19

English

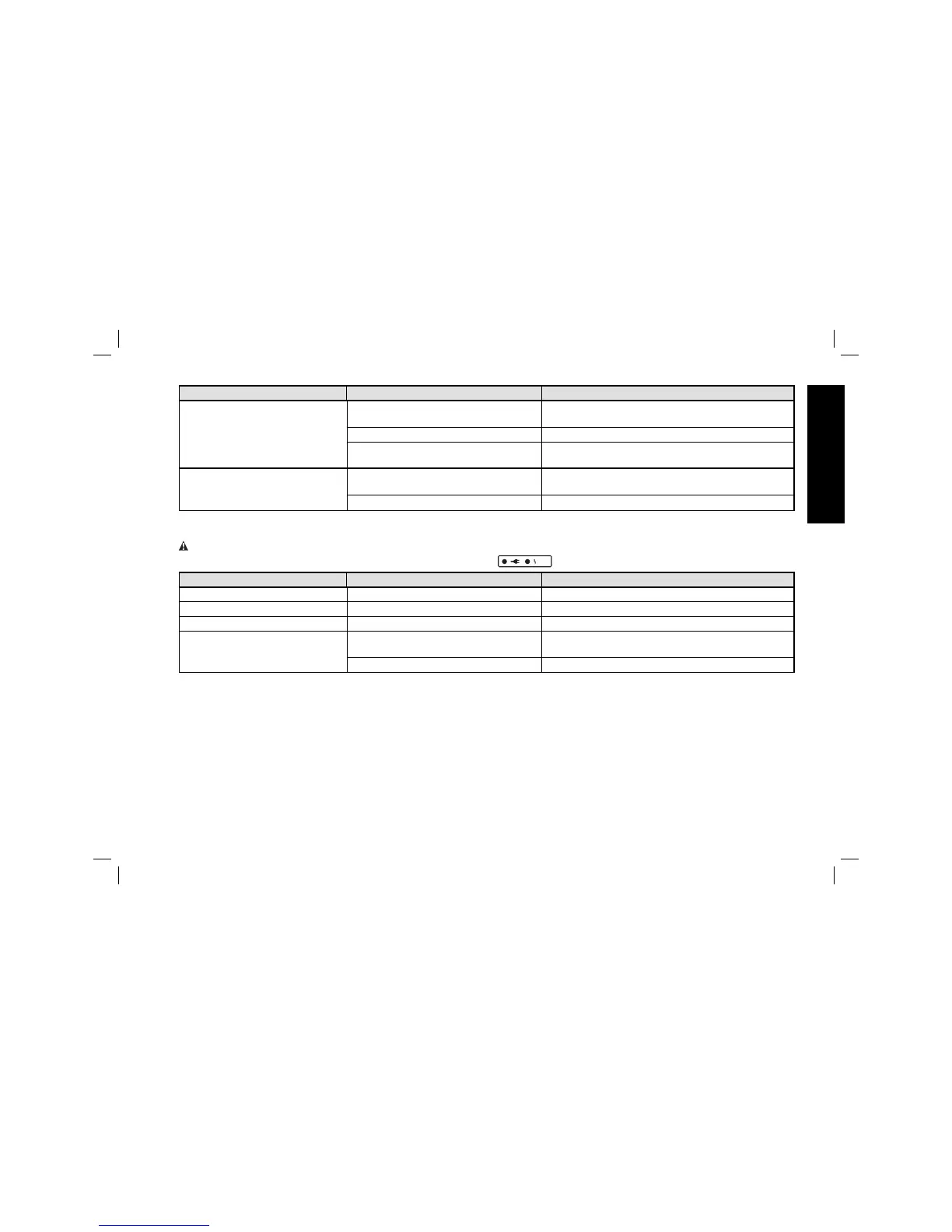

SYMPTOM CAUSE FIX

Poor weld properties

(severe spattering)

Incorrect electrode polarity. Reverse electrode polarity (refer to manufacturer's

instructions).

Poor grounding (earthing) connection. Fasten earthing clamps directly to workpiece.

Set-up parameters not ideal for selected

welding process.

Select best setting in set-up menu for selected

welding process.

Tungsten electrode melting

(Tungsten inclusions in base metal

during the ignition phase)

Incorrect tungsten electrode polarity. Connect the TIG welding torch to the (-) current

socket.

Incorrect (or no) shielding gas. Use inert shielding gas (argon).

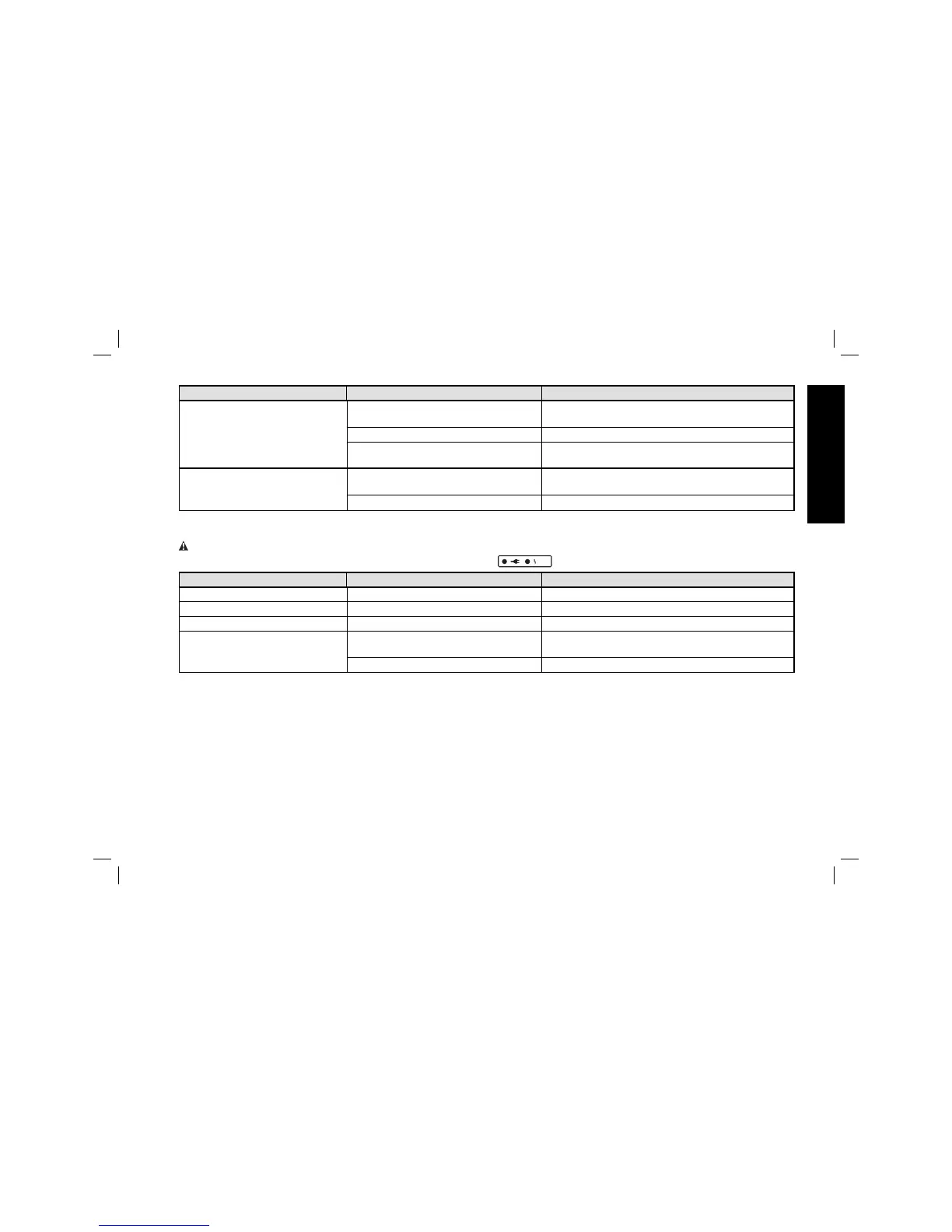

CHARGER TROUBLESHOOTING GUIDE

WARNING: An electric shock can be fatal. Do not open the device.

An error is signalled by the following indicators flashing or lighting up:

SYMPTOM/ERROR CAUSE FIX

Error fl ashing, mains lit Battery fault. Contact After-Sales Service.

Error fl ashing, mains fl ashing Mains fault (overvoltage or undervoltage) Check mains supply voltage

Error lit, mains lit Charger fault Contact After-Sales Service

Mains fuse or automatic circuit

breaker trips

Mains fuse underrated/incorrect circuit

breaker

Fuse mains correctly

Mains fuse trips in open circuit Contact After-Sales Service

Loading...

Loading...