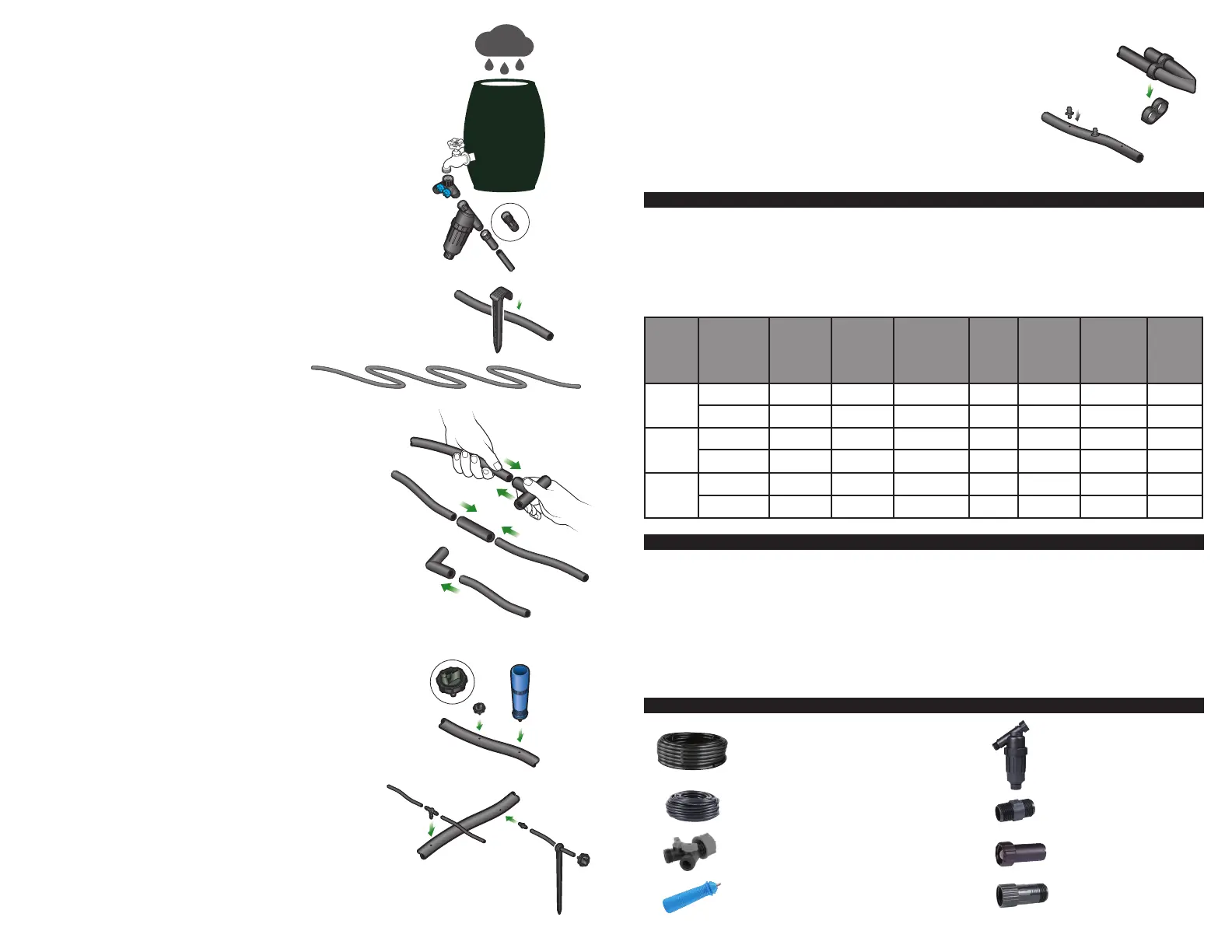

Barrel faucet connections:

Begin the installation at the rain barrel by turning the 3/4″ Y hose

end splitter (optional) onto the male threads of the rain barrel faucet.

Then, connect the 3/4″ plastic screen lter with FHT (#D57A) to one

of the splitter outlets; if the splitter is not used, connect the lter

directly to the rain barrel faucet. Next, force the end of the 1/2″ poly

tubing into the 3/4″ swivel adapter, and then connect the swivel

adapter to the lter outlet by turning it clockwise until hand tight.

Note: If you are connecting this kit to a conventional pressurized outdoor

faucet, install the included pressure regulator (#D46) onto the Y screen-

lter outlet

Drip tubing layout:

Before installing the 1/2″ poly tubing, uncoil the roll and lay it out

in direct sunlight (if possible) for 30 to 40 minutes. This will make it

more pliable and easier to work into the compression ttings during

installation.

Lay out the 1/2″ poly tubing and run it next to as many plants as

possible. Secure the tubing to the soil with the

1/2″ drip tubing stakes. Install the drip tubing in a

gentle S curve to allow for contraction of the 1/2″

tubing at low to high temperatures.

Connect the 1/2″ drip ttings

Use 1/2″ tees (part #C35) and elbows (part #C36) throughout the

layout as needed. To install the 1/2″ compression drip ttings, cut

the drip tubing with a hand pruner, being careful to keep dirt from

entering the line. Hold the tting in one hand and the drip tubing in

the other and force the drip tubing into the compression tting by

moving it from side to side.

Note: Open the faucet on the rain barrel and ush out the poly drip

tubing through the ends before installing the drip emitters.

Drip emitter installation:

The drip emitters can be installed along the poly drip tubing at

varying or specic spacings, depending on the layout of the plants. To

ensure high uniformity, take care not to exceed the recommendations

provided in the chart and the kit specications. Drip emitter ow rate

performance will depend on the rain barrel elevation.

To install the drip emitters, use one of the below options:

Option 1: Installing the drip emitters into the 1/2″ poly tubing

Insert the drip emitters directly into the 1/2″ tubing: Punch a hole

into the side of the poly tubing using the small punch (part #D44).

Snap the barbed side of the drip emitter into the hole after the lines

have been ushed.

Option 2: Installing the drip emitters into the 1/4″ micro tubing

Extend the drip emitters using 1/4” micro tubing to reach plants

that are not near the 1/2″ poly tubing. First, run a length of micro

tubing from the 1/2″ poly tubing to the plant and cut it. Then, insert

a 1/4″ barbed connector (part #H80A) into the micro tubing. Punch a

hole into the 1/2″ poly tubing and insert the 1/4″ barb into the poly

tubing. At the other end of the micro tubing, insert the barbed side

of the drip emitter after the lines have been ushed. Add a stabilizer

stake and secure to the ground.

Initial system start-up

Turn the water on again, ush the line[s], this will ush out any dirt

or debris that may be in the line. Close the end of the poly tubing

with the gure “8” hose end (part #F68B).

Test and inspect the system to identify if there are any leaks in the

drip tubing laterals. If there are any leaks from the barbed ttings or

drip emitters, remove the tting or drip emitters and insert a goof

plug to close the hole. Reinsert the barb tting or drip emitter nearby.

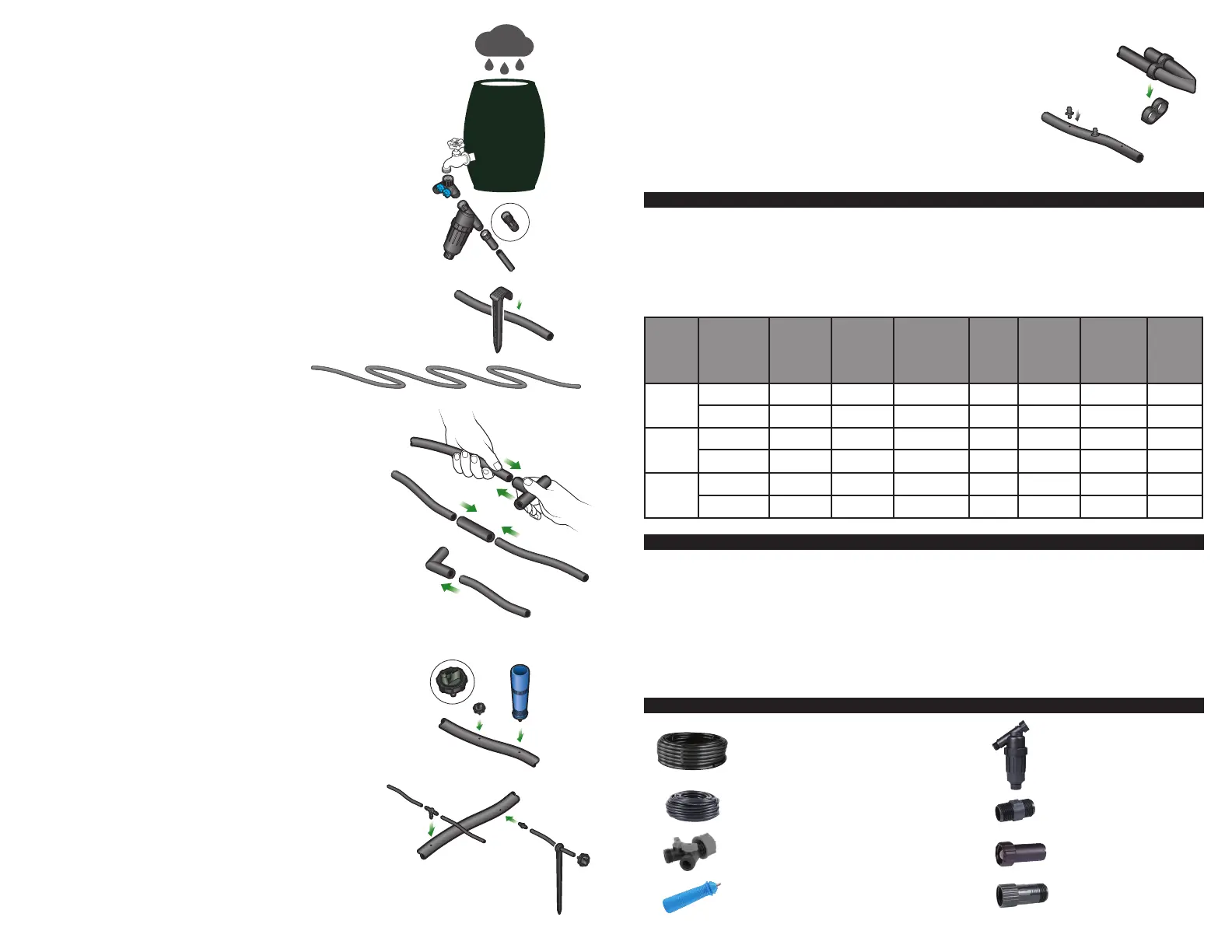

SPECIFICATION

• Operating pressure: 2 to 15 PSI

• Drip emitter ow rates: .5 GPH at 5 PSI,

.8 GPH at 10 PSI, and 1 GPH at 15 PSI (nominal)

• Drip emitter inlet size: 1/4″ barb

Rain

barrel

size

Barrel height

above the

drip sytem

Outlet

pressure

Dripper

ow rate

Length

1/2″ drip

tubing

# of

drippers

Total ow

rate per 50

drippers

Total ow

rate per 50

drippers

Avg.

barrel

time to

empty

60 gal.

227 L

5 ft 2.16 PSI 0.33 GPH Up to 60 ft 50 16.5 GPH .28 GPM 3.6 h

1.5 m .15 bar 1.25 L/H Up to 18 m 50 62.4 L/H 1.04 LPM 3.6 h

60 gal.

227 L

10 ft 4.33 PSI 0.43 GPH Up to 70 ft 50 21.5 GPH .36 GPM 2.8 h

1 m .30 bar 1.62 L/H Up to 21 m 50 81.4 L/H 1.26 LPM 2.8 h

60 gal.

227 L

20 ft 8.66 PSI 0.72 GPH Up to 80 ft 50 36 GPH .60 GPM 1.67 h

6 m .60 bar 2.7 L/H Up to 24 m 50 136 L/H 2.27 LPM 1.67 h

ABOUT THE GRAVITY FEED SYSTEM

In gravity feed systems, raising the rain barrel above the drip system will allow the system to gain

pressure. For every 1′ (30 cm) of elevation above the drip system there is a gain of .433 PSI (.030 bar). If

the rain barrel is raised 10′ (3 m) above the drip system, there is a pressure gain of 4.33 PSI (.30 bar) at

the rain barrel bottom or outlet (.433 x 10 = 4.33).

Keep in mind that low pressure such as 4.33 PSI (.30 bar) or less in a drip system will lead to:

1. Limited distance to the layout of the 1/2″ or 1/4″ drip tubing.

2. Reduction in the drip emitters’ ow rate to considerably below the specied nominal ow rate.

3. A drastic drop in uniformity once a certain length is exceeded.

• Drip emitter outlet side: nipple

• Poly tubing length & size: 100′ of

1/2″ with .600″ ID x .700″ OD

• Micro tubing length & size: 50′ x 1/4″

• Total ow rate for this kit: 32 GPH (.53 GPM)

CONTENTS

(1) 100′ of 1/2″ Black Poly Tubing

with .600″ ID x 700″ OD

part# B36

(1) 50′ of 1/4″ Black Micro Tubing

with .170″ ID x 250″ OD

part# B38P

(1) 3/4″ Y Hose End Splitter

part# D52

(1) Hole Punch

part# D44

(1) 3/4” Filter with FHT x MHT

part# D57A

(1) 3/4″ MPT x MHT Nipple

part# D49

(1) 3/4″ Faucet Adapter

part# C34

(1) 3/4″ Pressure Regulator

part# D46

D52

D57A

C34

D46

3/4” Pressure

Regulator

Loading...

Loading...