English-4

Basic Inspection

Item Content

General Inspection

Periodically inspect the screws of the connection between the HMI and

device. Tighten screws as necessary as they may loosen due to vibration

and varying temperatures.

Ensure that oil, water, metallic particles or any foreign objects do not fall

inside the HMI, control panel or ventilation slots and holes. As these will

cause damage.

Ensure the correct installation and the control panel. It should be free from

airborne dust, harmful gases or liquids.

Inspection before

operation (power is

not applied)

Ensure that all wiring terminals are correctly insulated.

Ensure that all wiring is correct or damage and or malfunction may result.

Visually check to ensure that there are not any unused screws, metal strips,

any conductive or inflammable materials inside HMI.

Ensure to lower electromagnetic interference when devices are influenced

by it.

Ensure that the external applied voltage to HMI is correct and matched to the

controller.

Inspection before

operation (power is

applied)

Check if power LED lights.

Check if the communication among devices is normal.

Please contact your local Delta sales representative if there are any

abnormal conditions.

Pin Definition of Serial Communication

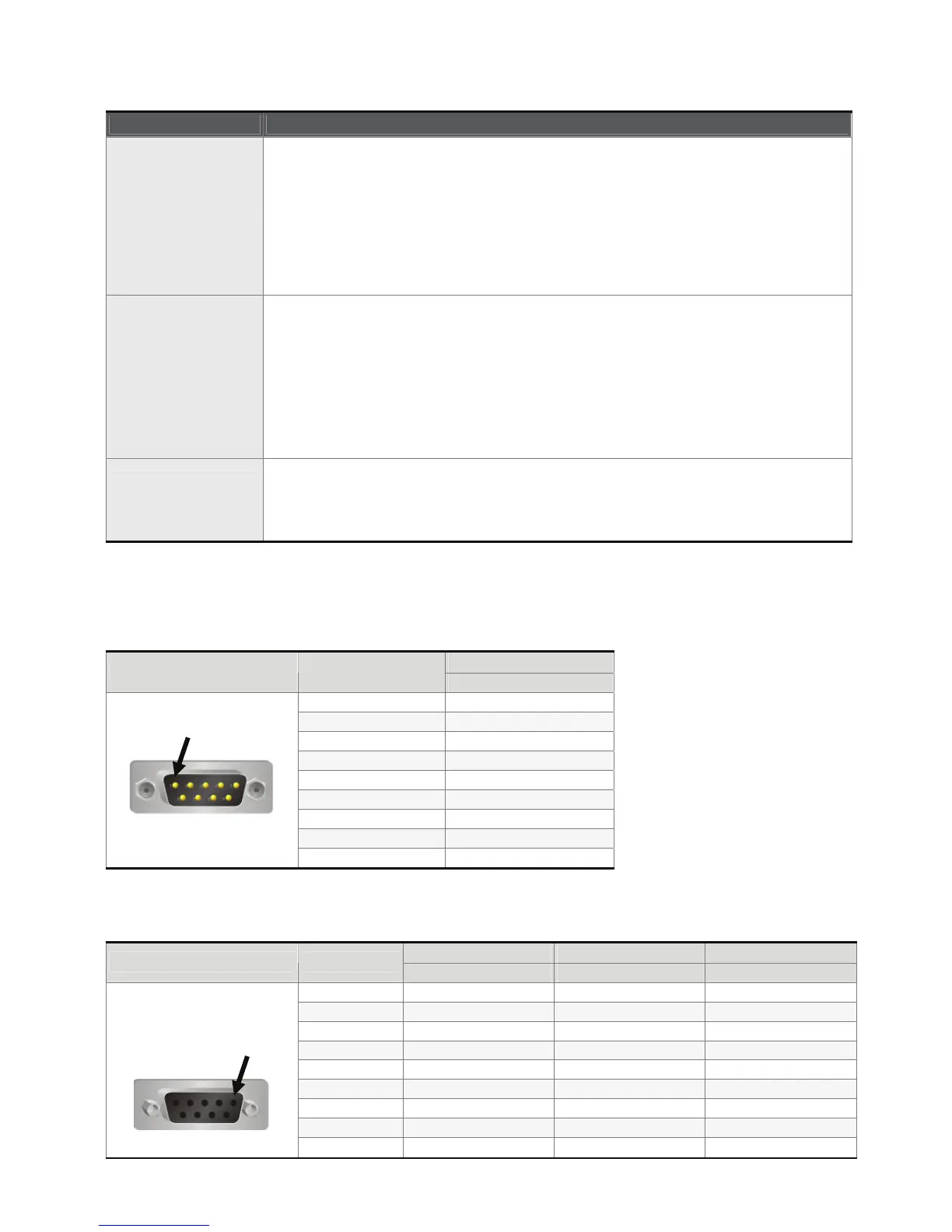

COM1 Port (Supports Flow Control)

Contact

COM Port PIN

RS-232

1

2 RXD

3 TXD

4

5 GND

6

7 RTS

8 CTS

9

Note: Blank = No Connection.

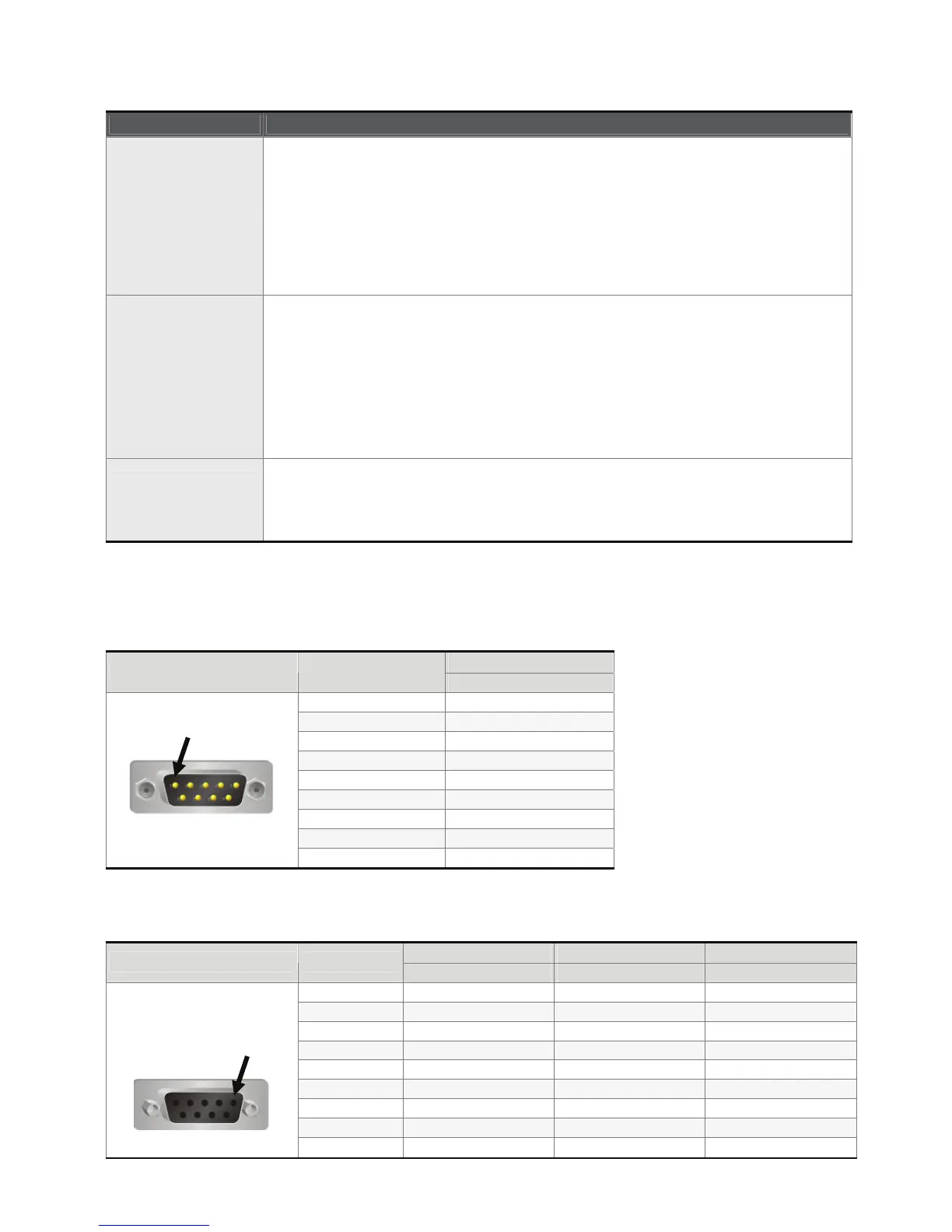

COM2 Port (Supports Flow Control)

MODE1 MODE2 MODE3

COM Port PIN

RS-232 RS-422 RS-485

1 TXD+ D+

2 RXD

3 TXD

4 RXD+

5 GND GND GND

6 TXD- D-

7 RTS

8 CTS

9 RXD-

PIN1

PIN1

Loading...

Loading...