TROUBLESHOOTING

Only qualified personnel should work on electrical equipment. Working on or

near energized equipment could result in death or serious injury.

1. If the fan fails to start, consult wiring diagram to ensure proper connection.

2. Check the incoming supply for proper voltage.

3. Verify that pressure switch diaphragm is vertical and tubing is not crimped.

4. Remove the probe from duct, clear any obstructions and blow gently into it. Reconnect probe.

5. If fan fails to start, lock electrical service to the fan in the “OFF” position.

6. Remove pressure switch. Use a meter to test for continuity across the fan motor leads.

7. Connect the incoming power supply directly to the fan motor. Turn on power to fan.

8. If fan fails to start, please contact factory.

RECOMMENDED MAINTENANCE

Disconnect and lock out power supply before performing any maintenance.

Working on or near energized equipment could result in death or serious injury.

1. Fan bearings are sealed. No additional lubrication is necessary.

2. Periodic inspection, based upon usage, should be performed to ensure that the fan impeller is

not obstructed. The fan should be inspected a minimum of every six (6) months.

3. Excessive fan noise or vibration may indicate an obstructed impeller.

4. To inspect and clean impeller:

a) Remove the duct from the fan inlet and remove any obstruction from the impeller.

b) Reconnect the duct to the fan.

c) Turn power supply on.

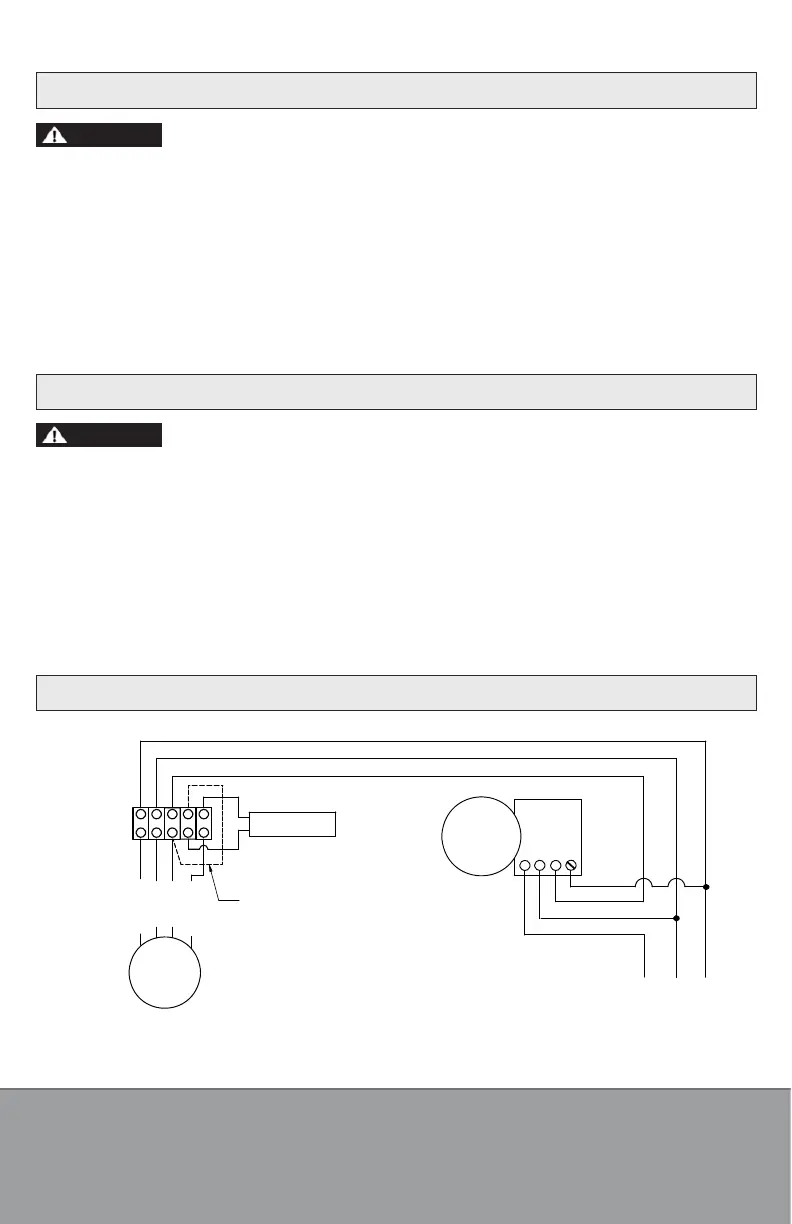

WIRING DIAGRAM

1

2

3

GREEN

WHITE

RED

PRESSURE

SWITCH

BLACK

WHITE

GREEN

RED

BLACK

WHITE

GREEN

117 VOLT SUPPLY

FROM FUSE PANE

NOTE: JUMPER MUST BE USED WHEN MOTOR

IS OPERATED WITH PRESSURE SWITCH

GREEN

WHITE

RED

CAPACITOR

ERMINAL

BLOCK

BROWN

BLACK

BLUE

YELLOW

FAN

MOTOR

WHITE JUMPER

DVK-P-I&M-1706

1-800-779-4021 • www.continentalfan.com

Continental Fan Manufacturing Inc.

203 Eggert Road

Bualo, New York 14215

Continental Fan Manufacturing Inc.

6274 Executive Blvd.

Dayton, Ohio 45424

Continental Fan Canada Inc.

12-205 Matheson Blvd E

Mississauga, Ontario L4Z 3E3

Loading...

Loading...