N

.03:02

Heating and Air Conditioning

COMPONENT DESCRIPTION

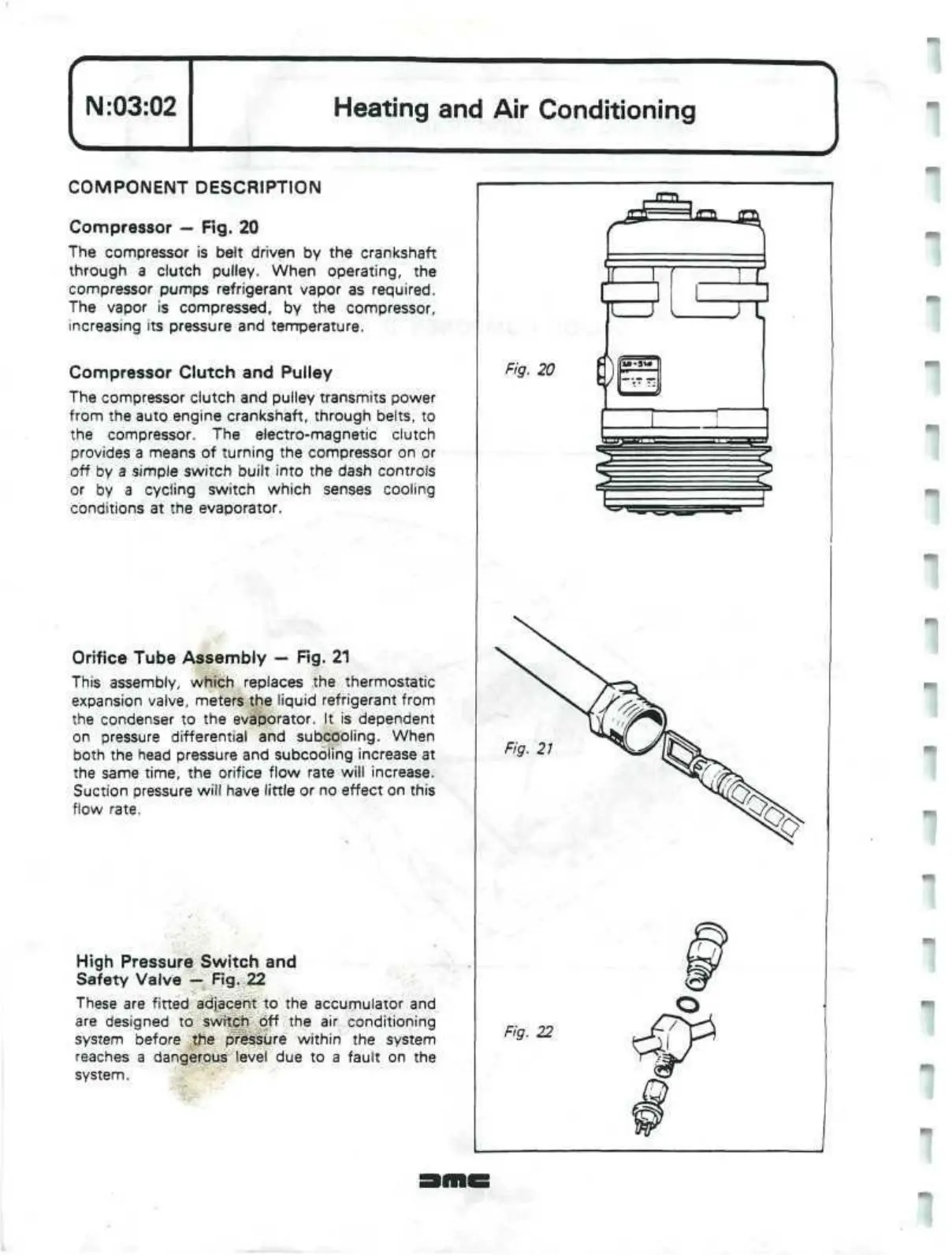

Compressor — Fig. 20

The compressor is belt driven by the crankshaft

through a clutch pulley. When operating, the

compressor pumps refrigerant vapor as required.

The vapor is compressed, by the compressor,

increasing its pressure and temperature.

Compressor Clutch and Pulley

The compressor clutch and pulley transmits power

from the auto engine crankshaft, through belts, to

the compressor. The electro-magnetic clutch

provides a means of turning the compressor on or

off by a simple switch built into the dash controls

or by a cycling switch which senses cooling

conditions at the evaporator.

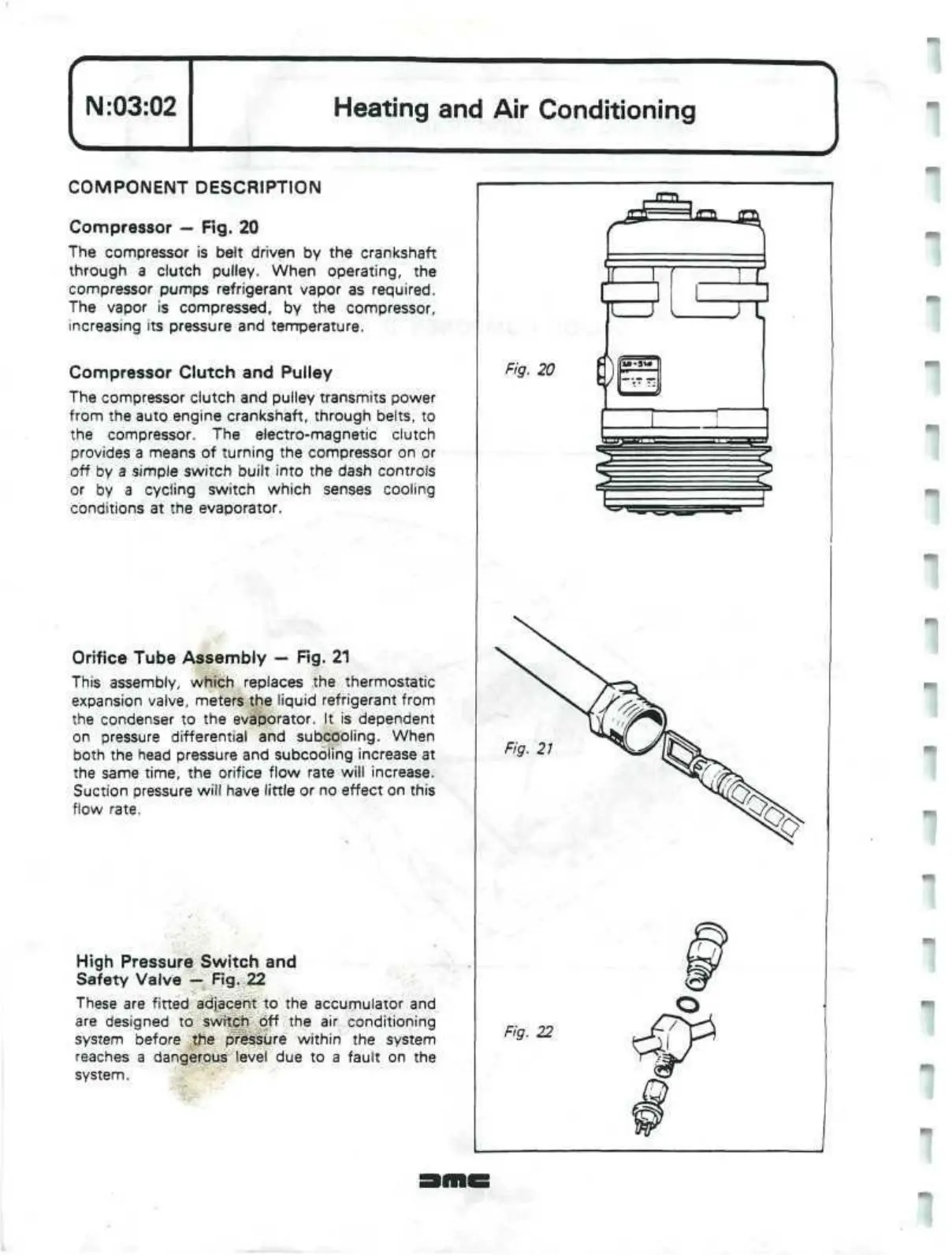

Orifice Tube Assembly —

Rg.

21

This assembly, which replaces the thermostatic

expansion valve, meters the liquid refrigerant from

the condenser to the evaporator. It is dependent

on pressure differential and subcooling. When

both the head pressure and subcooling increase at

the same time, the orifice flow rate will increase.

Suction pressure will have little or no effect on this

flow rate.

High Pressure Switch and

Safety Valve —

Fig.

22

These are fitted adjacent to the accumulator and

are designed to switch off the air conditioning

system before the pressure within the system

reaches a dangerous level due to a fault on the

system.

Fig. 20

Fig.

21

Fig. 22

Loading...

Loading...