dIXEL

Operating instruction manual

1592025920

1592025920 XEV22D GB r1.0 2008.09.05.doc XEV22D 2/4

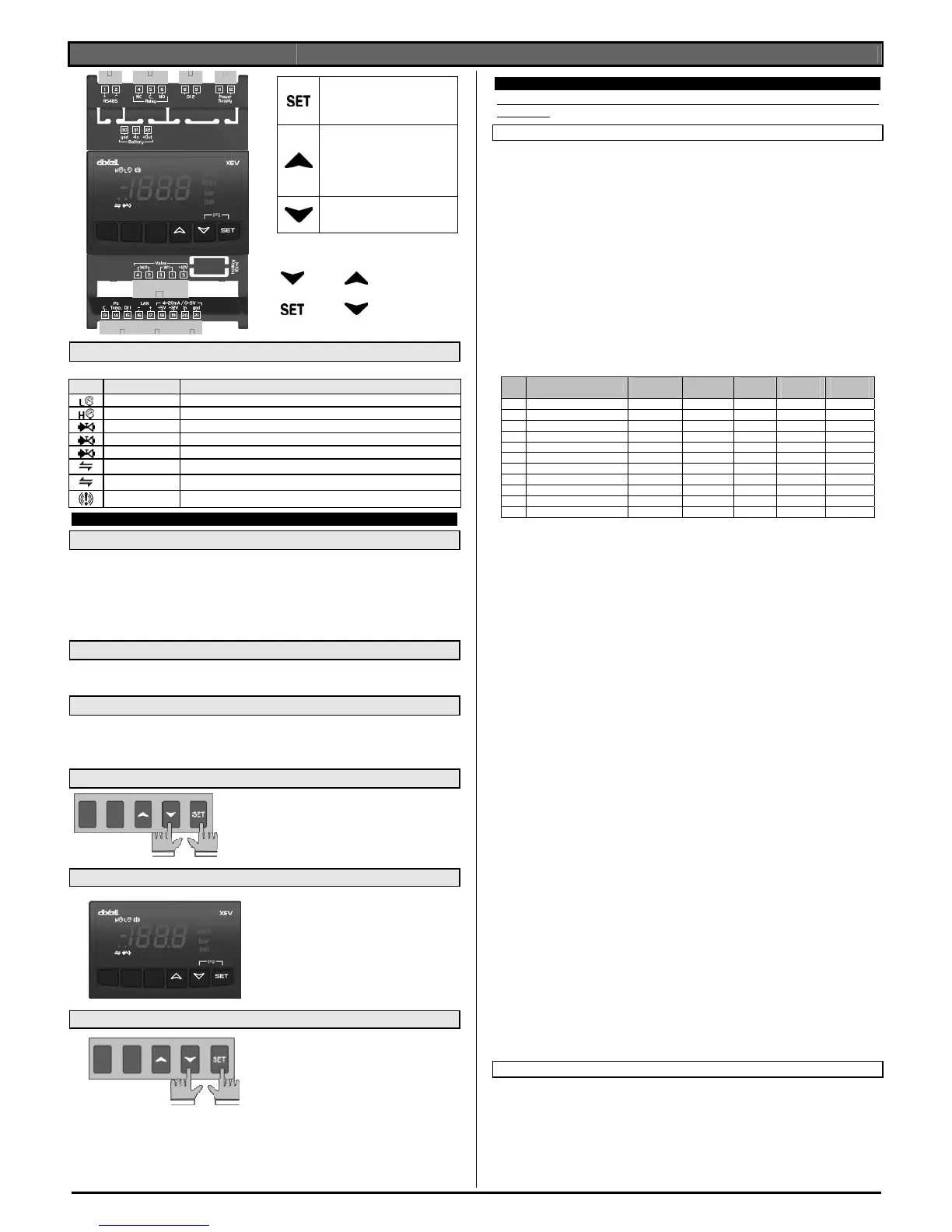

To display and to modify the set

point. In programming mode it

selects a parameter or it

confirms a value.

By pressing and releasing this

key, it’s possible to see the

values of the probes.

In programming mode it slides

the codes of the parameters or it

increases their values.

In programming mode it slides

the codes of parameters or it

decreases their values.

KEYS COMBINATIONS

+

To lock or to unlock the

keyboard

+

To enter programming

mode.

6.1 XEV22D LEDS

On display there are some luminous dots. Their meaning is described in the following table:

LED MODE Function

ON Low pressure alarm

ON Maximum Operating Pressure alarm

OFF Valve is completely closed

BLINKING Valve is moving

ON Valve is completely opened

BLINKING Serial communication present

OFF Serial communication absent

ON Superheat alarm

7. USER INTERFACE

7.1 TO SEE THE READ-ONLY VALUES

1) Press and release o key;

2) First read-only label is showed;

3) Slide labels with o or n narrows;

4) Press SET to see read-only value. To change parameter you want to see,

press SET

5) To leave the fast access menu, press and release SET+o or wait time-out of

about 3 minutes.

7.2 TO SEE THE SET POINT

1) Press the SET key until the set point will be showed;

2) To come back to see temperature, wait about 5s or press newly SET key.

7.3 TO MODIFY THE SET POINT

To change the set point value operate as follows:

1) Press the SET key until the set point will be showed;

2) Use o or n to change its value.

3) Press “SET” to store the new value.

7.4 TO GO TO “PR1” PARAMETERS

To enter in “Pr1” level menu:

1) Pressing SET+ n keys for about 3 seconds.

2) Instruments shows first parameter in Pr1

menu

7.5 TO GO TO “PR2” PARAMETERS

To enter to “Pr2” parameters list:

1. Enter to “Pr1”

2. Select “Pr2” parameter and press

SET

3. The “PAS” label will be shown, then

“0 - - “ with 0 blinking.

4. Insert “321” password through o

and n keys, then press SET to

confirm.

7.6 TO MODIFY THE PARAMETERS VALUE

To change the parameter’s value

operate as follows:

1. Enter the Programming mode by

pressing the Set and n key for

about 3s.

2. Select the required parameter.

3. Press the “SET” key to display its value

4. Use o or n to change its value.

5. Press “SET” to store the new value and move to the following parameter.

To exit: Press SET + o or wait 30s without pressing a key.

NOTE: the set value is stored even when the procedure is exited by waiting the

time-out to expire.

8. PARAMETER LIST

NOTE: All pressure parameters are relatives or absolutes depending on PrM

parameter.

REGULATION

FtY Kind of gas (R22, 134, 404, 407, 410, 507,CO2): Type of gas used by

plant. Fundamental parameter for correct functioning of all system.

PEO Probe Error opening percentage: (0÷100%) if a temporary probe error

occurs, valve opening percentage is PEo until PEd time is elapsed. If PEO

is different from 0 it assures cooling also with probe error, because even if

the device cannot calculate superheat the valve can work at PEO

percentage.

PEd Probe Error delay before stopping regulation: (0÷239 sec. –

240=On=unlimited) if probe error duration is bigger than PEd valve closes

completely. Pf message is showed. If PEd=On valve opening is PEo until

probe error finishes;

tEU Type of Stepper motor: (uP- bP) it permits to select the kind of valve.

uP= 5-6 wires unipolar valves; bP= 4 wires bipolar valves; !!!!! WARNING

!!!!! by changing this parameter the valve has to be reinitialized.

tEP Predefined valve selection: (0÷10) if tEP=0 the user has to modify all the

parameters of configuration in order to use the valve. If tEP is different

from 0 the device performs a fast configuration of the following

parameters: LSt, uSt, Sr, CPP, CHd. To select the right number please

read the following table:

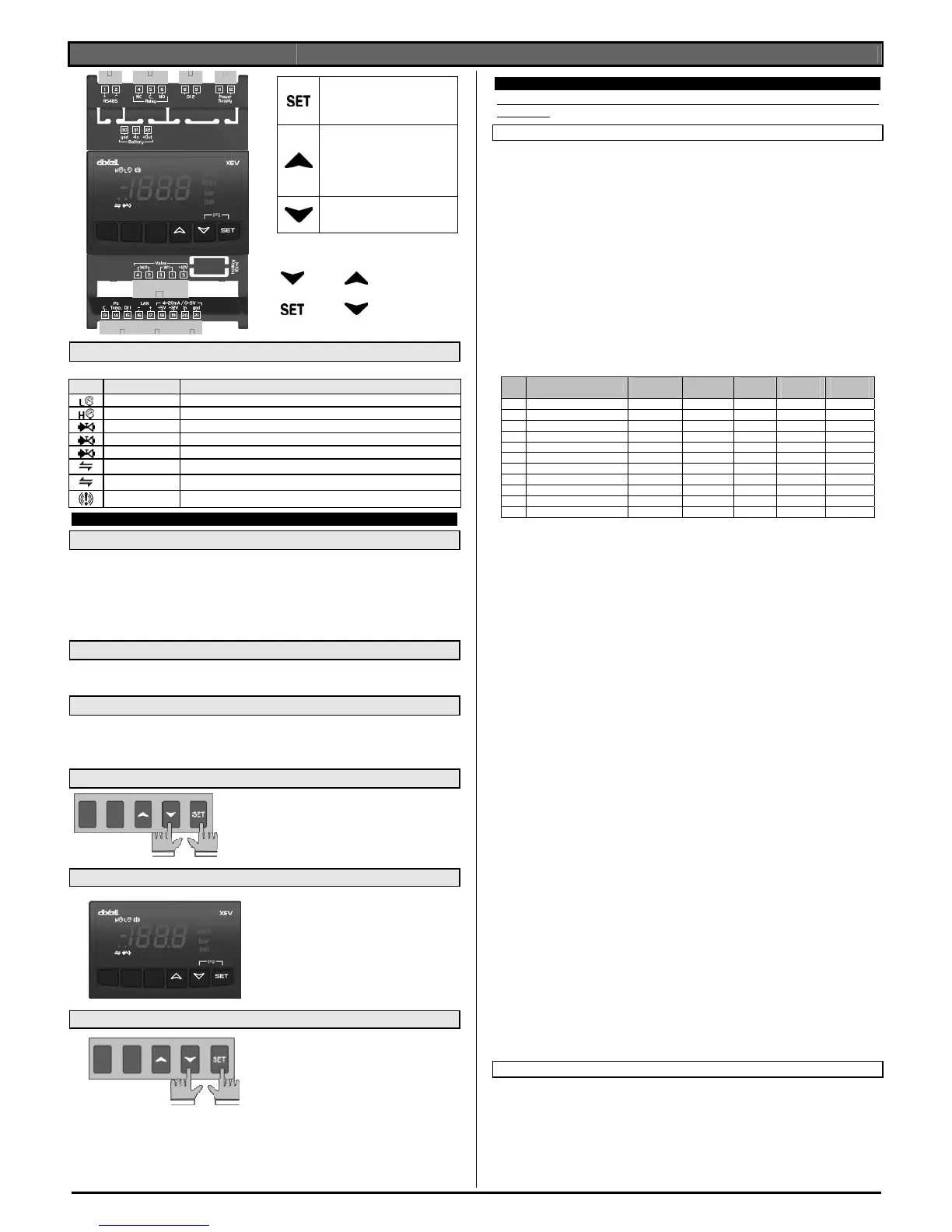

tEP Model

LSt

(steps*10)

uSt

(steps*10)

CPP

(mA*10)

CHd

(mA*10)

Sr

(step/s)

0

Manual settings

Par Par Par

Par

Par

1 Sporlan SEI 0.5-20 10 159 20 5 200

2 Sporlan SEI 30 20 319 20 5 200

3 Sporlan SEH 50-250 40 638 20 5 200

4 Alco EX5-EX6 10 75 40 10 450

5 Alco EX7 25 160 75 25 330

6 Alco EX8 330 step/s 25 260 80 50 330

7 Alco EX8 500 step/s 25 260 80 50 500

8 Danfoss ETS-25/50 20 262 14 8 120

9 Danfoss ETS-100 30 353 14 8 120

10 Danfoss ETS-250/400 35 381 14 8 120

If tEP is different from 0 previous configuration of LSt,uSt,Sr,CPP and

CHd are overwritten.

LSt Minimum number of steps: (0 ÷ USt) It permits to select the minimum

number of steps. At this number of steps the valve should be closed. So

it’s necessary the reading of manufacturer datasheet to set correctly this

parameter. It’s the minimum number of steps to stay in advised range of

functioning; !!!!! WARNING !!!!! by changing this parameter the valve

has to be reinitialized. The device perform this procedure

automatically and restart its normal functioning when the

programming mode ends;

USt Maximum number of steps: (LSt÷800*10) It permits to select the

maximum number of steps. At this number of steps the valve should be

completely opened. Read the datasheet provided by manufacturer of the

valve to set correctly this parameter. It’s the maximum number of steps to

stay in advised range of functioning; !!!!! WARNING !!!!! by changing this

parameter the valve has to be reinitialized. The device perform this

procedure automatically and restart its normal functioning when the

programming mode ends;

Sr Step rate (10÷600 step/sec) it’s the maximum speed to change step

without losing precision (=losing steps). It’s advised to stay under the

maximum speed;

CPP Current per phase (only bipolar valves): (0÷100*10mA) it’s the

maximum current per phase used to drive valve. It’s used only with

bipolar valves

CHd Holding current per phase (only bipolar valves): (0÷100*10mA) it’s the

current per phase when the valve is stopped for more than 4 minutes. It’s

used only with bipolar valves

OPE Start opening Percentage: (0÷100%) Opening valve percentage when

start function is active and during post defrost phase. This phase duration

is SFd time;

SFd Start Function duration: (0.0÷42.0 min: tens of seconds) It sets start

function duration and post-defrost duration. During this phase the

alarms are neglected

Sti Stop regulation interval: (0.0÷24.0 hours: tens of minutes) after

regulating continuously for Sti time, the valve closes for Std time in order

to prevent ice creation.

Std Stop duration: (0÷60 min.) it defines stop regulation time after Sti. During

this stop display shows StP message

MnF Maximum opening percentage at normal Functioning: (0÷100%)

during regulation it sets the maximum valve opening percentage.

FoP Forced Opening percentage: (0÷100 - nu) if FoP=nu valve works with

regulation algorithm. If Fop is different from nu the valve stays at Fop

opening percentage. This function could be useful during plant starting or

during service operations.

PI PARAMETERS (trained staff)

Loading...

Loading...