16

6.4 AC and DC Cabling Instructions

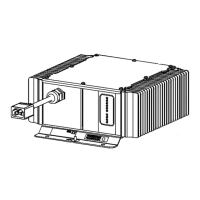

AC and DC cabling for the IC650 Charger can be completely customized by the customer. Cables can

easily be attached into the sealed DC block and the IEC320 AC receptacle.

The modular design of the IC650 Charger has several benefits:

Customers only have to manage a single SKU for each power level (e.g. 24V / 36V / 48V).

Units can be customized by the customer at their factory based on demand for specific DC

connectors or AC cords for different countries.

AC and DC cables are field replaceable, saving the time and expense of sending units for repair.

When supplied with cables, field technicians can test and operate the charger in only a few

minutes.

DC Cabling Installation Instructions

To attach DC cabling to the IC650 Charger, you

will need the following items:

1 - Torx T30 screwdriver

1 - Torx T10 screwdriver

2 - Torx T30 / M6 screws

2 - Torx T10 screws

1 - DC cable with ring terminals for

attachment into the DC block

1 - Delta-Q IC650 DC block cover (part no.

_____)

1 - Delta-Q IC650 DC cable clamp (part no.

_____)

1. Remove the DC block cover.

2. Attach the DC cable clamp over the DC cable,

then attach positive and negative leads from the

DC cable to the positive and negative terminals

inside the DC block. Reattach the DC block cover.

Figure 16. Remove the DC block cover by inserting

the head of the Torx T30 screwdriver into the gap

on the lower left side of the DC block xture, and

apply pressure to trigger the cover’s release. It can be

removed and put aside.

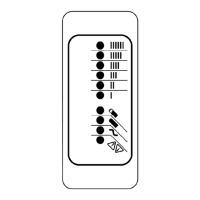

Figure 17. Fix the DC cable in place using the Delta-Q

cable clamp, fastened with Torx T10 screws to a

recommended torque of 0.6Nm +/-6%. Proceed by

attaching the positive and negative leads to the

positive and negative terminals, respectively, using

the Torx T30 screwdriver and Torx T30 / M6 screws,

with a recommended torque of 4.5Nm +/-5%.

Loading...

Loading...