M:04:04

7. Remove the nuts, washers and through bolts

(15).

8. Separate the drive end bracket (8) from the

stator

(7),

slip ring end bracket (6) and rotor

assembly (16). Withdraw the stator (7) from

the slip ring end bracket (6).

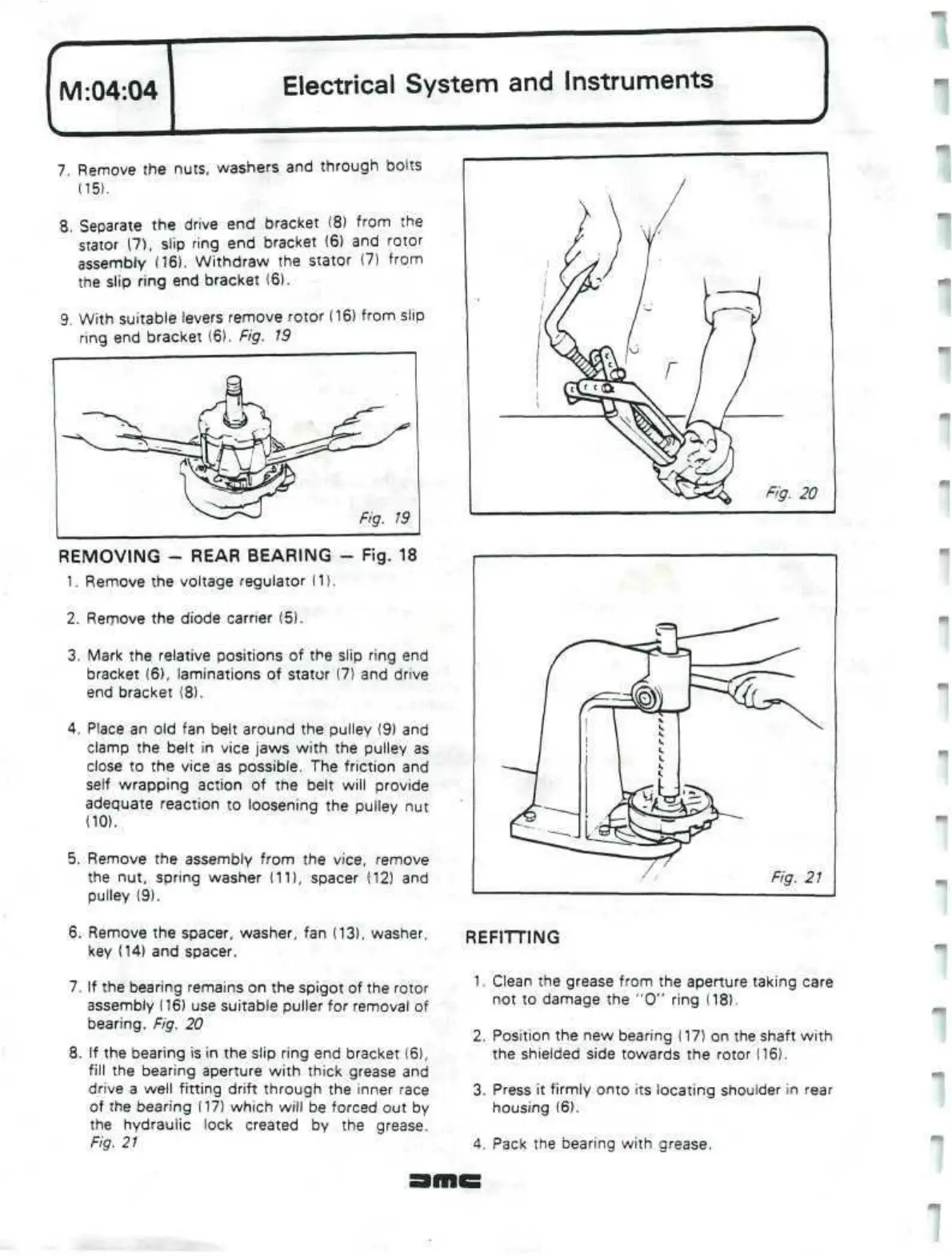

9. With suitable levers remove rotor (16) from slip

ring end bracket (6). Fig.

19

REMOVING

-

REAR BEARING - Fig. 18

1.

Remove the voltage regulator (1).

2.

Remove the diode carrier (5).

3. Mark the relative positions of the slip ring end

bracket (6), laminations of stator (7) and drive

end bracket (8).

4.

Place an old fan belt around the pulley (9) and

clamp the belt in vice jaws with the pulley as

close to the vice as possible. The friction and

self wrapping action of the belt will provide

adequate reaction to loosening the pulley nut

(10).

5. Remove the assembly from the vice, remove

the nut, spring washer (11), spacer (12) and

pulley (9).

6. Remove the spacer, washer, fan (13), washer,

key (14) and spacer.

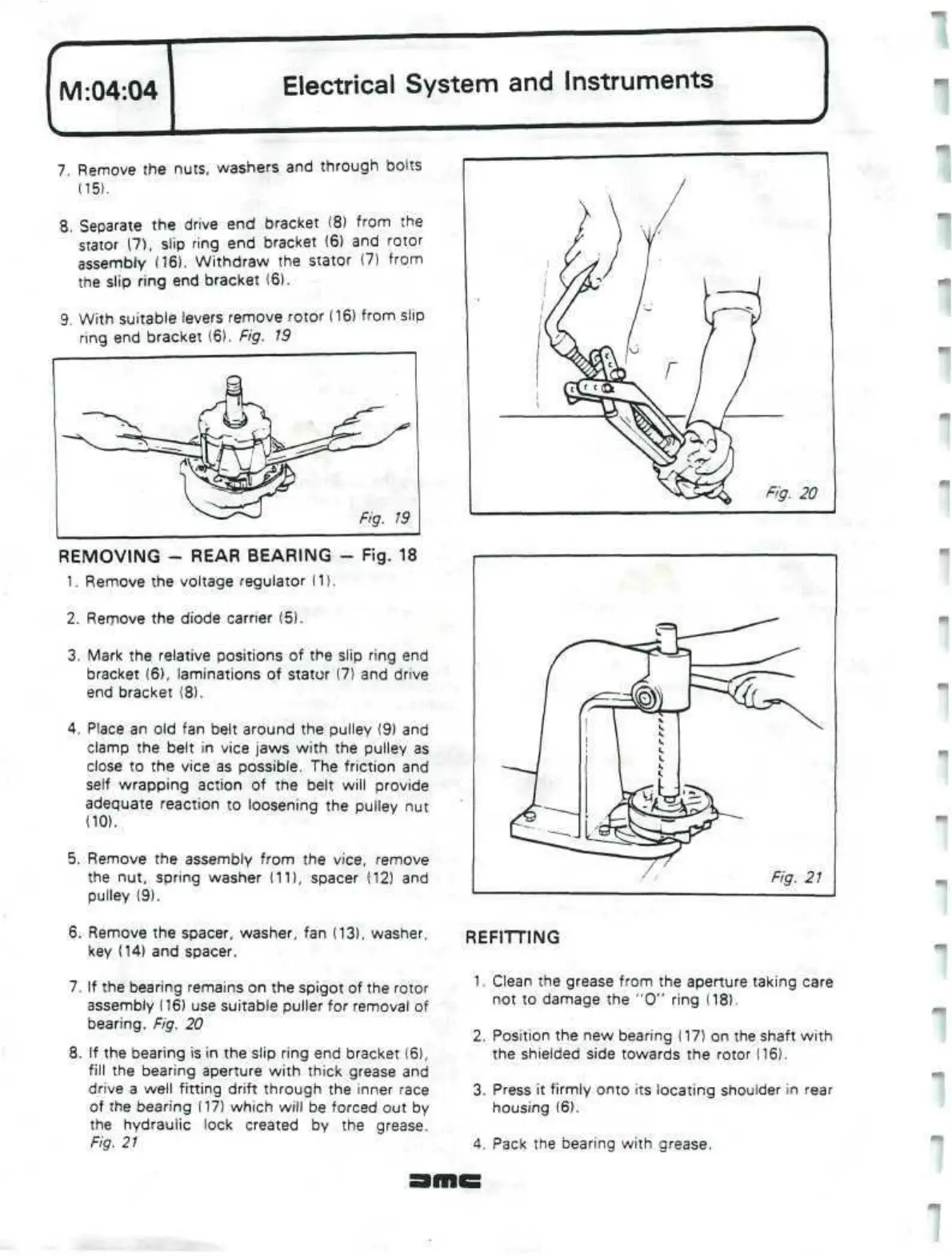

7. If the bearing remains on the spigot of the rotor

assembly (16) use suitable puller for removal of

bearing.

Fig. 20

8.

If

the bearing is in the slip ring end bracket (6),

fill the bearing aperture with thick grease and

drive a well fitting drift through the inner race

of the bearing (17) which will be forced out by

the hydraulic lock created by the grease.

Fig.

21

REFITTING

1.

Clean the grease from the aperture taking care

not to damage the "0" ring (18).

2.

Position the new bearing (17) on the shaft with

the shielded side towards the rotor (16).

3. Press it firmly onto its locating shoulder in rear

housing (6).

4.

Pack the bearing with grease.

1

Loading...

Loading...