Specications:

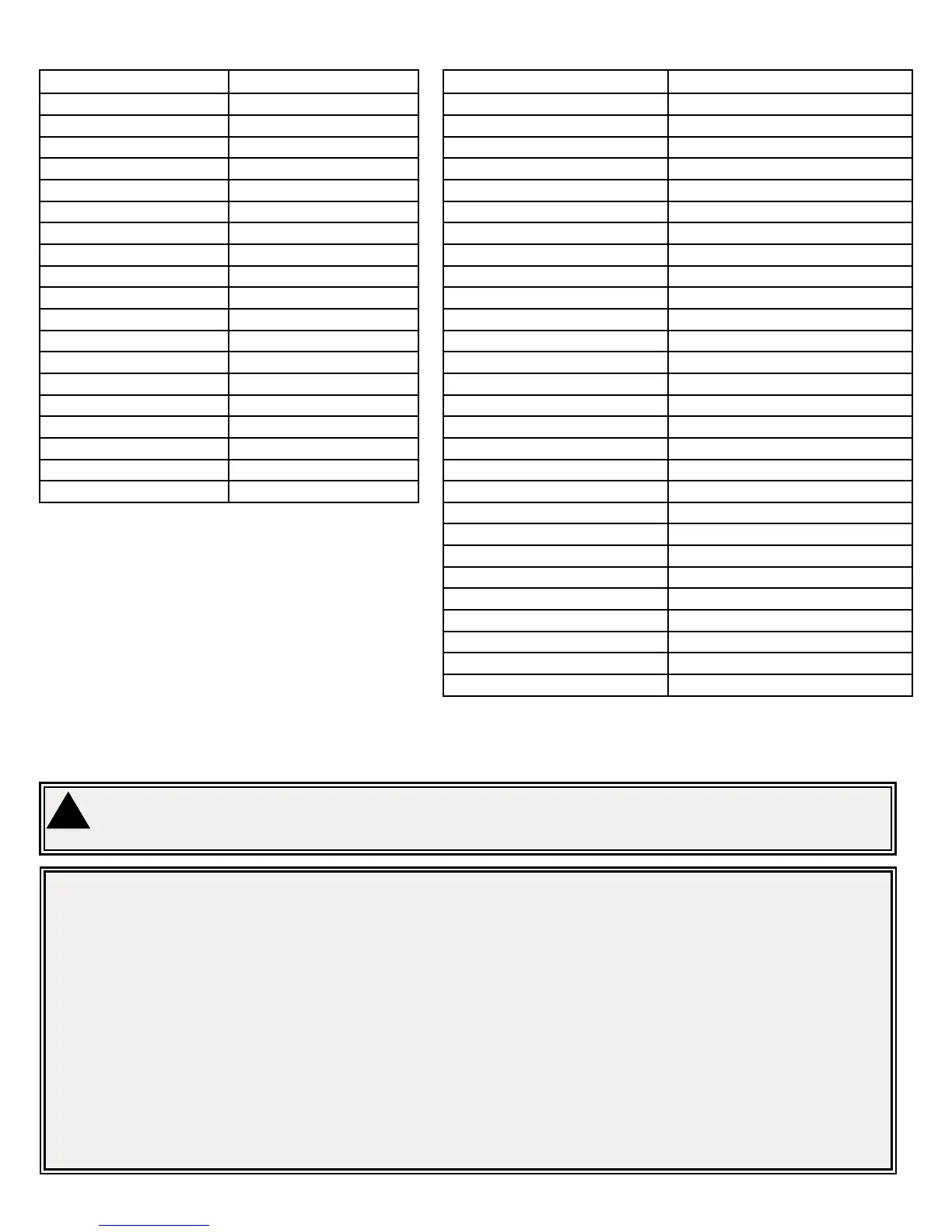

CAMERA C2013B

Image CMOS

Voltage Requirement 12V

Effective Pixels 725 x 488

Power Consumption 1W

Lens Size 1/4”

Lens Angle 120°

Audio No

Light Sensor Auto Switch B&W

Infrared LEDs 18

Pigtail Connection: CAM Male 4 Pin Threaded

Housing Aluminum Alloy

Mech. Vibration 8g

Mounting Rear/Front

Weight 0.58 lbs

Dimensions (WxHxD) 2.92”x3.01”x2.62”

Operating Temp. -4°F to 158°F

IP Rating IP69K

Approvals FCC,CE,RoHS

Current Consumption 175mA Max

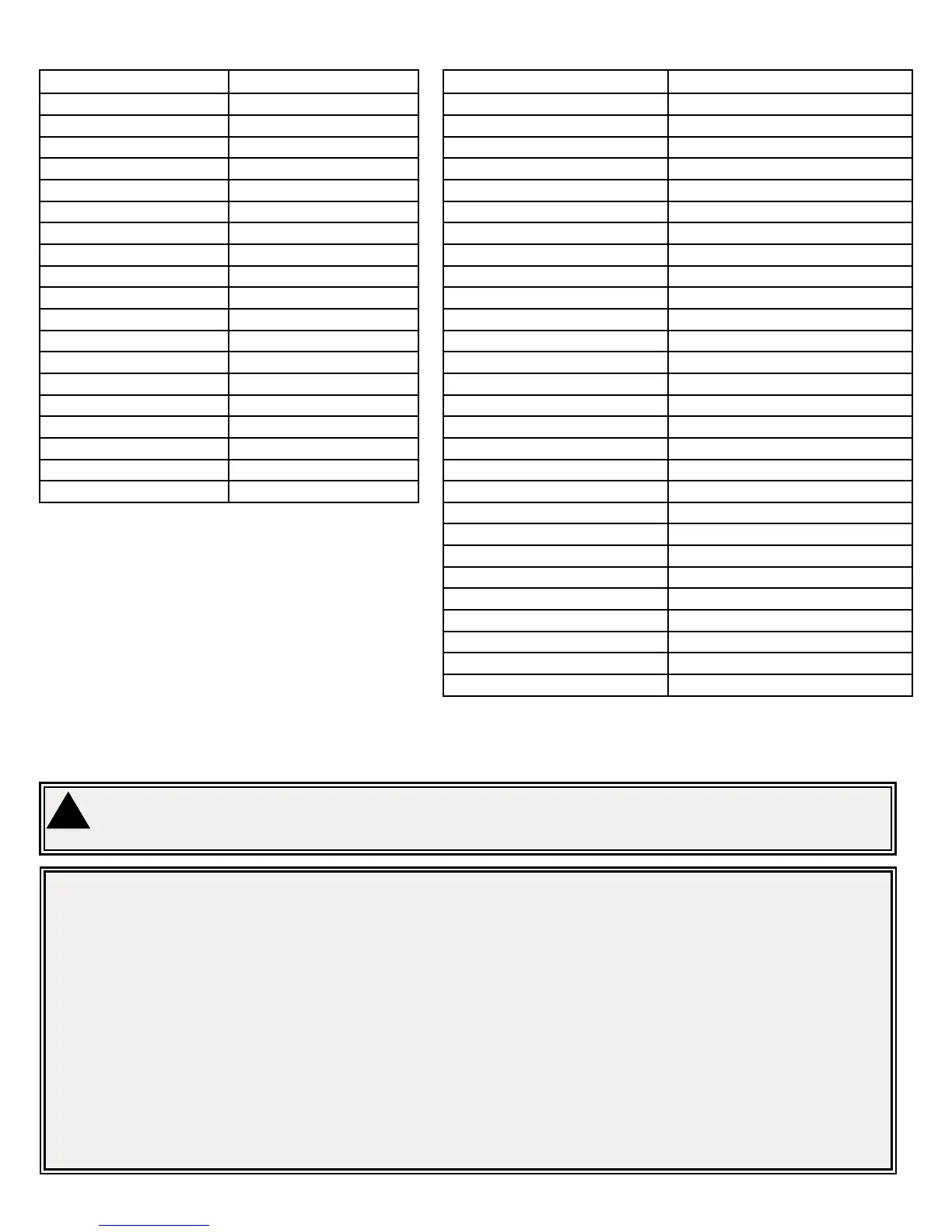

MONITOR M7000B

Screen Size 7” (4:3) and (16:9)

Controller 2 Camera

Voltage 12-24 VDC

Power Approximate: 5W

Mirror Imaging Yes (via Camera and Monitor Switch)

Resolution 800(W)XRGBX480(H)

System PAL/NTSC

Viewing Angle L/R/U/D: 60º/60º/40º/60º

Visible Area 154X86mm

Contrast 400:1

Split Screen Feature No

AV Compatible Yes

DVR Compatible No

Audio No

Brightness 400cd/m2

Light Sensor Auto Dim

Camera Selection 1-2 Via Trigger Wires

Connection: CAM Female 4 Pin Threaded

Connection (Monitor Pigtail) Male 9 Pin

Connection: CB N/A

Housing Plastic

Mounting Pedestal

Mech. Vibration Pedestal Bracket - 3G

Weight 0.88 lbs

Dimensions (WxHxD) 6.85” x 4.49” x 0.94”

Operating Temp -4°F to 158°F

Remote Control Yes

Approvals FCC,CE,RoHS

Caution! When drilling into any vehicle surface, make sure that the area is free from any electrical wires, fuel lines,

vehicle upholstery, etc. that could be damaged.

Notes:

1. Larger wires and tight connections will provide longer service life for components. For high current wires it is recommended

that terminal blocks or soldered connections be used with shrink tubing to protect the connections. Do not use insulation

displacement connectors (e.g., 3M Scotchlock type connectors)

2. Route wiring using grommets and sealant when passing through compartment walls. Minimize the number of splices to

reduce voltage drop. High ambient temperatures (e.g., under-hood) will signicantly reduce the current carrying capacity of

wires, fuses, and circuit breakers. All wiring should conform to the minimum wire size and other recommendations of the

manufacturer and be protected from moving parts and hot surfaces. Looms, grommets, cable ties, and similar installation

hardware should be used to anchor and protect all wiring.

3. Fuses or circuit breakers should be located as close to the power takeoff points as possible and properly sized to protect the

wiring and devices.

4. Particular attention should be paid to the location and method of making electrical connections and splices to protect these

points from corrosion and loss of conductivity.

5. Ground termination should be only be made to substantial chassis components, preferably directly to the vehicle battery.

6. Circuit breakers are very sensitive to high temperatures and will “false trip” when mounted in hot enviroments or operated

close to their capacity.

Loading...

Loading...