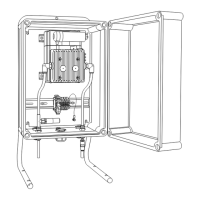

Maintenance ISEmax compressed air cleaning unit (230 V AC)

14 Endress+Hauser

7.2 Switching on the cleaning unit

L

CAUTION

Hot surfaces in open housing!

Risk of burns if touched!

‣

Always wear heat-protection gloves to touch components in the open housing after

prolonged operation of the device.

NOTICE

Damage to property from non-designated use!

‣

The device is designed for interval operation, i.e. maximum 3 minutes cleaning, break of at

least six times the cleaning time.

‣

Do not start up the device against a pressure load and do not subject it to pressure when at

a standstill.

‣

Use the device only to convey air. Never use the cleaning unit to convey liquids and

aggressive and/or toxic media.

‣

Protect the device against spray or splash water and excessive dust.

For more information on "Creating cleaning programs with the transmitter firmware", see

BA00444C.

8 Maintenance

L

WARNING

Device is live!

Risk of serious or fatal injury from electric shock!

‣

Disconnect the device from the mains voltage.

‣

Secure the device to prevent it from being switched on again unintentionally.

Take all the necessary precautions in time to ensure the operational safety and reliability of

the entire measuring system.

NOTICE

Effects on process and process control!

‣

When carrying out any work on the system, bear in mind any potential impact this could

have on the process control system and the process itself.

‣

For your own safety, only use genuine accessories. With genuine parts, the function,

accuracy and reliability are also ensured after maintenance work.

8.1 Maintenance schedule

1. Check the compressed air supply to the sensor at regular intervals.

2. As the only wear part, the seal lip of the ribbed cover must be replaced after a long time

in service.

You know that the seal lip needs to be replaced if the conveying capacity drops

noticeably.

Loading...

Loading...