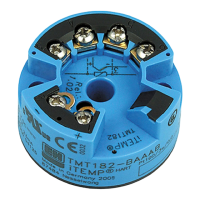

TMT162

Endress+Hauser 7

Protocol-specific data

HART

®

Version 5

Device address in multi-drop mode Software setting

Write lock Write lock activated by hardware or software setting

Device description files (DD) Information and files available free of charge online at:

www.endress.com

www.hartcom.org

Load (communication resistance) Min. 250 Ω

FOUNDATION Fieldbus™

Supported functions Instantiation of function blocks. The following methods are supported:

• Quick Setup

• User sensor trim

• Factory trim settings

• Callendar Van Dusen

• Sensor Polynom

Refer to the relevant Operating Instructions for detailed descriptions.

Basic data

Manufacturer ID 452B48 (Endress+Hauser)

Device type 10CC (Hex)

Device or bus address 245 (default)

Device revision 01 (hex)

ITK version 4.61

ITK certification diver no. IT035400

Link Master functionality supported (LAS) Yes

Link Master/Basic Device selectable Yes; factory setting: Basic Device

Virtual Communication Relationship (VCRs)

Number of VCRs 44

Number of link objects in VFD 50

Permanent entries 44

Client VCRs 0

Server VCRs 5

Source VCRs 8

Sink VCRs 0

Subscriber VCRs 12

Publisher VCRs 19

Link settings

Slot time 8

Min. Inter PDU delay 12

Max. response delay 80

Blocks

Block description Execution time (macro cycle ≤ 500 ms) Block class

Loading...

Loading...