29

CHECK SPARK PLUGS

Service Interval: Every 100 Hours

Remove spark plugs, check condition and reset

gaps, or replace with new plugs. See Engine

Owner’s Manual.

CHANGE HYDRAULIC SYSTEM FILTER

AND FLUID

Service Interval: Every 400 Hours

ZT-3400

This transaxle is designed with an external filter

for ease of maintenance. To ensure constant

fluid quality levels and longer life, an initial oil

and filter change at 75-100 hours, then every

400 hours thereafter is recommended.

The following procedure can be performed with

the transaxles installed in the vehicle, and the

vehicle on level ground. Apply the bypass

valve for each transaxle and lock the vehicle

parking brake.

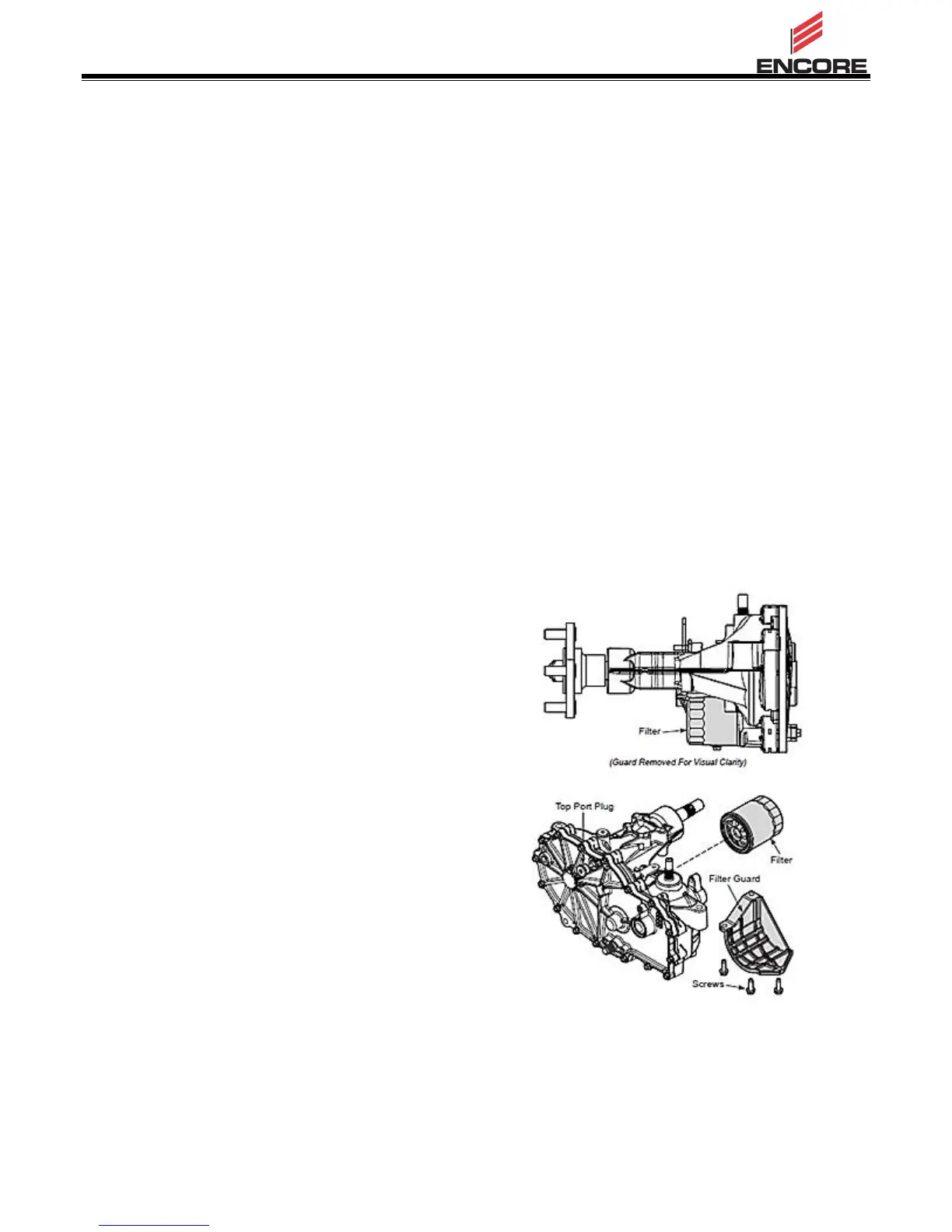

1. Remove the three 1/4” filter guard screws

and filter guard. Clean any loose debris

from around the perimeter of the filter. See

figure below.

2. Place an oil drain pan (12” or more diameter

and 8 qt. capacity is optimal) beneath the oil

filter. Remove the oil filter from the

transaxle.

3. After the oil has drained, wipe the filter base

surface off and apply a film of new oil to the

gasket of the new replacement filter (Hydro-

Gear part number 52114).

4. Install the new filter by hand, turn 3/4 to one

full turn after the filter gasket contacts the

filter base surface.

5. Re-install the filter guard with three 1/4”

screws. Torque screws to 65 in/lbs (7.3 Nm)

each.

6. Repeat steps 1-5 on the opposite side

transaxle drive.

7. Drain old oil filters of all free flowing oil prior

to disposal. Place used oil in appropriate

containers and deliver to an approved

recycling collection facility.

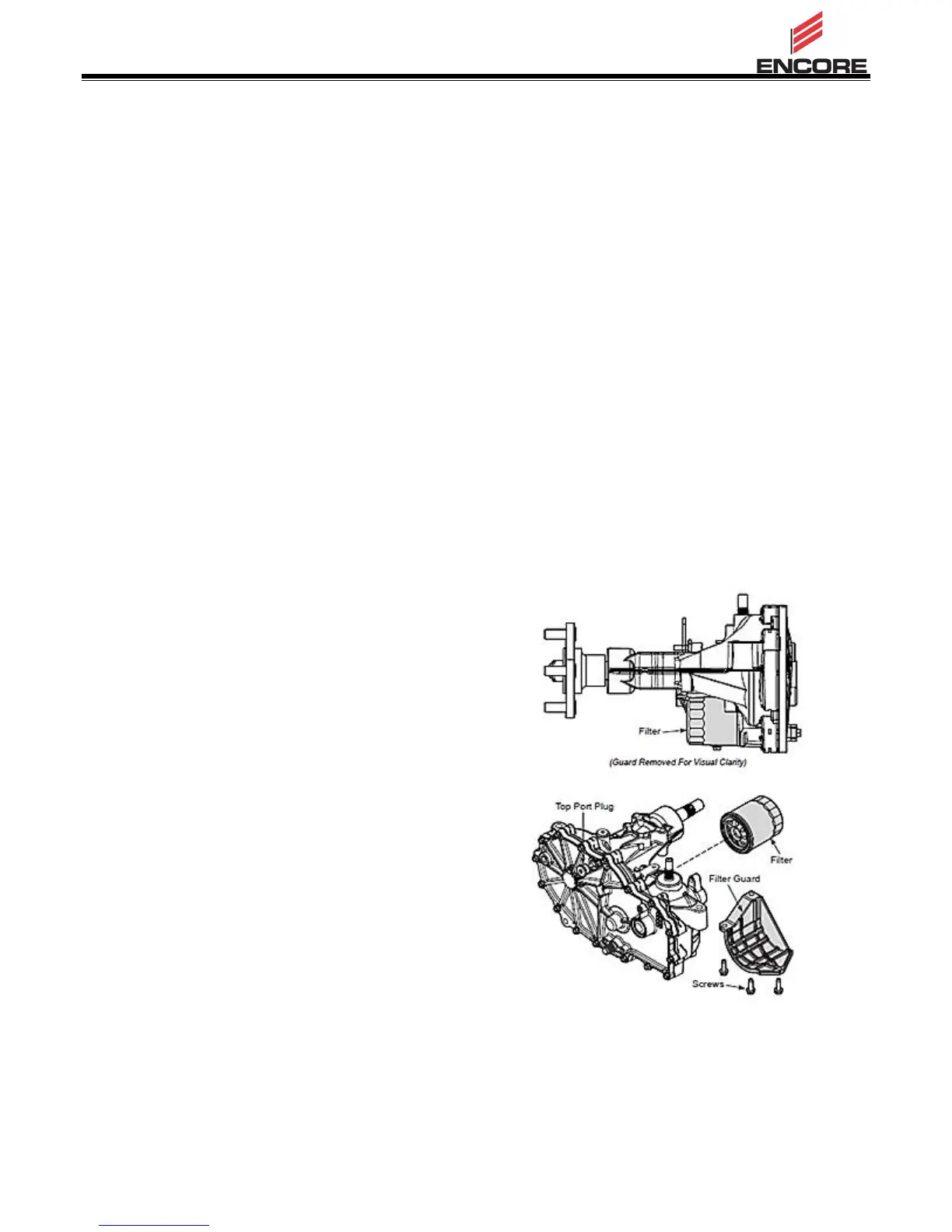

8. Remove the top port plug from the left side

and right side transaxles prior to filling with

oil. This will allow the transaxles to vent

during oil fill.

9. Remove the cap from the transaxle’s

expansion tank located on the vehicle frame.

10. Fill with 20W50 motor oil until oil just

appears at the bottom of each transaxle’s

top port (approximately 2 qts. Per transaxle,

4 qts. Total). Install the top port plug into

each transaxle as the oil level reaches this

port. See figure below.

11. Install and torque the top port plugs to 180

in/lbs (20.3 Nm).

12. Continue to fill the transaxles through the

expansion tank until the “Full Cold” line is

reached on the Hydro-Gear expansion tank.

13. Re-install the expansion tank cap by hand.

Be careful to not over-tighten.

14. Proceed to the purge procedure.

Loading...

Loading...