15

Recommended service intervals are:

a) 3 months – Heavy Duty use

b) 6 months – Normal use

c) 12 months – Infrequent use

Non destructive testing must be carried

out if the tool has been used under severe

conditions.

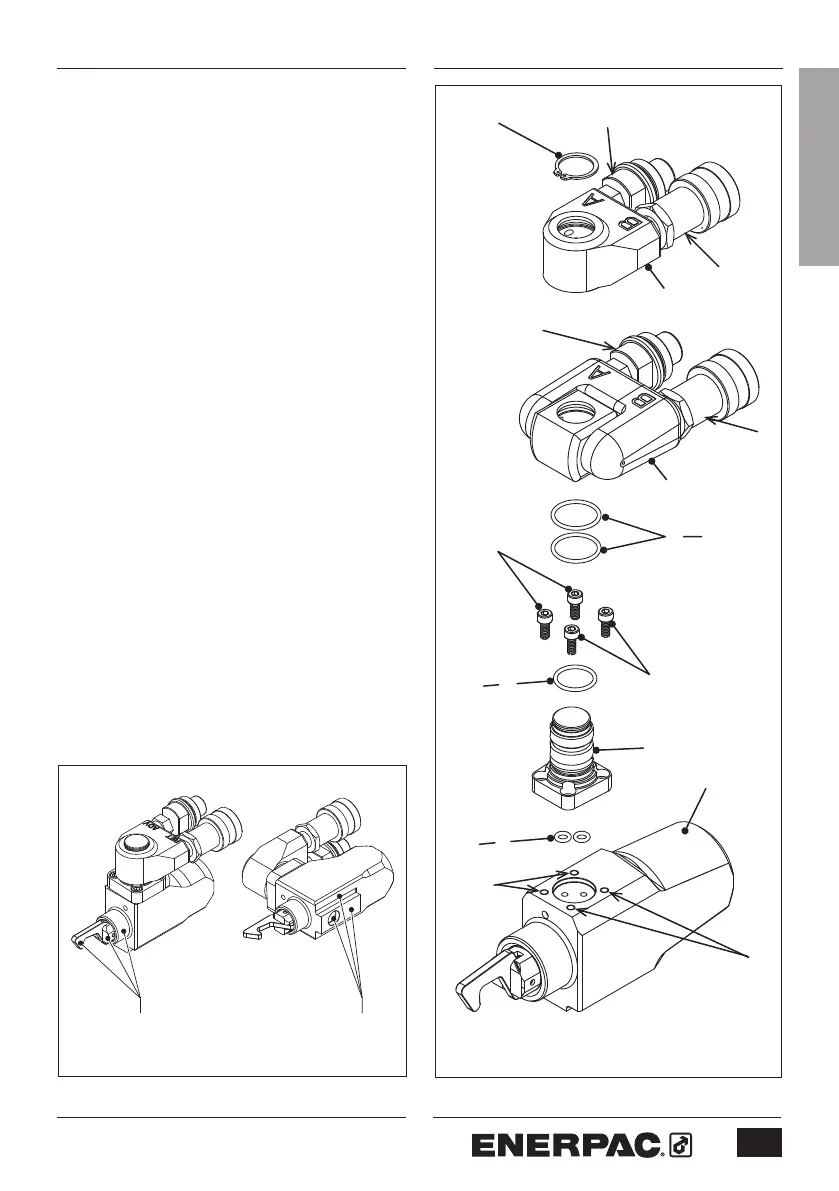

5.2 Preventative Maintenance -

Hydraulic Swivel and Drive Unit

(Fig. 13 and 14)

• Check tightness of swivel post

capscrews and gland (see 5.3).

• Pressurize the drive unit to maximum

pressure (advance and retract), and

check for any signs of leakage.

• Any damaged components or seals must

be replaced.

• Dry all components and apply a thin

coat of molybdenum disulphide grease

as indicated (✜).

5.3 Full Maintenance - Hydraulic Swivel

and Drive Unit (Fig. 14, 15 and 17)

Disassembly:

• Remove the circlip (A).

• Using a pair of flat blade screwdrivers,

gently pry the swivel assembly (B) from

the swivel post (F).

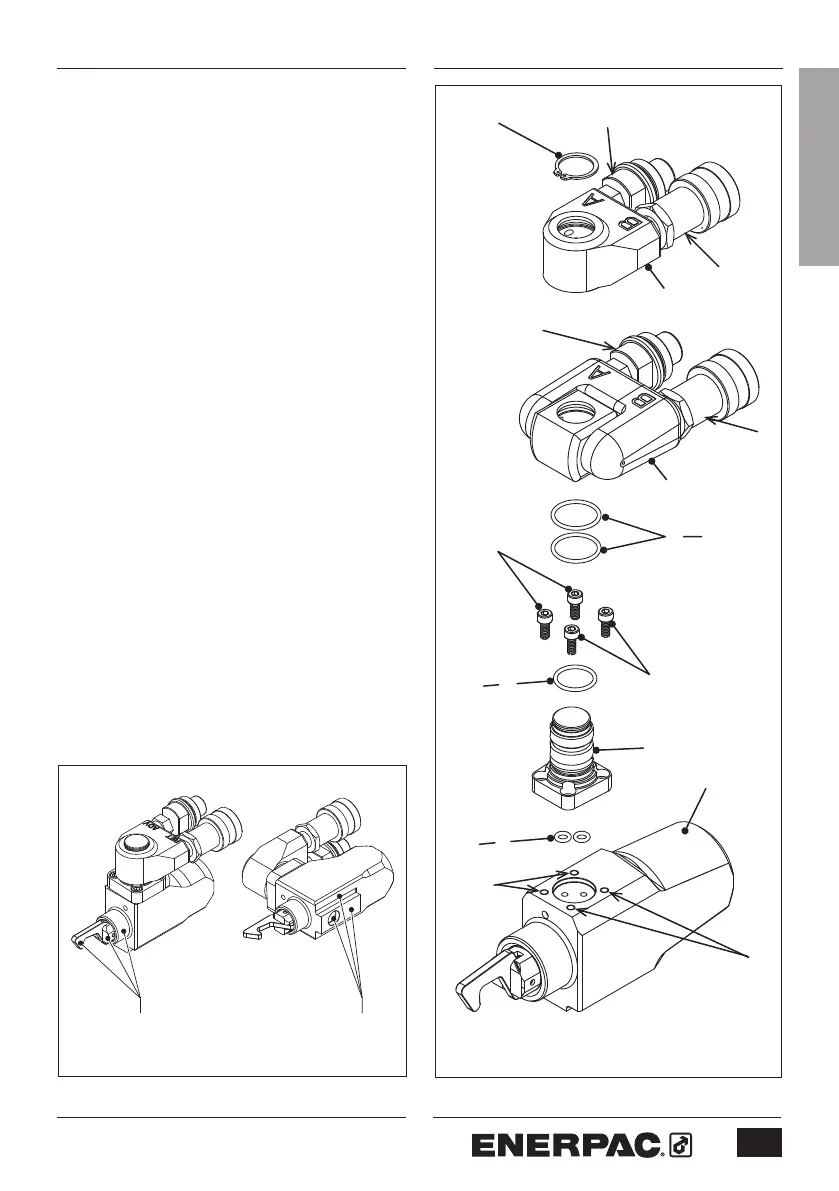

Fig. 14

✜

✜

Fig. 13

E

F

G

B

C

B

A

H

✽

✽

◆

◆

◆

◆

✤

✤

✤

D

D

Standard

Swivel

TSP300 Pro

Series Swivel

✜ molybdenum disulphide grease

✽ Loctite 243

◆ Loctite 577

Thread Sealant:

✤ Silicone Grease

ENGLISH

Loading...

Loading...