Fuel,

Emission and Exhaust System

D:01:07

p

5

*!

pw^

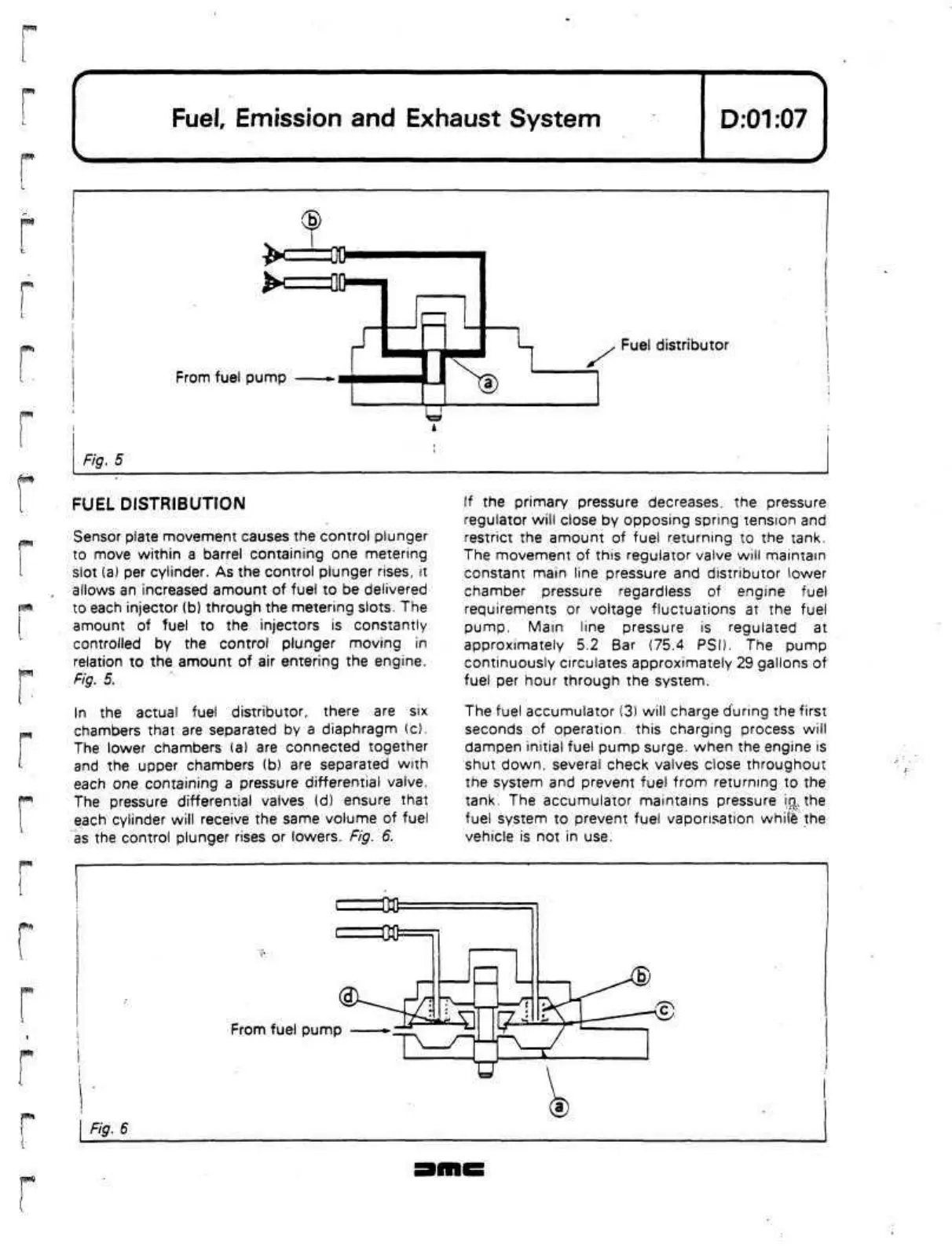

From fuel pump

Fig. 5

Fuel distributor

r

FUEL DISTRIBUTION

Sensor plate movement causes the control plunger

to move within a barrel containing one metering

slot (a) per cylinder. As the control plunger rises,

it

allows an increased amount of fuel to be delivered

to each injector (b) through the metering slots. The

amount of fuel to the injectors is constantly

controlled by the control plunger moving in

relation to the amount of air entering the engine.

Fig. 5.

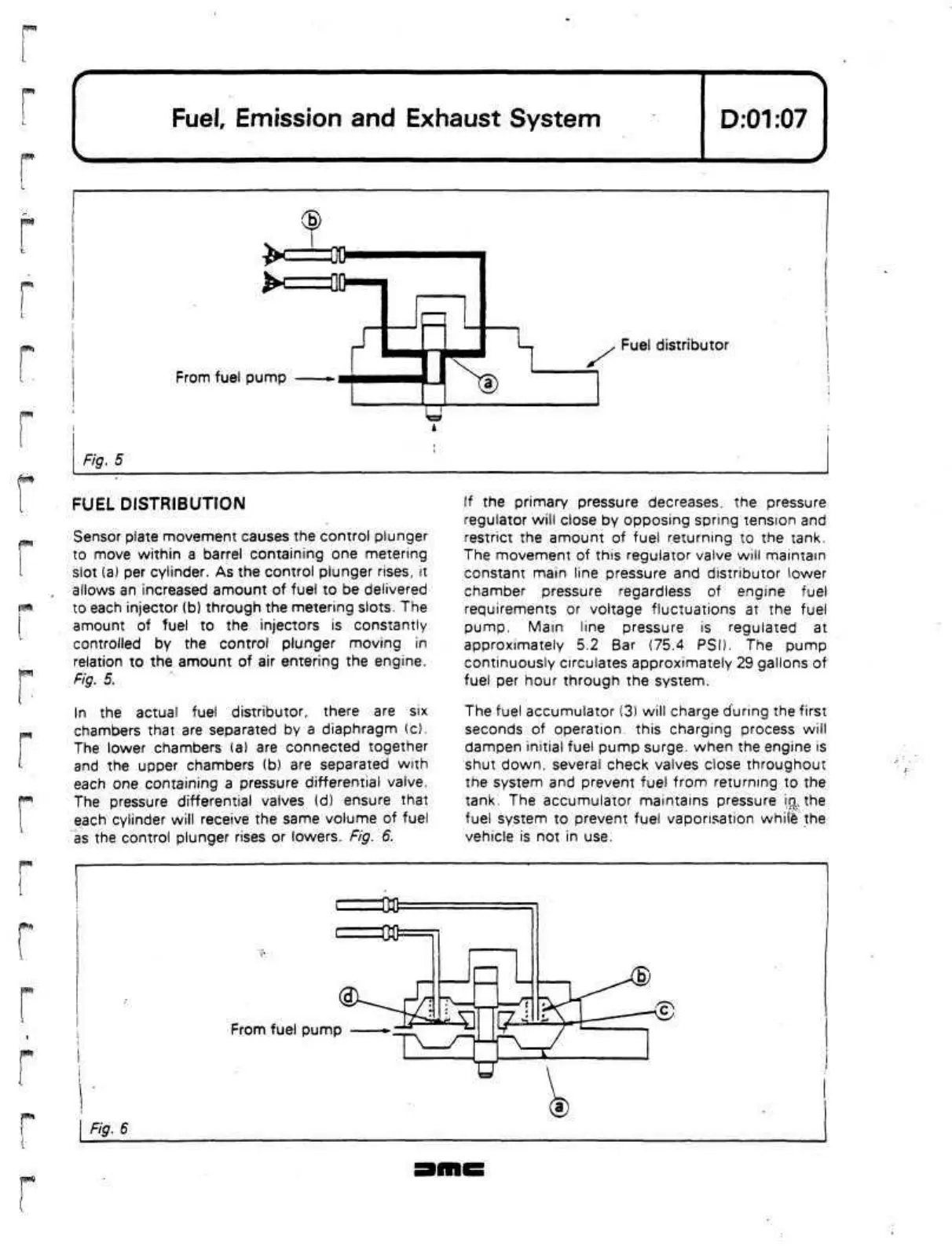

In

the actual fuel distributor, there are six

chambers that are separated by a diaphragm (c).

The lower chambers (a) are connected together

and the upper chambers (b) are separated with

each one containing a pressure differential valve.

The pressure differential valves

(d)

ensure that

each cylinder will receive the same volume of fuel

as the control plunger rises or lowers. Fig. 6.

If

the primary pressure decreases, the pressure

regulator will close by opposing spring tension and

restrict the amount of fuel returning to the tank.

The movement of this regulator valve will maintain

constant main line pressure and distributor lower

chamber pressure regardless of engine fuel

requirements or voltage fluctuations at the fuel

pump.

Main

line pressure is regulated at

approximately 5.2 Bar (75.4 PSD. The pump

continuously circulates approximately 29 gallons

of

fuel per hour through the system.

The fuel accumulator (3) will charge during the first

seconds of

operation,

this charging process will

dampen initial fuel pump

surge,

when the engine is

shut

down,

several check valves close throughout

the system and prevent fuel from returning to the

tank. The accumulator maintains pressure

ifjLthe

fuel system to prevent fuel vaporisation

white*

the

vehicle is not in use.

From fuel pump

Fig. 6

Loading...

Loading...