DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

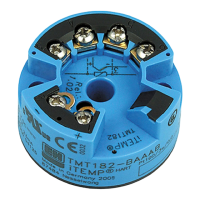

iTEMP TMT71/72 Electrical connection

5 Electrical connection

5.1 Connection conditions

L

CAUTION

Switch off the power supply before installing or connecting the device. Failure to

observe this may result in the destruction of parts of the electronics.

When connecting Ex-certified devices, please take special note of the instructions and

connection schematics in the Ex-specific supplement to these Operating Instructions.

Your supplier is available for assistance if required.

Do not occupy the display connection. An incorrect connection can destroy the

Do not overtighten the screw terminals, as this could damage the transmitter. Use a

Maximum torque for securing screws = 1 Nm (¾ foot-pound), screwdriver: Pozidriv Z2

Maximum torque for screw terminals = 0.35 Nm (¼ foot-pound), screwdriver: Pozidriv

Proceed as follows to wire a mounted head transmitter:

1. Open the cable gland and the housing cover on the terminal head or the field

2. Feed the cables through the opening in the cable gland.

3. Connect the cables as shown in → 15.

4. Tighten the cable gland again and close the housing cover.

In order to avoid connection errors always follow the instructions in the post-connection

check section before commissioning!

Sensor input

RTD, ! : 4-, 3- and 2-wire

Bus connection

and supply voltage

1

1

2

2

Display connection/

service interface

A0036348-EN

6 Terminal assignment of head transmitter

To operate the device via the HART

®

protocol (terminals 1 and 2), a minimum load of 250

Ω is required in the signal circuit.

Endress+Hauser V. 1, Rev. 2, 4-10-2018 15

Loading...

Loading...