This pressure will be

noticed when removing the fuel filler cap.

3. A restricted vapour hose between the fuel tank

and the vapour cannister will cause a vacuum

to be created in the fuel tank and possible

collapse of tank.

4.

The closed crankcase system does not have an

air inlet for air circulation within the crankcase.

This system applies manifold vacuum to the

crankcase which is completely sealed to

outside air.

Loading...

Loading...