Liquiphant FTL31 Diagnostics and troubleshooting

Endress+Hauser 33

8 Diagnostics and troubleshooting

8.1 Diagnostic information via LED display

LED display on housing cover

Malfunction Possible cause Corrective action

Green LED

Not lit

No power supply

Check connector, cable and power supply

Red LED

Flashing

Overload or short-circuit in

load circuit

• Rectify short-circuit

• Reduce maximum load current to below 250 mA

Red LED

Lit

Internal sensor failure or sensor

corroded

Replace device

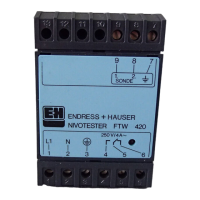

Connection: 2-wire AC/DC to 20 to 253 V DC

Malfunction Possible cause Corrective action

Unexpected behavior

of yellow LED

Incorrect connector assignment or

incorrect cable wiring

Pay attention to the polarity of the power supply!

Correct connection:

Valve plug: L+ to PIN1, L- to PIN 3

Cable: L+ BK (black), L- BN (brown)

Result (for MIN operating mode)

• Tuning fork covered: yellow LED lit.

• Tuning fork not covered: yellow LED not lit.

Result (for MAX operating mode)

• Tuning fork covered: yellow LED not lit.

• Tuning fork not covered: yellow LED lit.

9 Maintenance

No special maintenance work is required.

9.1 Cleaning

The sensor must be cleaned if necessary. It can also be cleaned while installed (e.g. CIP

Cleaning in Place / SIP Sterilization in Place). Care must be taken to ensure that no damage

occurs to the sensor in the process.

Loading...

Loading...