Rear Suspension

K.08.01

TOE-IN ALIGNMENT ADJUSTMENT

1.

Check rear wheels for rim run out. Maximum

tolerance is .406 mm (.16 inch).

2.

Check tyre pressures. 30 p.s.i. 2.06 bar.

3. Check and ensure no abnormal wear in

suspension, joints, wheel bearings.

4.

Place

vehicle

on flat surface.

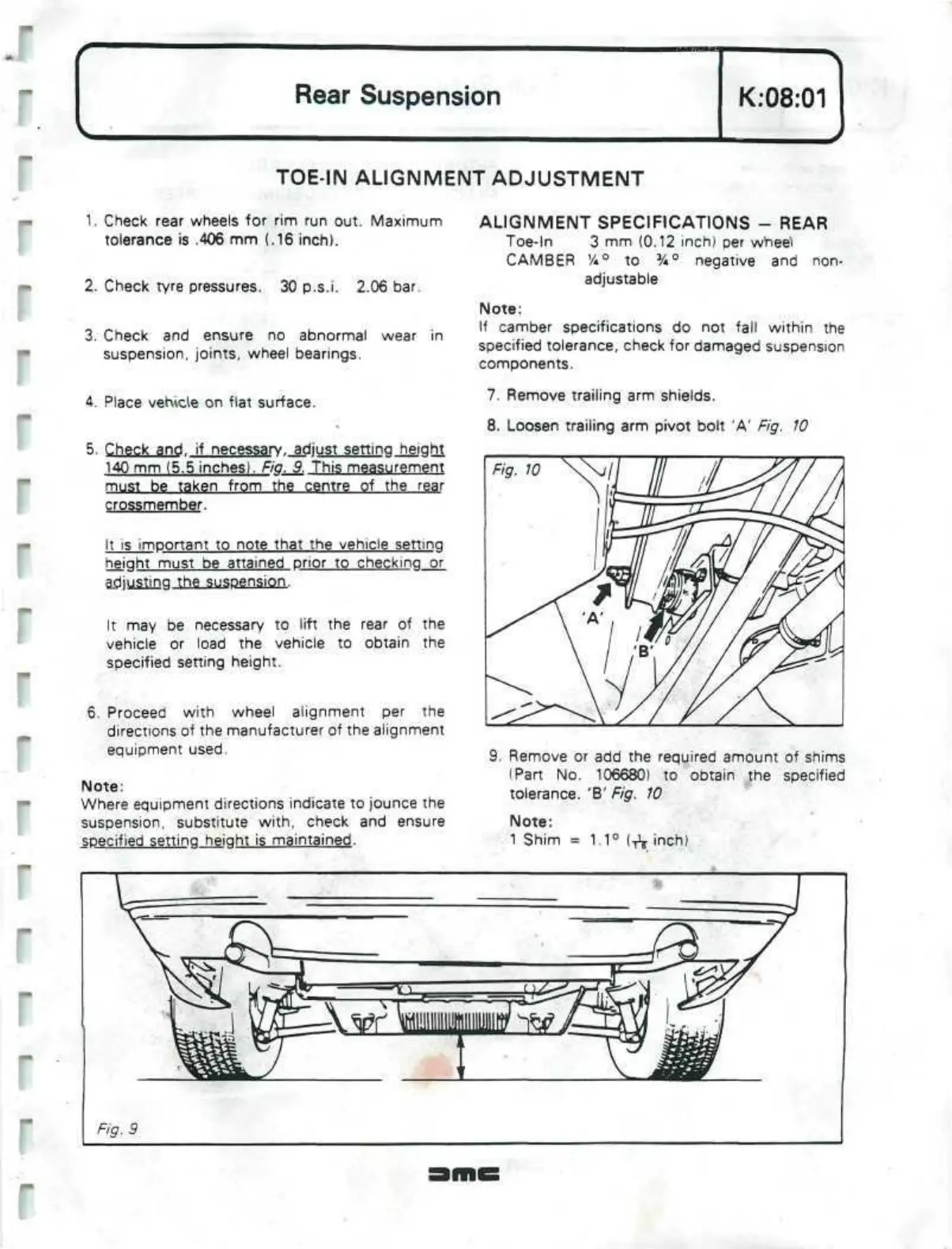

5. Check and, if necessary, adjust setting height

140 mm (5.5 inches). Fig. 9. This measurement

must be taken from the centre of the rear

crossmember.

It is important to note that the vehicle setting

height must be attained prior to checking or

adjusting the suspension.

It may be necessary to lift the rear of the

vehicle or load the vehicle to obtain the

specified setting height.

6. Proceed with wheel alignment per the

directions of the manufacturer of the alignment

equipment used.

Note:

Where equipment directions indicate to jounce the

suspension, substitute

with,

check and ensure

specified setting height is maintained.

ALIGNMENT SPECIFICATIONS - REAR

Toe-In

3 mm (0.12 inch) per

whee^

CAMBER

V*°

to

3

/4°

negative and non-

adjustable

Note:

If

camber specifications do not fall within the

specified tolerance, check for damaged suspension

components.

7. Remove trailing arm shields.

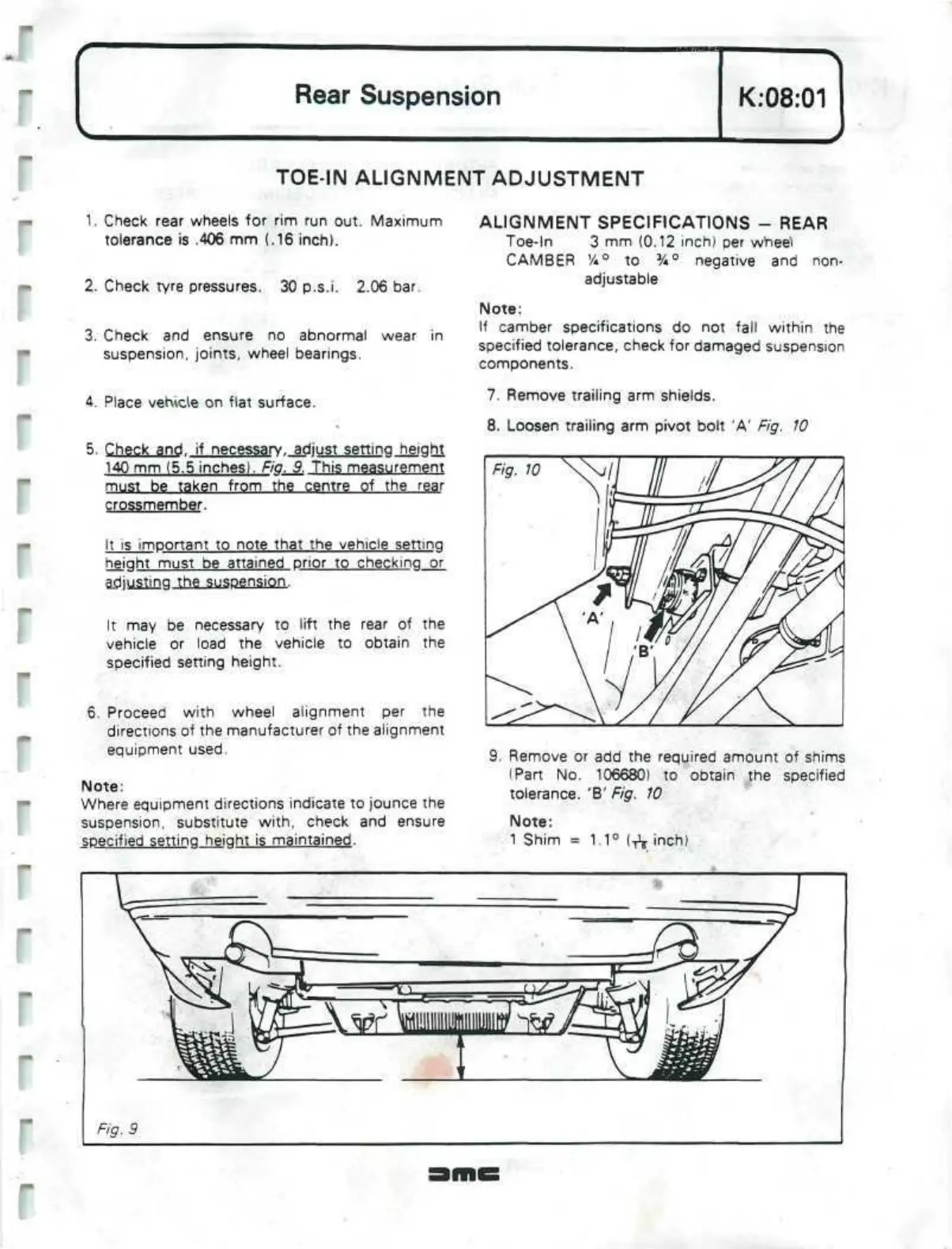

8. Loosen trailing arm pivot bolt 'A' Fig. 10

9. Remove or add the required amount of shims

(Part No. 106680) to obtain the specified

tolerance. 'B' Fig. 10

Note:

1 Shim = 1.1°

(-fi

inch)

'

Loading...

Loading...