48

INSTALLATION

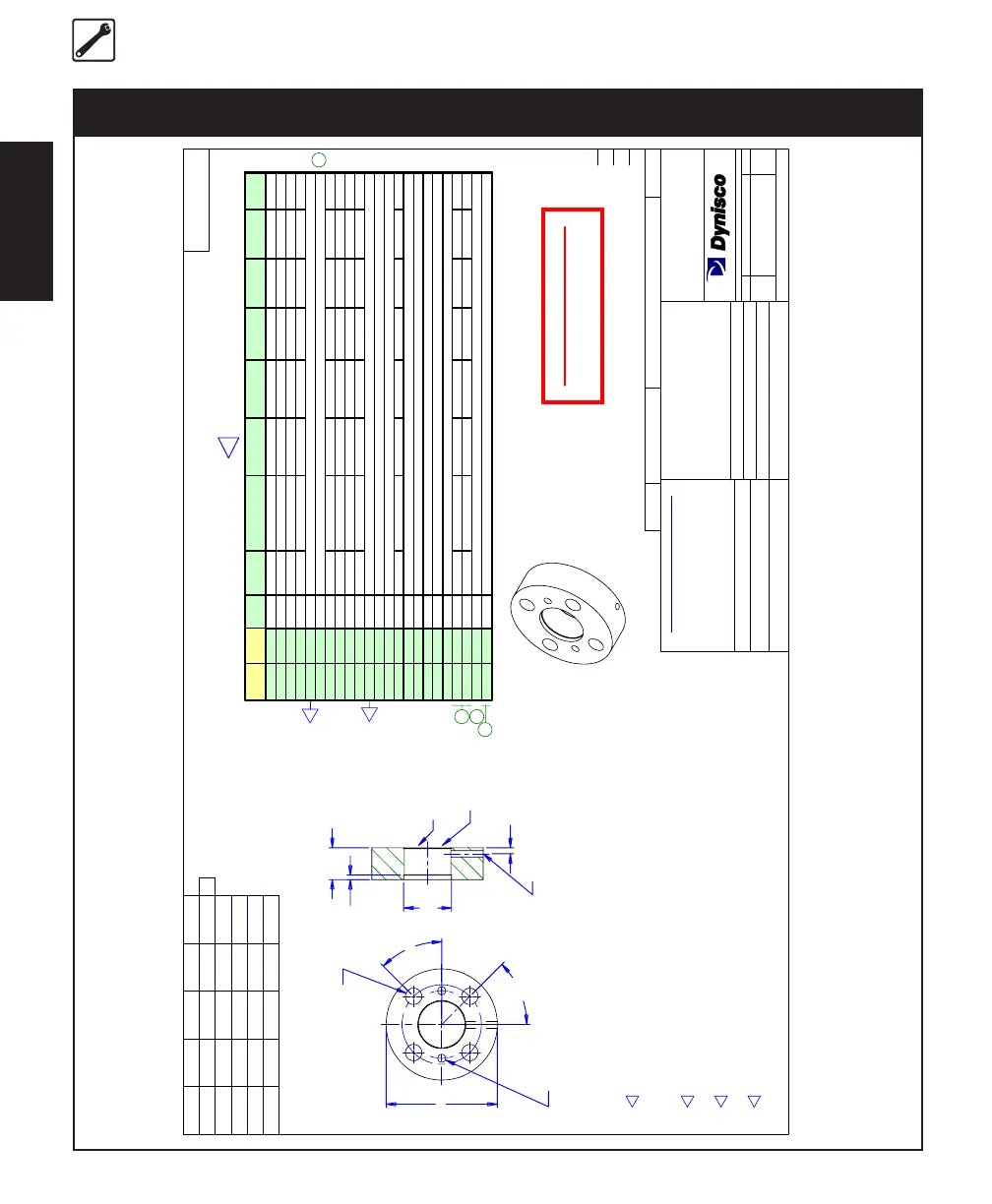

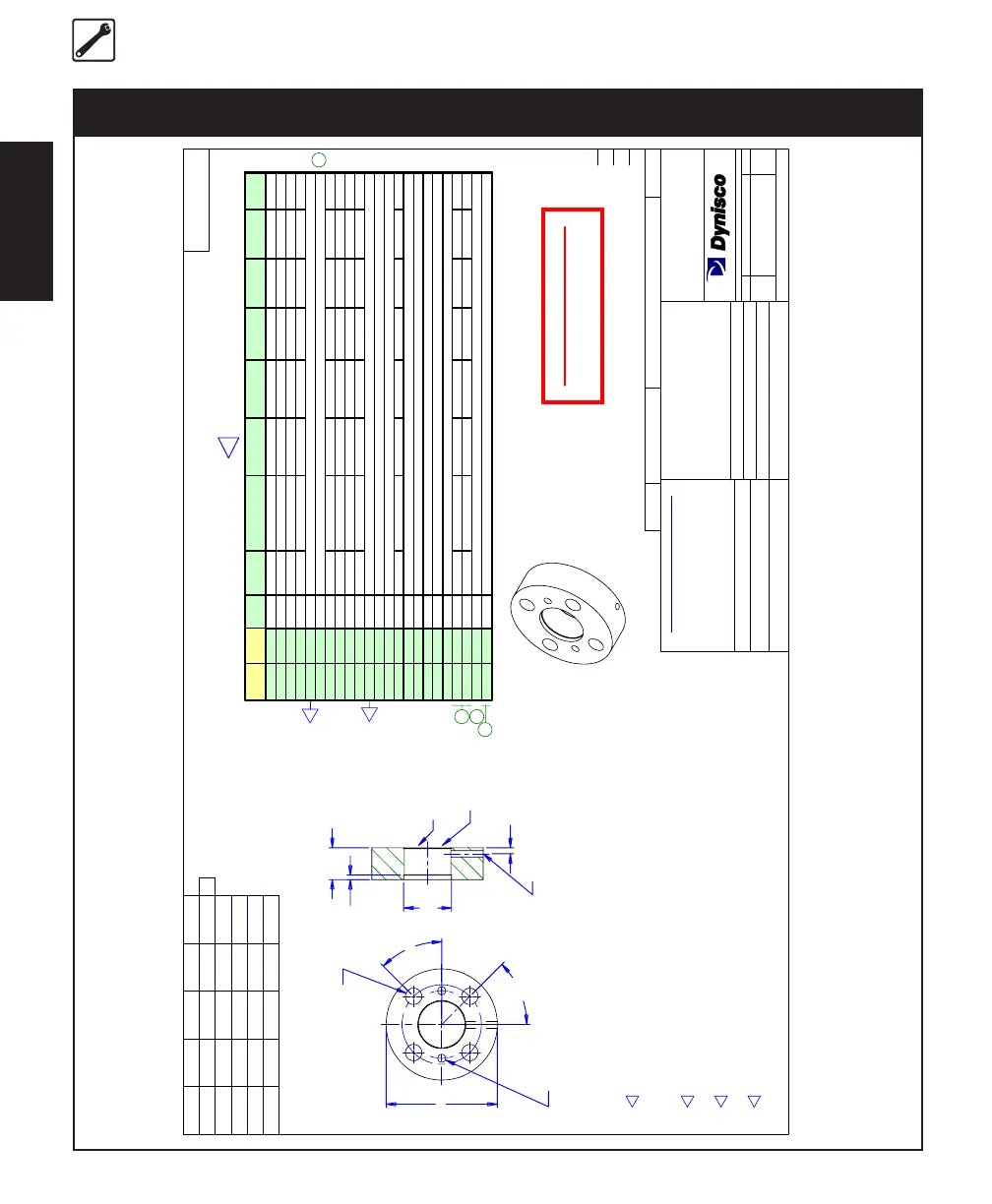

Fig. 5-11Fig. 5-11

Fig. 5-11Fig. 5-11

Fig. 5-11

2291 “S” Flange Configurations2291 “S” Flange Configurations

2291 “S” Flange Configurations2291 “S” Flange Configurations

2291 “S” Flange Configurations

1

SEE NOTE 1.

07/23/97

AD

000057

000057

NONE

B

>0.5DIA.

+.005

+.008

4. ANGLES

±

0.5

TOLERANCESUNLESS OTHERWISE SPECIFIED;

1. 2PLAC E DECIMAL

±

.01

3PLACE D ECIMAL

±

.005

5.FILLETS .005 R MAX

6.EDGES .005 R OR CHAMFERMAX

7. PARTTOBEFREE OF BURRS

8. ALL DIMENSIONSAREININCHES.

3. DRILLS<0.5DIA.

-.002

-.003

2.FRACTIONS

±

1/32

MODEL NO.

DO NOT SCALE DRAWING

MATERIAL

DRAWN

CHECKED

APPROVED

FINISH

DATE

DATE

DATE

SCALE

SHEET OF

REVDCN BY APP DATE

ITEMPARTNODESCRIPTION QTY

SIZE DWG.NO. REV

TITLE

FLANGES,TYPE'S'

10/09/97

SFP

Instruments

FORGE PARKWAY, FRA NKLIN,MA

EXCEPT AS MAY BE OTHERWISE PROVIDEDBY

CONTRACT, TH ESE DRAWINGS ANDSPECIF I CATIONS

ARETHEPROPERTY OFDYNISCO , AREISSUED IN

STRICT CONFIDENCE,ANDSHALL N OT BE

REPRODUCEDORCOPIED, OR USEDASTHE BASIS

FOR THE MANUF

ACTURE OR SALE OF APPARATUS

WITHOUT PERMISSION.

Y 29630 DRG

1

R

SFP

KEM

10/09/97

HWM

2/31/05

29712 DRGAA

HWM

3/10/05

30046DRGAB

HWM

6/17/05

30277 DRGAC

HWM

7/11/05

30580 DRGAD HWM

9/29/05

CONTROLLED PRODUCT

ALL CHANGESMUST BE APPROVEDBY

APPROVALSCO-ORDINATOR

BEFOREEXECUTION

5. UPDATE 242945 & 242946WITH ANY CHANGESORADDITIONS

TOMODEL CODINGORDESCRIPTIONS.

NOTES:

1. MATERIAL: UNLESS OTHERWISE SPECIFIED,17-4 PH SST,

COND H1075. RAW MATERIAL P/N PER ABOVETABLE.

2. ALL THR

EADS ARE UN-2B, UNLESS OTHERWISE SPECIFIED.

3. S5 IS A 150 LB - 21/2" RAISED FACE ANSIFLANGE,SEE

STANDARD ASME B16.5 FOR DIMENSIONS.

4. S11 ISA600LB - 2" RAISED FACE ANSIFLANGE,SEE

STANDARD ASM

E B16.5 FOR DIMENSIONS.

AB

AA

5

3

4

ITEM MATERIAL OUTERDIAMETERBOLT CIRCLE BOLT CIRCLE THRU HOLE JACK-OUTTHICKNESS PART

P/N P/N

∅

"A"

∅

"B"

∅

"C"

∅

"D"

THREADDIM 'T' REV

S148291625 175325 3.250 2.125 2.125 33/64 5/16-18 0.75 A

S249291682 175325 3.220 2.250 2.250 17/32 1/2-13 1.00 A

S3 50 291685 175325 3.250 2.250 2.250 17

/32 5/16-18 0.75 A

S4 51 291620 175350 3.500 3.000 2.500 17/32 5/16-18 1.00 B

S5 52 199654 REFER TOSEPERATE DRAWING FOR DIMENSIONSANDMATERIAL

S6 53 195639

S7 54 291762 175350 3.500 2.500 2.500 9/16 M12 x 1.75 0.75 A

S8 55 185603 175350 3.500 2.500 2.500 9/16 5/16-18 0.75 B

S

9 56 291606 175350 3.500 2.500 2.500 17/32 1/2-13 1.00 A

S10 57 291696 175325 3.250 2.125 2.520 33/64 5/16-18 1.00 A

S11 58 291772

S12 59 199650

S13 60 195632

S14 61 291853 175350 3.500 2.500 2.500 17/32 1/2 -13 0.75 A

S15 62 291858

S16 63 195645

S17 64 195665

S18 65 195648

S19 66 195677

S20 67 291861 17-4,H1075 7

.010 4.882 4.882 28mm M12 X 1.75 1.34 A

S21 68 291860 17-4,H1075 4.490 2.756 2.756 20mm M12 X 1.75 1.18 A

S22 291867

S23 24 291870

PERDRAWING 291870, 2" 300 LBRF, 316 SSTFLANGE,SECUREDBY SET-SCREW

291

CODE

2291

CODE

REFER TOSEPERATE DRAWING FOR DIMENSIONSANDMATERIAL

P

ERDRAWING 195639, 2" 600 LB FF 304 SST ANSIFLANGE,SECUREDBY SET-SCREW

REFER TOSEPERATE DRAWING FOR DIMENSIONSANDMATERIAL

PERDRAWING 195632, 1-1/2300LBRF 316 SSTFLANGE,w/ 1/2-20 JACKOUTHOLES,WELDED, NOSET-SCR

EW

PERDRAWING 291867, 2" 600 LBRF,304 SSTFLANGE,SECUREDBY SET-SCREW

PERDRAWING 291858, 2" 300 LBRF 304 SST ANSIFLANGE,SECUREDBY SET-SCREW

PERDRAWING 195665, 1-1/2" 2500 LBRF ANSI,WELDED, NOSET SCREW HOLE

PERDRAWING 195677, 1

" 600 LB, RF,304 SST ANSIFLANGE,WELDED

PERDRAWING 195648, 1" 2500 LBRF ANSI,SECUREDBY SET-SCREW

PERDRAWING 195645, 2" 600 LBRF 316 SST ANSIFLANGE,WELDED, NOSET-SCREW HOLE

.190

`

45

vu

5

v

2x 'JACKOUT'THREAD

EQUALLY SPACEDON A

Ø 'B' BOLT CIRCLE

4xØ'D' DRILL THRU

EQUALLY SPACEDON A

Ø 'C' BOLT CIRCLE

.140

45° ± 5°, 2PL

TO THDROOT

45

vu

5

v

Ø.201 THRU (NO.7DRILL)

ONE WALL ONLY

1/4-20 UNC-2B .53 -.56

1.506

1.502

O

Ø'A'

"T"

11/2 -16 UN-2B

AC

AD

Loading...

Loading...