IS--1379

February 2015

Page 2 of 4

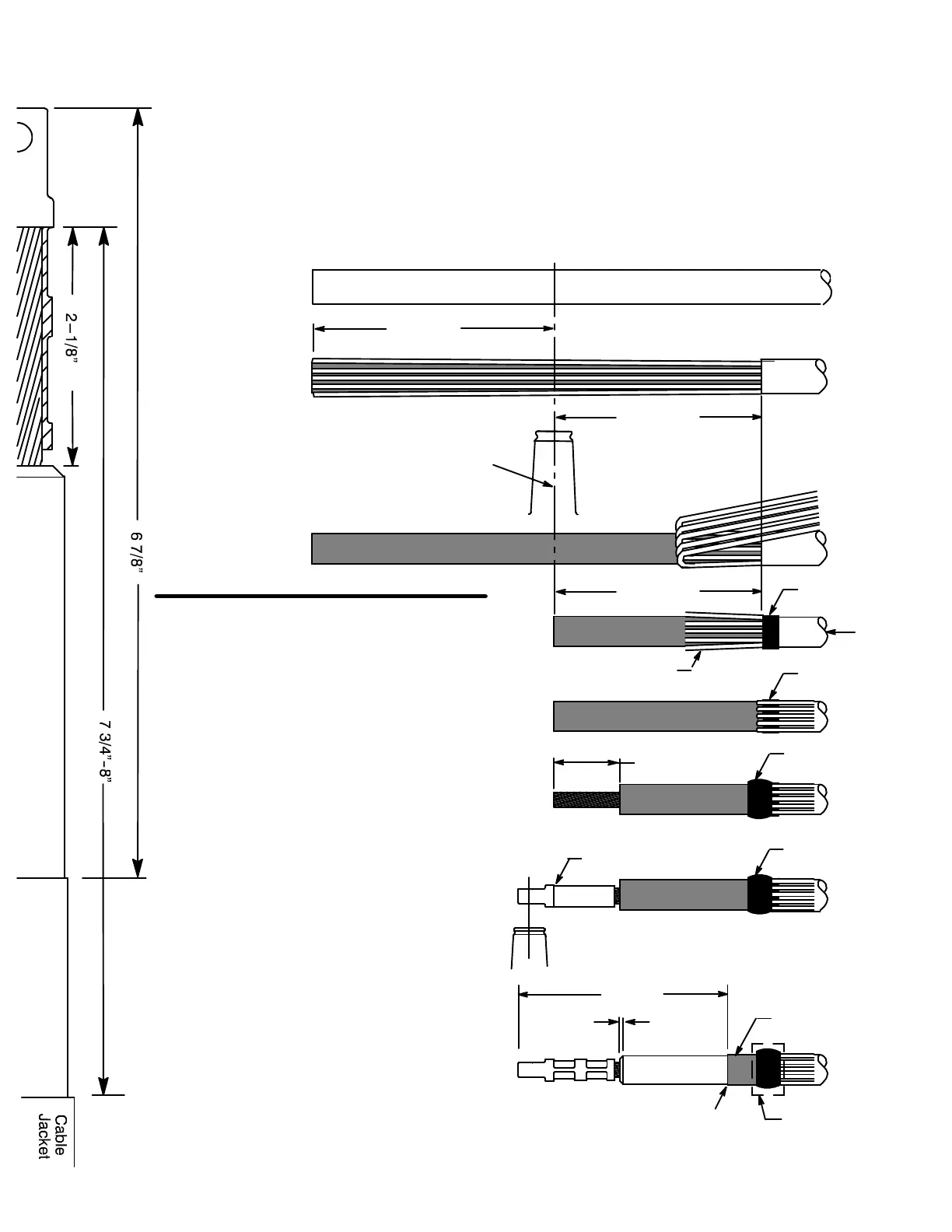

STEP 1 CABLE TRAINING

A. Train cable to ensure slack for ease of operation.

B. Use one of the two following methods to provide an extra length of concentric neutral wires or grounding

braid wire to facilitate the connection of the neutral to the tank ground and the operation of the hotstick:

1. Mark the centerline of the bushing with tape and pull extra cable to 24--26” beyond the centerline.

Remove the outer jacket 7 3/4” to 8” back from centerline.

2. Proceed to step ”D” and connect the neutral wires to the tank ground with a jumper or grounding braid.

C. Unwrap the neutral wire back past the bushing centerline.

D. Cut excess cable squarely at the centerline of the bushing.

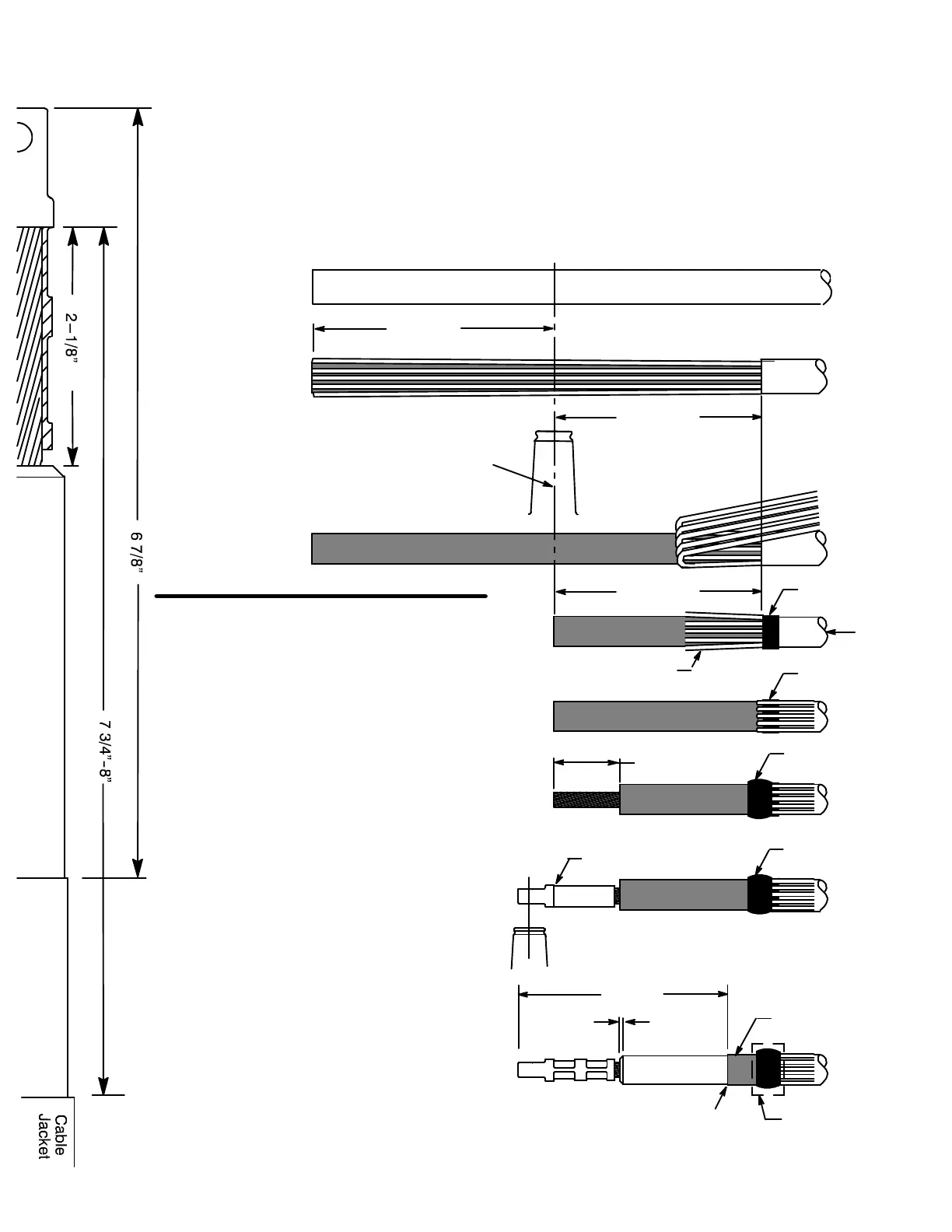

STEP 2 CABLE PREPARATION

(Use cable cut back template (to the left) for

dimensional guide.)

A. Wrap one strip of mastic, stretching slightly,

around jacket.

B. Bend all of the neutral wires straight back

over the mastic and along the cable. Press

the wires into the mastic.

C. Wrap the second strip of mastic completely

around the outer jacket, overlapping the

neutral wires imbedded into the first mastic

strip. Use the third strip of mastic, if needed,

to build--up the outer diameter in the area of

the first mastic location. Cover all mastic with

vinyl tape.

D. Remove insulation shield and insulation

from the cable end. Cut squarely taking care

not to nick conductor.

E. Wire brush bare aluminum conductors and

immediately install compression lug. Rotate

to spread inhibitor.

Position compression lug so the CONTACT

THREADED HOLE ALIGNS WITH THE

BUSHING BORE. (Refer to crimp chart

packaged with compression lug for

recommended crimp tool information.) Start

crimp at the crimp line mark. Rotate 180

0

each successive crimp. Carefully wipe

excessive inhibitor from the outside of the

lug and cable.

F. Remove insulation shield as shown. Bevel

insulation end 1/8” max.

G. Thoroughly clean insulation to remove all

traces of conductive residue.

7---3/4”--8”

2---1/8”

Start Crimp Here

First Mastic

Align lug thread

to bushing bore

6---7/8”

1/8” Max.

Bevel

Insulation

Insulation

Shield

Straight, Smooth & Squared

Do not cut or nick insulation

Second Mastic

Insulation Shield

Imbed Wires into

First Mastic Strip

Outer

Jacket

Third Mastic

Vinyl Tape

Extra Length of Wires/Braid

24” -- 26”

Bushing

Centerline

Wires/Braid not shown

Bent Back for Clarity

7---3/4”--8”

Jacketed Cable

Loading...

Loading...