18

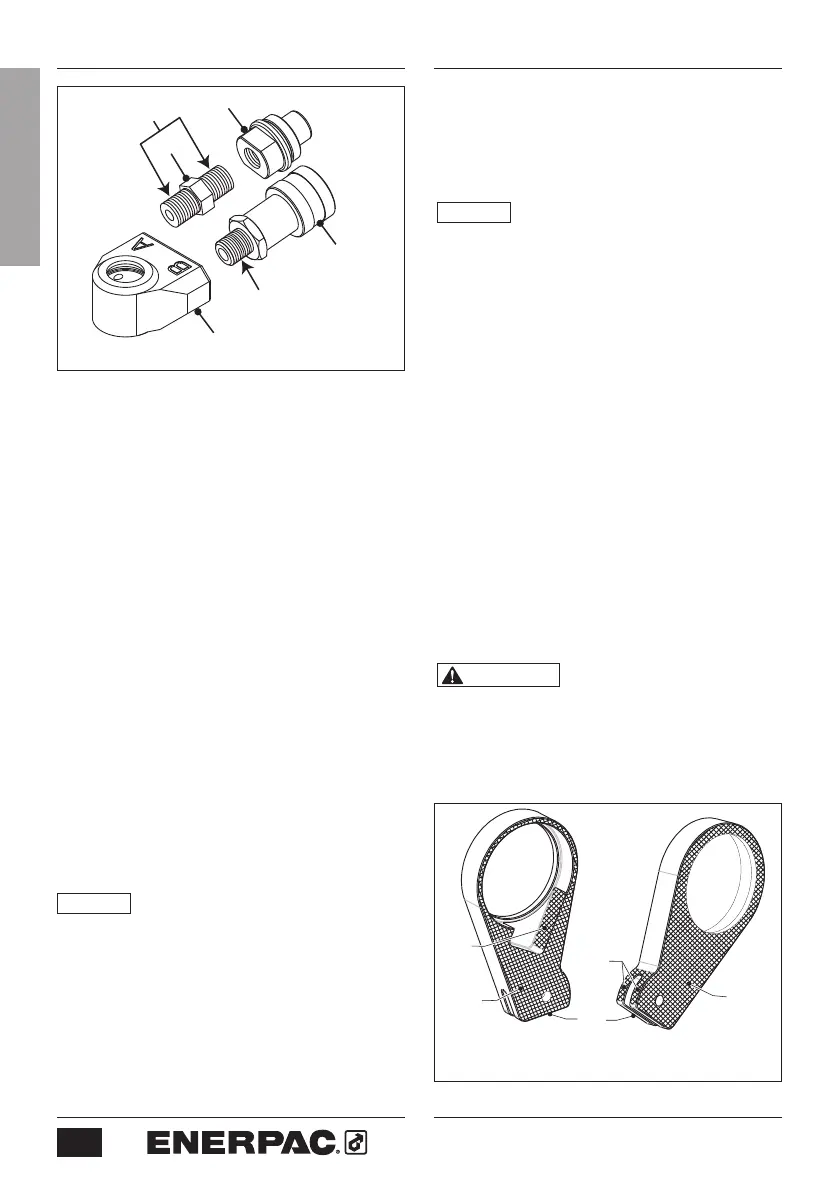

• Tighten the couplings (B1 and B3) and

adapter (B2) by hand, until they are each

finger tight. Then, wrench tighten these

parts an additional 2 to 3 turns beyond

finger tight.

NOTICE

To allow the sealant sufficient

time to cure, wait a minimum period of 3

hours at 68 to 104°F [20 to 40°C], or 6

hours at 40 to 68°F [5 to 20°C] before

pressurizing the drive unit.

•

Install a O-ring (E) into the groove on the

swivel post (F).

•

Install O-rings (C) into the grooves inside

the swivel assembly (B).

• Coat O-rings (E and C) with a small

amount of silicone grease. Then,

carefully slide the swivel assembly (B)

onto the swivel post (F).

• Reinstall the circlip retainer ring (A).

• Connect hydraulic hoses and cycle the

drive unit at 1,000 psi [69 bar] to check

for oil leaks. If there are no leaks, cycle

the drive unit at 10,000 psi [690 bar]

and check again for leaks.

WARNING

Pressurized hydraulic oil

can penetrate the skin and could cause

serious personal injury. Always repair any

oil leaks before using the wrench.

• Apply a small amount of Loctite 243

thread sealant to the threaded holes in

the drive unit. See (✽) in Figure 14 for

locations.

• Install two O-rings (G) into the ports on

the base of the swivel post (F).

• Place the swivel post (F) on the drive unit

(H), making sure that hydraulic ports are

aligned. Be careful that O-rings (G) do

not drop out or become pinched or cut.

•

Install the degreased socket head

capscrews (D) and tighten them as follows:

a) W2000X and W4000X:

(M4 capscrews) – 3.7 Ft.lbs [5.1 Nm]

b) W8000X and W15000X:

(M5 capscrews) – 7.5 Ft.lbs [10.2 Nm]

• If the drive unit is equipped with the

optional TSP300 Pro Series swivel, refer

to Enerpac instruction sheet L4119 for

additional reassembly instructions.

NOTICE

Install the couplings (B1 and B3)

and adapter (B2) before installing the

swivel (B) on the swivel post (F). Use a vise

with soft jaws to hold the swivel as

couplings and adapter are installed.

• Apply Loctite 577 sealant to threads on

female coupling (B3) and adapter (B2).

See (◆) in Figure 17 for locations.

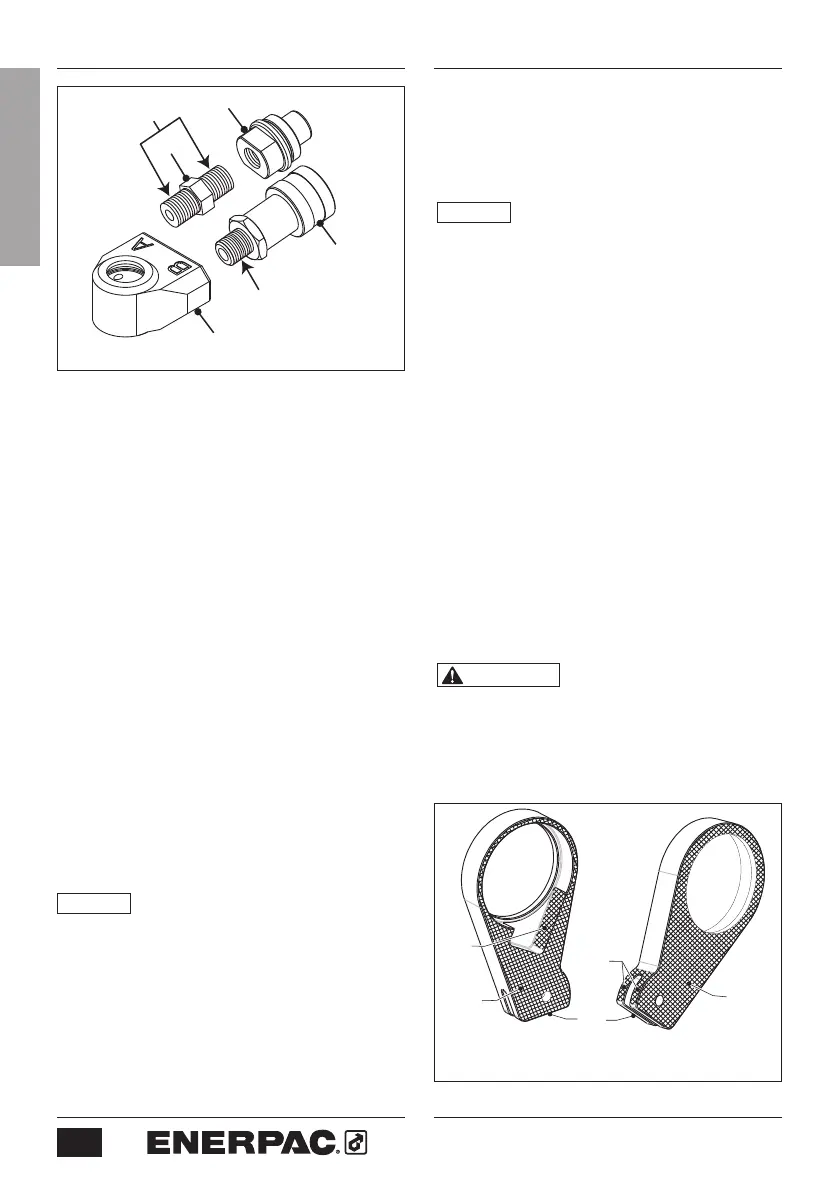

Fig. 18

✜ molybdenum disulphide grease

Fig. 17

◆ Loctite 577

ENGLISH

Loading...

Loading...