Do you have a question about the Dhollandia DH-SM and is the answer not in the manual?

Explains the meaning and use of DANGER, WARNING, CAUTION, and NOTICE signs.

Provides contact details for DHOLLANDIA offices for inquiries and assistance.

Outlines installer responsibilities and DHOLLANDIA's liability disclaimers.

Emphasizes understanding and applying safety instructions from manuals for operation and installation.

Covers wearing PPE, avoiding hazards, and using proper tools during installation.

Defines key parameters (LARM, VFH, CTH, etc.) and terms used in installation.

Verifies compatibility, vehicle strength, kit completeness, and dimension checks.

Covers hydraulic connections, greasing, inspections, and initial function checks.

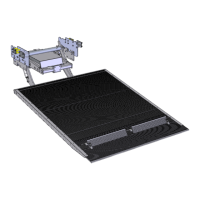

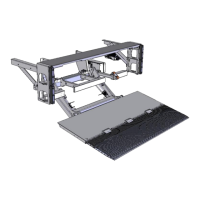

Describes mounting methods for truck chassis and trailer subframes/bogie rails.

Explains how to obtain drawings and calculate key dimensions like mounting height (mfc).

Details positioning, drilling, and securing mounting brackets based on the number of brackets used.

Covers longitudinal positioning, platform flushness, and lateral alignment of slide tubes.

Guides on preparing the lift frame and manually sliding it into the slide tubes.

Ensures slide plates are correctly mounted for DH-SMR* models.

Connects power, prepares the platform, and attaches it to the lift frame.

Assembles end stops and adjusts toothed bars for correct platform alignment and operation.

Recommends fitting end stops for platform stability and proper alignment.

Covers mounting the control box and connecting battery/ground cables.

Details connecting (+) battery and (-) ground cables to the control box and power pack.

Guides on routing the wire loom conduit and protecting it during operation.

Verifies connections, reviews manual, and ensures readiness for operation.

Tests functions, bleeds air from hydraulic circuits for smooth operation.

Executes functions, checks alignment, and verifies proper stowage in travel position.

Performs weight tests, verifies hydraulic pressure, and adjusts pressure relief valve.

Covers placement of safety, 'out of service', and identification decals.

Use the 'Out of Service' sign when maintenance or repair is required.

Explains serial number labels for inquiries, parts ordering, and capacity information.

Checks alignment and adjusts platform pitch for optimal loaded stability.

Explains safety signs and illustrates electric/hydraulic function symbols.

Illustrates symbols for electric and hydraulic functions like OPEN, LOWER, LIFT, CLOSE, SLIDE.

Details torque values for various bolt sizes (Metric/Imperial) for secure connections.

Specifies cable sizes, battery requirements, and hydraulic oil types.

Illustrates and lists grease points for SM liftgate models.

Details connecting battery cables and applying heat shrink for protection.

Addresses operator risks and recommends safe working positions and markings.

Details welding the OAM041 extension to trailer chassis cross bearers.

Describes bolting carriers to bogie rails and slide tubes to carriers.

Provides access to manuals, diagrams, and general product information.

Covers initial checks, controls, electrical, hydraulic, and frame/platform maintenance.

Includes tests for slide tubes, operational checks, weight tests, and final inspection results.

| Brand | Dhollandia |

|---|---|

| Model | DH-SM |

| Category | Lifting Systems |

| Language | English |

Loading...

Loading...