ENGLISH

12

WARNING: NEVER use a light socket.

NEVER connect the live (L) or

neutral (N) wires to the earth

pin marked E or

.

Fitting a mains plug to 115 V units (U.K. and

Ireland only)

• The plug should be tted by a competent person. If you are in

doubt, contact an authorized D

EWALT repair agent or a qualied

electrician.

• The wires are coloured according to the following code:

live = brown

neutral = blue

• Do not connect the blue or brown wire to the earth terminal in the

plug. Connect as follows:

brown to terminal marked ‘L’

blue to terminal marked ‘N’

• The plug tted should be comply with BS EN 60309 (BS4343),

16 Amps, earthing contact position 4h.

WARNING: Always ensure that the cable clamp is correctly

and securely tted to the sheath of the cable.

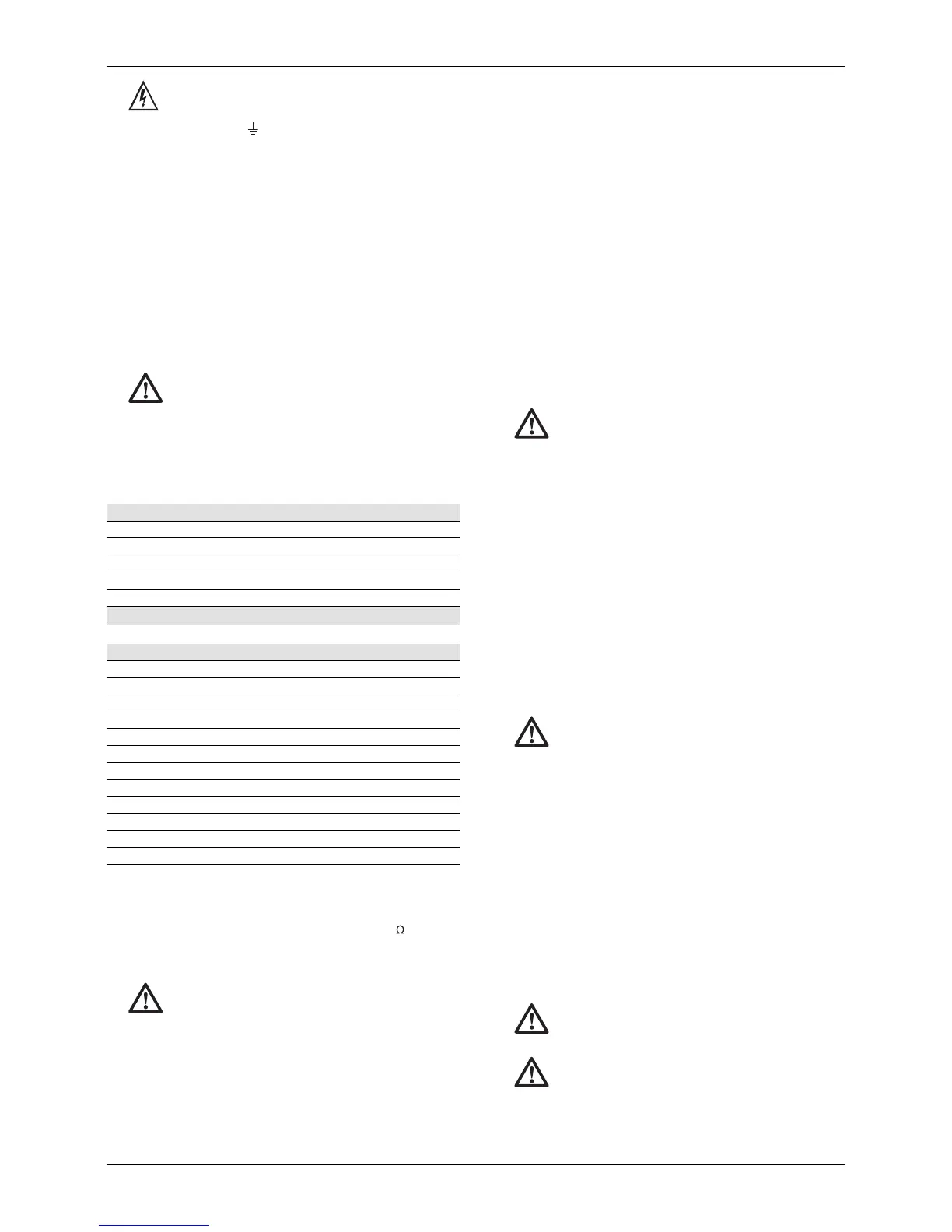

Using an extension cable

If an extension cable is required, use an approved extension cable

suitable for the power input of this tool (see technical data).

The minimum conductor size is 1.5 mm

2

. When using a cable reel,

always unwind the cable completely. Also refer to the table below.

Conductor size (mm

2

) Cable rating (Amperes)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

Cable length (m)

7.5 15 25 30 45 60

Voltage Amperes Cable rating (Amperes)

115 0 – 2.0 6 6 6 6 6 10

2.1 – 3.4 6 6 6 6 6 15

3.5 – 5.0 6 6 10 15 20 20

5.1 – 7.0 10 10 15 20 20 25

7.1 – 12.0 15 15 20 25 25 –

12.1 – 20.0 20 20 25 – – –

230 0 – 2.0 6 6 6 6 6 6

2.1 – 3.4 6 6 6 6 6 6

3.5 – 5.0 6 6 6 6 10 15

5.1 – 7.0 10 10 10 10 15 15

7.1 – 12.0 15 15 15 15 20 20

12.1 – 20.0 20 20 20 20 25 –

Voltage drops

In rush currents cause short-time voltage drops. Under unfavourable

power supply conditions, other equipment may be aected. If the

system impedance of the power supply is lower than 0.25

,

disturbances are unlikely to occur.

ASSEMBLY

WARNING: To reduce the risk of injury, turn o tool

and disconnect from power source

before attempting to

move it, changing accessories or making any adjustments

accept as written in laser adjustment instructions.

Unpacking ( g. 1, 2, 4)

1. Remove the saw from the packing material carefully using the

carrying handle (m).

2. Press down the operating handle (a) and pull out the lock down pin

(o), as shown.

3. Gently release the downward pressure and allow the arm to rise to

its full height.

Bench Mounting ( g. 5)

1. Holes (j) are provided in all four feet to facilitate bench mounting.

Two dierent sized holes are provided to accommodate dierent

sizes of bolts. Use either hole; it is not necessary to use both.

Always mount your saw rmly to prevent movement. To enhance

the portability, the tool can be mounted to a piece of 12.5 mm or

thicker plywood which can then be clamped to your work support

or moved to other job sites and reclamped.

2. When mounting your saw to a piece of plywood, make sure that

the mounting screws do not protrude from the bottom of the wood.

The plywood must sit ush on the work support. When clamping

the saw to any work surface, clamp only on the clamping bosses

where the mounting screw holes are located. Clamping at any

other point will interfere with the proper operation of the saw.

3. To prevent binding and inaccuracy, be sure the mounting surface is

not warped or otherwise uneven. If the saw rocks on the surface,

place a thin piece of material under one saw foot until the saw is

rm on the mounting surface.

Mounting the saw blade ( g. 6, 7, 8, 9)

WARNING: To reduce the risk of injury, turn o tool

and disconnect from power source before attempting to

move it, changing accessories or making any adjustments

accept as written in laser adjustment instructions.

Never depress the spindle lock button while the blade is

under power or coasting.

Do not cut ferrous metal (containing iron or steel) or

masonry or ber cement product with this mitre saw.

1. Depress the head lock up release lever (cc) to release the lower

guard (b), then raise the lower guard as far as possible.

2. Using the Torx bit in the handgrip end of the supplied wrench (i),

loosen the guard bracket screw (kk) suciently to allow the angled

corner piece (mm) to pass between the head of the screw and the

guard. This will allow the guard bracket (ll) to be raised enough to

permit access to the blade locking screw (nn).

3. With the lower guard held in the raised position by the guard

bracket scew (kk) depress the spindle lock button (x) with one

hand, then use the supplied blade wrench (i) in the other hand to

loosen the left-hand threaded blade locking screw (nn) by turning

clockwise.

WARNING: To use the spindle lock, press the button as

shown and rotate the spindle by hand until you feel the

lock engage. Continue to hold the lock button in to keep the

spindle from turning.

4. Remove the blade locking screw (nn) and the outside arbor collar

(pp).

5. Install the saw blade (oo) onto the blade adaptor (qq) seated

directly against the inside arbor collar (rr), making sure that the

teeth at the bottom edge of the blade are pointing toward the back

of the saw (away from the operator).

NOTE: For blades with a blade hole of 15.88 mm , the 25.4 mm blade

adaptor is not used.

6. Replace the outer arbor collar (pp).

7. Tighten the blade locking screw (nn) by turning counter-clockwise

while holding the spindle lock engaged with your other hand.

8. Move the guard bracket (ll) down until the angled corner piece (mm)

is below the head of the guard bracket screw (kk).

9. Tighten the guard bracket screw.

WARNING: Never press the spindle lock while the blade is

rotating. Be sure to hold the guard bracket down and rmly

tighten the guard bracket screw after installing the blade .

WARNING: The guard bracket must be returned to its

original position and the screw tightened before activating

the saw. Failure to do so may allow the guard to contact

the spinning saw blade resulting in damage to the saw and

severe personal injury.

Loading...

Loading...